Abstract

A methodology combining physical experiments with simulation was employed to acquire contact parameters of sandy soil precisely for planting tiger nuts in the desert area of Xinjiang. The stacking angle under different parameter combinations was applied as a response value. Through the Plackett–Burman test, several factors that have a significant influence were determined. The steepest ascent test was conducted to establish the finest scope of values for these parameters. The stacking angle was considered the response variable, and non-linear tools were used to optimize these parameters for simulation. The findings showed that applying response surface methodology (RSM) resulted in a relative error of 1.24%. In the case of BP-GA, the relative error compared to the physical test value was 0.34%, while for BP, it was 2.18%. After optimization using Wavelet Neural Network (WNN), the relative error was reduced to only 0.15%. Results suggest that WNN outperforms the RSM model, and the sandy soil model and parameters generated using WNN can be effectively utilized for discrete element simulation research.

Similar content being viewed by others

Introduction

In China, Xinjiang has the most extensive range and most immense expanse of deserts. The total desert area in Xinjiang spans approximately 420,000 km2, accounting for 26.12% of the province's total area1. In recent years, the domestic desert industry has experienced significant growth, and Xinjiang has made notable achievements in its development2. However, the industrialization of certain economic crops in desert regions has yet to catch up with the overall progress of the desert industry. For instance, sowing and harvesting crops like tiger nuts need more suitable mechanical equipment, leading to low production efficiency and high labor costs. The above things, in turn, hinder the development of Xinjiang's desert industry. Consequently, it becomes crucial to study and develop mechanical equipment that can mechanize the production of economic crops in Xinjiang's desert areas. The first step in researching and developing such equipment involves gaining a comprehensive understanding of the characteristics of sandy soil for planting economic crops in Xinjiang.

With the progress in high-tech, Discrete Element Methodology (DEM) has gained popularity in investigating bulk materials3,4. The discrete element method is a numerical simulation method specifically designed to solve problems in discontinuous media. The basic principle of this method is to treat the cleavage material as a discrete material and the cleavage surface between materials, allowing for material translation, rotation, and deformation. In contrast, the cleavage surface can be compressed, separated, or slid. It can have large displacement, rotation, sliding, and even block separation inside, which can simulate the nonlinear prominent deformation characteristics in cleavage materials more realistically. DEM enables a comprehensive and systematic examination of the motion characteristics of bulk materials. It not only facilitates the optimization of structural and operational parameters of mechanical devices but also enhances development efficiency, improves mechanical performance, and reduces costs. Parameter calibration is a valuable approach to accurately obtaining material characteristic parameters in material characteristic research. Currently, scholars in related research fields have conducted studies on parameter calibration of agricultural bulk materials adopting DEM. For example, Zhang et al.5 introduced a technique for calibrating interaction parameters between sand and soil using a combined approach, and examined the effects of varying masses and calibration methods on the repose angle. The findings revealed that the particle morphology has a noteworthy influence on the static friction coefficient. Wu6 employed orthogonal experimental methods to calibrate the interaction parameters among sand particles. The simulated deposition angle was determined to be 26.586°, exhibiting a relative error of 1.22%, thus confirming the accuracy of the simulation outcomes. Wang7 investigated the calibration of contact parameters among sand particles, with findings indicating that the variance between virtual simulation and actual testing was less than 5.1%. Wu8, Lin9, and Wang10 analyzed and calibrated the contact parameters of manure. All three studies confirmed the viability of the methodologies, thereby yielding commendable experimental outcomes. Coetzee11 and Pasha12 demonstrated that particle models of various shapes necessitated parameters during the simulation, which should be calibrated via experimentation. Moreover, Liu, Wang, and Liu13,14,15 calibrated contact parameters of crops such as wheat, corn, and mini-potatoes, respectively, providing valuable references for parameter optimization and performance analysis of crop harvesting mechanization. The above studies have all adopted the discrete element calibration method, which allows for relative motion between individual cells, does not necessarily meet the conditions of continuous displacement and deformation coordination, has fast calculation speed, and requires small storage space to solve problems with large displacement and nonlinearity, and has achieved promising experimental results.

Furthermore, machine learning techniques have found extensive applications in engineering. For instance, references16,17,18 demonstrate modeling using the cosine amplitude method, and relevant algorithms were then employed to analyze and predict various engineering issues. Simultaneously, numerous machine learning studies to solve engineering problems have proposed several valuable and innovative designs19,20,21,22.

The studies mentioned above have yielded promising results; however, there is still scope for further improvement. Based on the study mentioned above, this research focuses on sandy soil found in the desert areas of Xinjiang, where tiger nuts are cultivated. A combined approach was utilized to calibrate the contact parameters of sandy soil's discrete elements23. Afterward, the obtained crucial parameters were optimized and fitted by applying non-linear tools, followed by the acquisition and comparison of predicted values. Consequently, a model was developed, serving as a conceptual background for the design of devices in the mechanized production of economic crops like tiger nuts.

Materials and methods

Materials

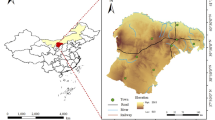

The sandy soil was acquired from a tiger nut plantation in the 54th Regiment of the Third Division in Xinjiang. The 54th Regiment is in Shache County, on the southwestern frontier of Xinjiang, at the northern foothills of the Kunlun Mountains, and south of the Pamir Plateau. It lies within the mid-upper reaches of the Yarkand River alluvial fan plain, positioned between the Taklamakan Desert and the Bugur Desert, with the terrain sloping from west to east. The geographical coordinates are approximately between 76°1′57″ to 77°46′30″ E longitude and 37°27′30″ to 39°15ʹ N latitude. A bulk density meter was employed to determine its density. The standard for the determination of the particle size distribution is GB/T 50123-2019. The particle size distribution was determined by screening soil by applying a standard particle size sieve. Additionally, moisture content was measured, as presented in Table 1. The intrinsic parameters for sandy soil and steel plate were determined based on previous studies6,24,25,26 and the GEMM database of EDEM, as listed in Table 2.

As an intrinsic characteristic of bulk materials, stacking angle can provide insights into their flow and friction properties27,28,29. A combinatorial approach11 was employed to calibrate parