Abstract

Freshwater scarcity remains a critical global challenge, prompting the development of sustainable solutions like solar-driven interfacial water evaporation technology. Here, we present a scalable fabrication method for porous monolithic polymer evaporators through olefin metathesis polymerization coupled with NaCl templating. The large-area evaporator (800 × 600 mm²) incorporates amine-capped aniline trimer (ACAT) as a photothermal component within a dicyclopentadiene (DCPD)/cyclooctene (COE) polymer matrix, enabling efficient solar energy absorption and water transport. The optimized SDIE PDCPD-25%COE-10%ACAT exhibits notable performance in seawater desalination, wastewater treatment, and lithium salt enrichment. Under 1 sun irradiation, it achieves a pure water evaporation rate of 3.64 kg m⁻² h⁻¹ with a solar-thermal conversion efficiency of 96.7%, reflecting high energy utilization efficiency. Outdoor experiments under natural sunlight further confirm its operational feasibility, yielding an evaporation rate of 3.33 kg m⁻² h⁻¹. This work provides a viable route for the large-scale implementation of photothermal water treatment technologies, contributing to sustainable freshwater production and resource recovery.

Similar content being viewed by others

Introduction

Freshwater is one of the most critical natural resources for sustaining life and supporting economic development. However, the growing global population and rapid industrialization have led to a dramatic increase in water usage1,2. Climate change and environmental pollution further intensifies this challenge, making it imperative to develop sustainable and energy-efficient technologies for freshwater production. Among the emerging solutions, solar-driven interfacial water evaporation technology has garnered significant attention due to its ability to harness abundant solar energy for seawater desalination and wastewater purification, offering a green and sustainable approach to address freshwater shortages3,4,5,6,7,8.

Solar-driven interfacial water evaporation technology relies on photothermal conversion materials that absorb solar energy and convert it into thermal energy, localized at the solid-liquid-air interface to drive efficient water evaporation. This localized heating minimizes energy loss and significantly enhances evaporation efficiency compared to traditional bulk heating methods9,10. Despite its promise, a major challenge in solar-driven interfacial evaporators (SDIEs) is salt accumulation during seawater desalination, which can degrade performance over time11,12,13. However, this phenomenon also presents an opportunity for resource extraction, as seawater contains valuable elements such as lithium (Li), uranium (U), and gold (Au), albeit in low concentrations14,15,16,17,18,19,20. Recent advancements have demonstrated the potential of SDIEs not only for freshwater production but also for extracting these critical resources. For instance, graphene oxide-based functional hydrogels have achieved notable success in U extraction, highlighting the dual functionality of SDIE in water purification and resource recovery21.

Li, a key component in energy storage technologies, is predominantly extracted from salt-lake brines, which typically contain Li concentrations ranging from 0.01 to 0.2%, such as in Salars de Atacama (Chile SQM) with a Li concentration of 0.15%, and Tibet Damxung (China) with only 0.035%22. Traditional extraction methods rely on natural evaporation, a time-consuming process that can take 12–18 months. SDIEs offers a promising alternative by accelerating evaporation rates and enabling selective separation of Li, thereby improving extraction efficiency and reducing processing time23. This dual capability positions solar-driven interfacial water evaporation as a transformative technology for both water and resource sustainability24.

Photothermal conversion materials are the cornerstone of SDIEs, with carbon-based materials, plasmonic nanoparticles, semiconductors, and organic polymers being widely explored25,26. Among these, organic polymers stand out due to their lightweight nature, structural tunability, and ease of processing27,28. Commonly used polymers such as polypyrrole (PPy)29,30,31, polydopamine (PDA)32,33,34, and polyaniline (PANi)35 have demonstrated excellent photothermal properties. For instance, PPy nanosheets deposited on paper substrates have achieved water evaporation rates of 1.38 kg m⁻² h⁻¹ 36. Furthermore, the integration of hydrophilic polymeric frameworks, such as polyvinyl alcohol, chitosan37, or poly(N-isopropylacrylamide)38, or the development of hybrid systems combining multiple photothermal materials (e.g., PDA with MXene or PDA with PPy)39,40,41, have led to significant performance enhancements. Despite these advancements, polymer-based SDIEs still face critical challenges. However, polymer-based SDIEs still lag behind carbon-based and metallic nanomaterials in terms of evaporation rates, which can exceed 10 kg m⁻² h⁻¹ 42,43. Additionally, the scalability of polymer-based SDIEs remains limited due to complex fabrication processes, high costs, and the use of toxic reagents.

Oligoanilines, with their well-defined molecular structures and tunable photothermal properties, have emerged as promising candidates for SDIEs. Our previous work demonstrated the potential of amine-capped aniline trimer (ACAT) -based SDIEs, achieving evaporation rates of up to 4.32 kg m⁻² h⁻¹ 44,45,46. However, these SDIEs often require toxic reagents like formaldehyde or isocyanates and involve solvent-intensive processes, hindering large-scale production.

In this work, we present a breakthrough in polymer-based SDIEs fabrication by employing a rapid and scalable olefin metathesis polymerization strategy combined with a sodium chloride (NaCl) templating method. Using ACAT as the photothermal material and dicyclopentadiene (DCPD) and cyclooctene (COE) as the polymer matrix, we developed a monolithic polymer-based SDIE, PDCPD-25%COE-10%ACAT, with dimensions of 800 × 600 mm²—the largest polymer-based SDIE reported to date. This scalable and efficient fabrication process, completed in just 5 min, addresses the limitations of previous systems. The resulting SDIE exhibits exceptional performance in seawater desalination, wastewater treatment, and Li salt enrichment, demonstrating its potential for practical applications in addressing global water and resource challenges.

Results and discussion

Preparation and structure optimization

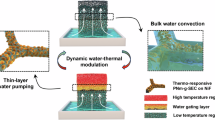

The polymer-based SDIEs were prepared using the salt templating method, as illustrated in Fig. 1. Initially, ground NaCl and ACAT are mixed and evenly spread into a polytetrafluoroethylene mold, which is then placed in a sealed container filled with saturated potassium sulfate solution for 4 h to solidify the NaCl. After solidification, the mold is removed and dried in an oven to eliminate residual moisture, resulting in a robust NaCl template. Subsequently, the Grubbs second-generation catalyst (Grubbs II) is dissolved into a minimal amount of cyclohexylbenzene, and then added to the monomer mixture of DCPD, 5-ethylidene-2-norbornene, and COE. The resulting solution is dripped onto the NaCl template and rapidly cured using a hair dryer, forming a solid composite containing NaCl. Finally, the NaCl is removed via ultrasonic cleaning, yielding a thermosetting porous monolithic polymer-based SDIE embedded with ACAT. This method is not only simple and efficient but also scalable, enabling the production of large-area SDIEs. Using this approach, we successfully fabricated a SDIE with dimensions of 800 × 600 mm², as illustrated in Fig. 2a.

a The photograph of PDCPD-25%COE-10%ACAT with dimensions of 800 × 600 mm². b The stress-strain curves of polymer matrix resin under optimization of monomer ratios. c Curves of the surface temperature of SDIEs with various proportions of ACAT over time under 1 sun. d Infrared thermal images of the surface temperature of SDIE, PDCPD-25%COE-10%ACAT, at different time under 1 sun. Photothermal conversion effects of SDIEs on water surface under 1 sun (e) with various NaCl particle size. f with various thickness. g Water evaporation rate and water evaporation efficiency of polymer-based SDIEs have been reported in recent years.

To enhance the flexibility of the SDIE, we systematically optimized the monomer ratio of DCPD to COE in the polymer matrix. As shown in Fig. 2b, when COE constitutes 10% of the total monomers, the resulting matrix resin (PDCPD-10%COE) exhibits a yield stress of 28 MPa and an elongation at break of 280%. Tensile testing revealed significant strain softening and necking behavior. Increasing the COE content further reduces the yield stress while enhancing the elongation at break. Notably, when COE exceeds 20% of the total monomers, the stress-strain curves no longer exhibit distinct yielding or necking. At 25% COE, the matrix resin (PDCPD-25%COE) achieves a maximum elongation at break of 420%. This improvement is attributed to the incorporation of COE, which introduces flexible alkyl chains into the polymer network, reducing crosslink density and enhancing flexibility. However, further increases in COE content led to a decline in mechanical properties due to excessive reduction in crosslink density.

The photothermal conversion efficiency of the SDIEs is critically dependent on the ACAT content, which facilitates solar energy conversion through molecular thermal vibrations. Varying amounts of ACAT was incorporated into the DCPD-COE copolymer to fabricate porous monolithic polymer-based SDIE. The photothermal performance was evaluated by measuring surface temperatures under 1 sun irradiation using an infrared thermal imager. All SDIEs exhibited rapid temperature increases within the first minute, stabilizing after approximately 10 min. The control SDIE (PDCPD-25%COE without ACAT) reached a surface temperature of only 42 °C after 30 min, whereas SDIEs containing ACAT exceeded 52 °C on surface of water and maintained stability for over 1 h (Fig. 2c). The optimal ACAT content was determined to be 10%, as it yielded the highest surface temperature (54 °C Fig. 2d).

The internal pore structure of the SDIEs, governed by the NaCl particle size, plays a critical role in water transport and evaporation rates. Using NaCl particles of varying mesh sizes (100, 200, and 300 mesh), the evaporation rate decreased with increasing particle size, with the highest rate achieved using 100-mesh NaCl (Fig. 2e). Additionally, the thickness of the SDIEs were optimized to enhance water transport and evaporation efficiency. As shown in Fig. 2f, increasing the thickness from 2 mm to 7 mm initially enhanced the evaporation rate, peaking at 5 mm, before declining. This trend is attributed to the increased difficulty of water transport to the SDIEs surface at greater thicknesses, which reduces the effective evaporation rate.

For performance evaluation, the SDIE was trimmed to a dimension of 10 × 10 mm² to match the effective light spot area of the solar simulator. Under 1 sun illumination, at 26 ± 2 °C and 52 ± 2% humidity, the optimized SDIE (PDCPD-25%COE-10%ACAT) achieved a maximum water evaporation rate of 3.64 kg m⁻² h⁻¹ and a photothermal conversion efficiency of 96.68%. These results surpass those reported in recent literature (Fig. 2g), highlighting the superior performance of our SDIE design47,48,49,50,51,52,53,54,55,56,57,58,59,60,61.

Structure characterization and physical properties

The structural and physical properties of PDCPD-25%COE-10%ACAT were systematically characterized using Fourier transform infrared (FTIR) spectroscopy, X-ray photoelectron spectroscopy (XPS) (SI), contact angle measuring instrument, scanning electron microscopy (SEM), Nitrogen adsorption-desorption analysis (BET method), thermal conductivity tester and solid UV-Vis-NIR spectrometer equipped with an integrating sphere under room temperature conditions. FTIR spectroscopy (Fig. 3a) revealed key functional groups in the photothermal conversion material ACAT, the matrix polymer PDCPD-25%COE, and the SDIE, PDCPD-25%COE-10%ACAT. For ACAT, distinct peaks at 3308 cm⁻¹ (N-H stretching vibration of NH₂) and 3030 cm⁻¹ (C-H stretching vibration in benzene rings) were observed, alongside characteristic aromatic ring skeletal stretching vibrations at 1601 cm⁻¹ and 1501 cm⁻¹. The matrix polymer, PDCPD-25%COE, exhibited peaks at 2920 cm⁻¹ (C-H stretching vibration in alkanes) and 1710 cm⁻¹ (C = C stretching vibration), with additional peaks at 968 cm⁻¹ and 733 cm⁻¹ corresponding to trans- and cis-disubstituted C = C double bonds, respectively, indicating the presence of both configurations in the polymer structure. The FTIR spectrum of PDCPD-25%COE-10%ACAT confirmed the successful incorporation of ACAT, as all characteristic peaks of both components were present.

XPS analysis further validated the composite structure, with the appearance of a symmetrical N1s peak at 400 eV in PDCPD-25%COE-10%ACAT, confirming the presence of ACAT. This result aligns with the FTIR findings, demonstrating the effective integration of ACAT into the polymer matrix.

The hydrophilicity of the SDIEs, a critical factor for efficient water transport, was evaluated through contact angle measurements (Fig. 3b). The contact angle of PDCPD-25%COE-10%ACAT (67.17°) was lower than that of the matrix polymer PDCPD-25%COE (72.15°), indicating enhanced hydrophilicity due to the NH groups in ACAT, which facilitate hydrogen bonding with water molecules.

SEM imaging of PDCPD-25%COE-10%ACAT revealed a hierarchical porous structure (Fig. 3c), comprising both large interconnected pores (up to 150 µm) and smaller mesopores within the pore walls. This morphology ensures efficient water transport and vapor generation. Nitrogen adsorption-desorption analysis (Fig. 3d) further confirmed the bimodal pore size distribution, with mesopores (2–10 nm) and macropores (50–400 nm) contributing to a BET surface area of 1.7696 m²/g and a Langmuir surface area of 3.9711 m²/g. The average pore diameters were 38.187 Å (adsorption) and 9.877 Å (desorption), highlighting the material’s high porosity and surface area.

Thermal management properties were assessed using thermal conductivity tester (Fig. 3e). The thermal conductivity of PDCPD-25%COE-10%ACAT was 0.1391 W m⁻¹ K⁻¹ at 25 °C, increasing slightly to 0.145 W m⁻¹ K⁻¹ at temperatures above 45 °C. This low thermal conductivity ensures effective heat localization at the water-air interface, minimizing heat loss and enhancing evaporation efficiency.

Optical characterization using UV-Vis-NIR spectroscopy (Fig. 3f) demonstrated exceptional light absorption across a broad spectrum (250–2250 nm). The average absorptivity was 98.6% in the ultraviolet-visible range and 99.7% in the near-infrared range, with negligible transmission. This high absorption efficiency, particularly in the NIR region, underscores the material’s superior photothermal conversion capability.

Photothermal performance in seawater desalination

The photothermal performance of the PDCPD-25%COE-10%ACAT was evaluated in seawater desalination experiments under 1 sun irradiation (Fig. 4a). The mass change of residual water was monitored in simulated seawater with varying salt concentrations (Fig. 4b, c). In pure water (0 wt% salt), the SDIE achieved an impressive evaporation rate of 3.64 kg m⁻² h⁻¹. At a salinity of 3.5 wt%, representative of global average seawater, the evaporation rate remained high at 3.32 kg m⁻² h⁻¹. As the salt concentration increased, a gradual decline in evaporation rate was observed, reaching 2.79 kg m⁻² h⁻¹ at 20 wt% salinity. This reduction is attributed to three main factors. (1) The increased density of saline water, which reduces the immersed volume of the SDIE and increases the distance between the SDIE surface and the water-air interface, hindering efficient water transport; (2) Based on Raoult’s law, Na⁺ and Cl⁻ ions occupy surface sites, reducing the number of water molecules at the solution surface and thus the water mole fraction. Consequently, the solution has a lower vapor pressure than pure water, with a more significant drop at higher NaCl concentrations. Since the water evaporation rate is proportional to vapor pressure, it falls as NaCl concentration rises. (3) When NaCl is in water, stronger ion-dipole interactions between ions and water molecules compared to water-water hydrogen bonds strengthen intermolecular forces. As a result, water molecules require more energy to escape the solution surface into the gas phase, thus slowing evaporation rate.

a Diagram of the seawater desalination. b Mass change curves of residual water under 1 sun in various salt concentration. c Water evaporation rate of the SDIE in various salt concentration. d The stability of the SDIE in cyclic water evaporation tests. e Water evaporation rate of the SDIE in various salt concentration at half a year later. f Metal ion concentration of brine before and after evaporation.

To evaluate the long-term stability of the SDIE, cyclic evaporation tests were conducted in simulated seawater (3.5 wt% salinity) over 10 cycles (Fig. 4d). The evaporation rate remained stable at approximately 3.40 kg m⁻² h⁻¹, demonstrating the robust durability of the polymer-based evaporator. Furthermore, the same sample was retested after a 6-month interval (Fig. 4e), revealing only a 3.64% decrease in evaporation rate (to 3.28 kg m⁻² h⁻¹) in 3.5 wt% saline water. In higher salinity conditions (10 wt% and 20 wt%), the evaporation rates decreased by 4.25% and 1.8%, respectively. These results highlight the exceptional salt resistance and long-term stability of the PDCPD-25%COE-10%ACAT, making it suitable for prolonged use in harsh saline environments.

The quality of the desalinated water was assessed by measuring the concentrations of key ions (Na⁺, K⁺, Ca²⁺, and Mg²⁺) in the collected condensate using inductively coupled plasma optical emission spectrometry (ICP-OES). As shown in Fig. 4f, the concentrations of these ions were significantly reduced during the solar-driven desalination process. Specifically, the concentrations of Na⁺, K⁺, Ca²⁺, and Mg²⁺ in the purified water were reduced to 0.09%, 0.04%, 0.66%, and 0.53% of their initial levels, respectively. These values are well below the World Health Organization (WHO) drinking water standards, confirming the suitability of the collected condensate for direct human consumption.

Photothermal performance in sewage treatment

Water pollution, particularly from dye and heavy metal contaminants, is a major contributor to global freshwater scarcity. To address this challenge, we evaluated the performance of the PDCPD-25%COE-10%ACAT in treating wastewater containing organic dyes and heavy metal ions. As shown in Fig. 5a, b, the SDIE demonstrated exceptional stability and efficiency across various wastewater solutions, maintaining a consistent water evaporation rate of approximately 3.3 kg m⁻² h⁻¹. This performance was observed in the presence of common organic dyes, including methylene blue, methyl orange, and rhodamine B, as well as heavy metal ions such as Zn²⁺, Cd²⁺, and Cr³⁺. These results highlight the robustness of PDCPD-25%COE-10%ACAT in diverse wastewater environments, underscoring its potential for practical applications in water purification.

To quantify the pollutant removal efficiency, the concentrations of organic dyes in the collected condensate were analyzed using high-performance liquid chromatography (HPLC). As illustrated in Fig. 5c–e, the absorbance of treated condensate water for methylene blue, methyl orange, and rhodamine B was nearly zero, with the condensate water appearing colorless. This indicates near-complete removal of these dyes, with removal efficiencies approaching 100%. Similarly, ICP-OES analysis revealed a dramatic reduction in heavy metal ion concentrations. The levels of Zn²⁺, Cd²⁺, and Cr³⁺ in the condensate water decreased by 3–4 orders of magnitude compared to the initial concentrations, achieving removal rates exceeding 99%.

Photothermal performance in lithium salt enrichment

The rapid proliferation of electronic devices, such as electric vehicles and energy storage systems, has driven an unprecedented surge in global demand for lithium (Li) resources. However, the extraction of high-purity Li salts from natural sources, including salt-lake brines and seawater, is significantly hindered by the presence of interfering ions such as Na⁺ and Mg²⁺. To address this challenge, we investigated the performance of the PDCPD-25%COE-10%ACAT for selective salt separation and Li⁺ enrichment.

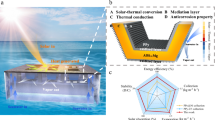

As illustrated in Fig. 6a, a 10 × 10 mm² PDCPD-25%COE-10%ACAT was respectively floated in saturated aqueous solutions of NaCl, MgCl₂, or LiCl under simulated solar irradiation (1000 W/m²) to evaluate salt precipitation behavior. Within 3 h of illumination, NaCl crystals began to form on the evaporator surface, with the crystal quantity increasing over time. Notably, the NaCl crystals amassed by PDCPD-25%COE-10%ACAT were preponderantly deposited on the outer insulating layer. Subsequent to 5 h of illumination, even upon further prolongation of the time, the amount of NaCl crystals adhered to the surface of the PDCPD-25%COE-10%ACAT exhibited minimal variation. A similar trend was observed in pure MgCl₂ solution, where MgCl₂ crystals preferentially precipitated at the periphery of the SDIE. This unique salt precipitation behavior not only facilitates efficient salt collection but also enhances the SDIE’s utilization efficiency and operational lifespan.

a Photographs of the SDIE in every saturated aqueous solution of NaCl, MgCl2 or LiCl under 1 sun with various time. b Mass change of the precipitated salts. c Mass concentration ratio of Mg²⁺ to Li⁺ in the mixture solution after evaporation obtained from ICP-OES. d The XPS result of precipitated salts.

In contrast, no visible LiCl crystals were observed on the SDIE surface after 12 h of illumination in LiCl solution. To quantify salt precipitation, the SDIE was periodically removed, cleaned, and analyzed (Fig. 6b). During the initial 5 h, NaCl and MgCl₂ exhibited comparable precipitation rates. However, beyond this period, MgCl₂ precipitation significantly outpaced NaCl, while LiCl precipitation remained negligible. This phenomenon can be attributed to the Mulliken charge differences among the ions: Mg²⁺ > Na⁺ ≫ Li⁺. The stronger electrostatic interaction between Cl⁻ and Mg²⁺ promotes the formation of contact ion pairs, leading to faster MgCl₂ precipitation. As evaporation progresses, the increasing Mg²⁺ concentration further accelerates this process. Consequently, the SDIE effectively separates Li⁺ from Na⁺ and Mg²⁺, enriching Li⁺ in the residual brine and improving Li salt extraction efficiency.

To further validate the SDIE’s performance in mixed solutions, the PDCPD-25%COE-10%ACAT was tested in a MgCl₂-LiCl mixture under 1 sun solar irradiance. ICP-OES analysis (Fig. 6c) revealed that the Mg²⁺/Li⁺ mass concentration ratio (\({C}_{{{Mg}}^{2+}}/{C}_{{{Li}}^{+}}\)) in the residual solution decreased rapidly from 5.0:1 to 3.2:1 within the first 10 h due to MgCl₂ crystallization. Beyond this period, the ratio declined more gradually, reaching 2.6:1 after 30 h. This slowdown is likely due to MgCl₂ deposition on the SDIE surface, which partially obstructs light absorption. XPS analysis of the precipitated salts after 30 h (Fig. 6d) confirmed the presence of Mg²⁺ but negligible Li⁺, consistent with the higher diffusion coefficient of Li⁺, which impedes its precipitation compared to Mg²⁺.

Outdoor experiments

To evaluate the practical application potential of the PDCPD-25%COE-10%ACAT, outdoor experiments were conducted under natural sunlight using simulated seawater with a salinity of 3.5%. The tests were performed on August 26, 2024, in Chengdu, Sichuan Province, China, from 9:30 to 17:30. The experimental setup is illustrated in Fig. 7a, b.

Under solar irradiation, a significant amount of water droplets rapidly condensed on the surface of the collection device, demonstrating the efficient evaporation and condensation capabilities of the SDIE (Fig. 7b). Throughout the testing period, the solar irradiance intensity followed a parabolic trend, increasing to a maximum and then decreasing, while the ambient humidity exhibited an inverse pattern, initially decreasing and then slightly rising. The water evaporation rate closely correlated with solar irradiance, showing a corresponding increase and subsequent decrease over time (Fig. 7c).

The peak performance was observed between 12:30 and 13:30, when the solar flux reached its maximum value of 0.807 kW m⁻². Under these conditions, the ambient temperature was 45.2 °C, the relative humidity was 22%, and the evaporation rate peaked at 3.33 kg m⁻² h⁻¹. Notably, even during periods of low solar intensity in the early morning and late afternoon, the evaporation rate remained robust, achieving approximately 2 kg m⁻² h⁻¹. This consistent performance across varying solar conditions highlights the reliability and efficiency of the PDCPD-25%COE-10%ACAT in real-world applications.

Overall, we successfully developed a novel polymer-based SDIE, PDCPD-25%COE-10%ACAT, using olefin metathesis and NaCl templating. This porous monolithic SDIE, with a dimensions of up to 800 × 600 mm², shows excellent performance after optimization, achieving a water evaporation rate of 3.64 kg m⁻² h⁻¹ and an efficiency exceeding 96.7%. In seawater desalination, it maintains stable performance across multiple cycles and reduces ion concentrations in the condensate to meet drinking water standards. For sewage treatment, it retains high evaporation rates and photothermal efficiency in challenging environments, enabling nearly complete pollutant removal. In resource recovery, it selectively separates lithium salts from mixed salt solutions, improving lithium extraction efficiency. Natural sunlight field tests confirm its practicality, with evaporation rates ranging from 2 to 3.33 kg m⁻² h⁻¹. This research not only provides a robust platform for freshwater generation but also establishes a new paradigm for integrated water treatment and resource recovery.

Methods

Characterization

FTIR spectroscopy was performed using a Bruker VERTEX70 spectrometer to identify functional groups and chemical bonds. XPS analysis was conducted on an Axis Supra instrument (Shimadzu Kratos) equipped with an Al Kα X-ray source (15 kV, 25 W), with a beam focused on a 700 × 300 μm² area. The binding energies were calibrated using the adventitious carbon (C1s) peak at 284.8 eV. Contact angle measurements were carried out using a goniometer (Shanghai Suolun, SL150) to evaluate surface hydrophilicity. SEM images were acquired using an FEI Quanta 250 microscope to examine the surface morphology and pore structure. The pore size distribution and specific surface area were determined using a BET analyzer (Micromeritics ASAP 2460). Optical absorption spectra were recorded on a UV-Vis-NIR spectrometer (PerkinElmer, Lambda 950) equipped with an integrating sphere, covering a wavelength range of 250–2250 nm. Mechanical properties were assessed using a universal testing machine (INSTRON, 3367). Water evaporation rates were measured under 1 sun simulated sunlight (Newport Oriel Sol3A™ Xe lamp) using a precision balance (Mettler Toledo ME204E). Thermal imaging and temperature profiles were obtained using an infrared thermal camera (HIKMICRO, H16). The concentrations of organic dyes and metal ions in water were quantified using high-performance liquid chromatography (HPLC, Agilent 1290) and inductively coupled plasma optical emission spectroscopy (ICP-OES, PerkinElmer Optima 8000), respectively.

The devices and testing methods for the evaporation rates of the PDCPD-25%COE-10%ACAT in brines with different concentrations and wastewaters containing various pollutants, as well as for the quality testing of the collected condensate water, are presented in in the Supporting Information.

Synthesis of photothermal conversion material (ACAT)

The photothermal conversion material, ACAT, was synthesized via an oxidative coupling reaction. Briefly, bis(4-aminophenyl)amine sulfate hydrate (1 equivalent) and aniline (1 equivalent) were reacted with ammonium persulfate (0.8 equivalent) as the oxidant in a 1 M HCl solution. The reaction mixture was stirred at −5 oC for 6 h, followed by filtration, washing, and drying to obtain the final product.

Fabrication of solar-driven interfacial evaporator (PDCPD-25%COE-10%ACAT)

The porous monolithic polymer-based SDIE, PDCPD-25%COE-10%ACAT, was fabricated through a combination of olefin metathesis and a sodium chloride (NaCl) templating method. In a typical procedure, NaCl (1813 g) and ACAT (308 g) were packed into a polytetrafluoroethylene mold (800 × 600 × 5 mm) and exposed to a saturated potassium sulfate solution for 4 h to ensure uniform moisture distribution. The template was then dried to remove excess water. Separately, Grubbs second-generation catalyst (Grubbs II, 960 mg) was dissolved in cyclohexylbenzene (60 mL) and added to a monomer mixture comprising dicyclopentadiene (DCPD, 1056 g), 5-ethylidene-2-norbornene (48 g), and cyclooctene (COE, 294 g). The resulting solution was poured into the NaCl template and polymerized using a hair dryer to initiate the reaction. After polymerization, the monolithic block was removed from the mold, and the NaCl template was leached out by ultrasonication in deionized water. The final porous polymer foam was dried at 60 °C for 24 h to obtain the SDIE.

Data availability

No datasets were generated or analysed during the current study.

References

Chaplin-Kramer, R. et al. Global modeling of nature’s contributions to people. Science 366, 255–258 (2019).

Mekonnen, M. M. & Hoekstra, A. Y. Four billion people facing severe water scarcity. Sci. Adv. 2, e1500323 (2016).

Wu, X. et al. Interfacial solar evaporation: from fundamental research to applications. Adv. Mater. 36, 2313090 (2024).

Kim, H. T. et al. Recent advances in high-rate solar-driven interfacial evaporation. Adv. Sci. 11, 2401322 (2024).

Peng, G. et al. Potential and challenges of improving solar still by micro/nano-particles and porous materials - a review. J. Clean. Prod. 311, 127432 (2021).

Tao, P. et al. Solar-driven interfacial evaporation. Nat. Energy 3, 1031–1041 (2018).

Dang, C. et al. System integration for solar-driven interfacial desalination. Device 2, 100361 (2024).

Xie, M. et al. A three-dimensional antifungal wooden cone evaporator for highly efficient solar steam generation. npj Clean. Water 6, 12 (2023).

Ghasemi, H. et al. Solar steam generation by heat localization. Nat. Commun. 5, 4449 (2014).

Sinhamahapatra, A. & Kumar, A. Review of the progress of solar-driven interfacial water evaporation (siwe) toward a practical approach. Energy Adv. 2, 574–605 (2023).

Xia, Q. et al. Solar-driven abnormal evaporation of nanoconfined water. Sci. Adv. 10, eadj3760 (2024).

Xu, K., Wang, C., Li, Z., Wu, S. & Wang, J. Salt mitigation strategies of solar-driven interfacial desalination. Adv. Funct. Mater. 31, 2007855 (2021).

Yuan, P. et al. Spontaneous salt-preventing solar–thermal water evaporator with a high evaporation efficiency through dual-mode water transfer. ACS Appl. Mater. Interfaces 14, 15549–15557 (2022).

Abney, C. W., Mayes, R. T., Saito, T. & Dai, S. Materials for the recovery of uranium from seawater. Chem. Rev. 117, 13935–14013 (2017).

Odziomek, M. et al. Hierarchically structured lithium titanate for ultrafast charging in long-life high capacity batteries. Nat. Commun. 8, 15636 (2017).

Santoro, S. et al. Lithium recovery through ws2 nanofillers-promoted solar photothermal membrane crystallization of licl. Desalination 546, 116186 (2023).

Ma, X., Jia, X., Yao, G. & Wen, D. Double-sided suspending evaporator with top water supply for concurrent solar evaporation and salt harvesting. ACS Sustain. Chem. Eng. 10, 12843–12851 (2022).

Tian, Y. et al. Solar-driven multistage device integrating dropwise condensation and guided water transport for efficient freshwater and salt collection. Environ. Sci. Technol. 58, 7335–7345 (2024).

Cui, W.-R., Zhang, C.-R., Liang, R.-P. & Qiu, J.-D. Covalent organic framework hydrogels for synergistic seawater desalination and uranium extraction. J. Mater. Chem. A 9, 25611–25620 (2021).

Sharkh, B. A. et al. Seawater desalination concentrate-a new frontier for sustainable mining of valuable minerals. npj Clean. Water 5, 9 (2022).

Li, T. et al. Photothermal-enhanced uranium extraction from seawater: aA biomass solar thermal collector with 3d ion-transport networks. Adv. Funct. Mater. 33, 2212819 (2023).

Xu, S. et al. Extraction of lithium from chinese salt-lake brines by membranes: design and practice. J. Membr. Sci. 635, 119441 (2021).

Zhang, S. et al. Solar-driven membrane separation for direct lithium extraction from artificial salt-lake brine. Nat. Commun. 15, 238 (2024).

Song, Y., Fang, S., Xu, N. & Zhu, J. Solar-driven interfacial evaporation technologies for food, energy and water. Nat. Rev. Clean. Technol. 1, 55–74 (2025).

Liu, Y. et al. Advances and challenges of broadband solar absorbers for efficient solar steam generation. Environ. Sci. Nano 9, 2264–2296 (2022).

Zhu, L. et al. Advances in photothermal regulation strategies: from efficient solar heating to daytime passive cooling. Chem. Soc. Rev. 52, 7389–7460 (2023).

Mao, S. et al. Recent developments of hydrogel based solar water purification technology. Mater. Adv. 3, 1322–1340 (2022).

Zhao, M. et al. High-performance organic photothermal material based on fusion of the donor–acceptor structure for water evaporation and thermoelectric power generation. ACS Appl. Energy Mater. 5, 15758–15767 (2022).

Zhang, L., Tang, B., Wu, J., Li, R. & Wang, P. Hydrophobic light-to-heat conversion membranes with self-healing ability for interfacial solar heating. Adv. Mater. 27, 4889–4894 (2015).

Zhao, F. et al. Highly efficient solar vapour generation via hierarchically nanostructured gels. Nat. Nanotech. 13, 489–495 (2018).

Xu, Y. et al. Flexible and efficient solar thermal generators based on polypyrrole coated natural latex foam for multimedia purification. ACS Sustain. Chem. Eng. 8, 12053–12062 (2020).

Wang, Z. et al. Mussel-inspired surface engineering for water-remediation materials. Matter 1, 115–155 (2019).

Wang, X. et al. Bioinspired interfacial spontaneous growth of zno nanocatalysts onto recycled textiles as a sustainable approach for water purification. Glob. Chall. 7, 2200110 (2023).

Chen, Y. et al. Ultra-robust, high-adhesive, self-healing, and photothermal zwitterionic hydrogels for multi-sensory applications and solar-driven evaporation. Mater. Horiz. 10, 3807–3820 (2023).

Yin, X. et al. Macroporous double-network hydrogel for high-efficiency solar steam generation under 1 sun illumination. ACS Appl. Mater. Interfaces 10, 10998–11007 (2018).

Wang, X., Liu, Q., Wu, S., Xu, B. & Xu, H. Multilayer polypyrrole nanosheets with self-organized surface structures for flexible and efficient solar–thermal energy conversion. Adv. Mater. 31, 1807716 (2019).

Zhou, X., Zhao, F., Guo, Y., Rosenberger, B. & Yu, G. Architecting highly hydratable polymer networks to tune the water state for solar water purification. Sci. Adv. 5, eaaw5484 (2019).

Lim, H. W., Park, S. H. & Lee, S. J. 3d thermoresponsive hydrogel with enhanced water uptake and active evaporation for effective interfacial solar steam generation. Desalination 550, 116368 (2023).

Chen, Y. et al. An integrated highly hydrated cellulose network with a synergistic photothermal effect for efficient solar-driven water evaporation and salt resistance. J. Mater. Chem. A 9, 15482–15492 (2021).

Yang, Y. et al. A bioinspired antibacterial and photothermal membrane for stable and durable clean water remediation. Mater. Horiz. 10, 268–276 (2023).

Wang, X. et al. Toward multitasking solar desalination: a janus and scalable paper evaporator with light trapping, heat confinement, salt resistance, and pollutant degradation. J. Mater. Chem. A 11, 10287–10296 (2023).

Yang, Y. et al. A diode-like scalable asymmetric solar evaporator with ultra-high salt resistance. Adv. Funct. Mater. 33, 2210972 (2023).

Bae, K. et al. Flexible thin-film black gold membranes with ultrabroadband plasmonic nanofocusing for efficient solar vapour generation. Nat. Commun. 6, 10103 (2015).

Chen, Q. et al. A durable monolithic polymer foam for efficient solar steam generation. Chem. Sci. 9, 623–628 (2018).

Li, R. et al. A single component, single layer flexile foam evaporator with the higher efficiency for water generation. Adv. Mater. 36, 2402016 (2024).

Wu, M. et al. Hydrophilic polymer foam as a monolithic interfacial solar evaporator with rapid self-cleaning, high evaporation efficiency, and salt resistance. Adv. Funct. Mater. 34, 2410729 (2024).

He, J. et al. High-performance salt-rejecting and cost-effective superhydrophilic porous monolithic polymer foam for solar steam generation. ACS Appl. Mater. Interfaces 12, 16308–16318 (2020).

Li, X. et al. A lotus-petiole-inspired hierarchical design with hydrophilic/hydrophobic management for enhanced solar water purification. Adv. Funct. Mater. 33, 2302019 (2023).

Wang, Z., Wu, X., He, F., Peng, S. & Li, Y. Confinement capillarity of thin coating for boosting solar-driven water evaporation. Adv. Funct. Mater. 31, 2011114 (2021).

Guo, Y. et al. Highly elastic interconnected porous hydrogels through self-assembled templating for solar water purification. Angew. Chem. Int. Ed. 61, e202114074 (2021).

Wang, Y., Li, W., Wei, Y. & Chen, Q. Recyclable monolithic vitrimer foam for high-efficiency solar-driven interfacial evaporation. ACS Appl. Mater. Interfaces 15, 14379–14387 (2023).

Chaule, S. et al. Rational design of a high performance and robust solar evaporator via 3d-printing technology. Adv. Mater. 33, 2102649 (2021).

Guo, Y. et al. Tailoring surface wetting states for ultrafast solar-driven water evaporation. Energy Environ. Sci. 13, 2087–2095 (2020).

Qu, M. et al. Multi-functional janus hollow solar evaporator based on copper foam for non-contact high-efficiency solar interfacial distillation. ACS Appl. Mater. Interfaces 15, 36999–37010 (2023).

Meng, S. et al. Interfacial radiation-absorbing hydrogel film for efficient thermal utilization on solar evaporator surfaces. Nano Lett. 21, 10516–10524 (2021).

Ping, Z. et al. A universal Cl-pedot coating strategy based on oxidative chemical vapor deposition toward solar-driven multifunctional energy management. Adv. Funct. Mater. 32, 2208965 (2022).

Geng, Y. et al. Bioinspired fractal design of waste biomass-derived solar–thermal materials for highly efficient solar evaporation. Adv. Funct. Mater. 31, 2007648 (2020).

Ivan, M. N. A. S. et al. Waste egg tray and toner-derived highly efficient 3d solar evaporator for freshwater generation. ACS Appl. Mater. Interfaces 14, 7936–7948 (2022).

Yang, Y. et al. A 3d-printed integrated mxene-based evaporator with a vertical array structure for salt-resistant solar desalination. J. Mater. Chem. A 9, 23968–23976 (2021).

Li, Z. et al. Tailorable lignocellulose-based aerogel to achieve the balance between evaporation enthalpy and water transport rate for efficient solar evaporation. ACS Appl. Mater. Interfaces 15, 11827–11836 (2023).

Lu, Q., Shi, W., Yang, H. & Wang, X. Nanoconfined water-molecule channels for high-yield solar vapor generation under weaker sunlight. Adv. Mater. 32, 2001544 (2020).

Acknowledgements

The authors gratefully acknowledge Dr. Conglin Yang and Dr. Xue Jiang from Sichuan Normal University for their assistance with SEM and ICP-OES measurements. This work was supported by the National Natural Science Foundation of China (No. 52103346 and 21788102), the Laboratory Innovation Research Project of Sichuan Normal University (No. XJ20231017 and XJ20231036), the foundation of Key Laboratory of Special Wastewater Treatment, Sichuan Province Higher Education System (No. 202108 and SWWT2022-7), and the foundation of Northwest Oasis Water-saving Agriculture Key Laboratory, Ministry of Agriculture and Rural Affairs (No. 2023OWSL-02).

Author information

Authors and Affiliations

Contributions

Yuefeng Bai and Yen Wei conceived the study, designed the research framework, and supervised the project. Chunyang Jiang and Ziyi Yan developed the experimental methodology, conducted the experiments, and collected the data. Ruoxin Li and Mingrui Wu performed data validation, ensured reproducibility, and conducted statistical analyses. Wen-Hao Yu, Hong-Mei Chen, Ping Hu, Ke-Qin Zhao, and Kangmin Niu contributed to resource provision, including materials, instrumentation, and technical support. Chunyang Jiang and Yuefeng Bai drafted the initial manuscript. Yanbo Liu, Shih-Hsin Ho, Wei Wang, and Yen Wei critically reviewed and edited the manuscript, providing intellectual input and improving the overall quality. Yuefeng Bai, Hong-Mei Chen, Ruoxin Li and Yen Wei secured funding for the research. All authors participated in the discussion, interpretation of the results, and approved the final version of the manuscript.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Jiang, C., Yan, Z., Bai, Y. et al. Scalable, high-efficiency porous monolithic polymer foam for solar-driven interfacial water evaporation and lithium extraction. npj Clean Water 8, 47 (2025). https://doi.org/10.1038/s41545-025-00474-2

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41545-025-00474-2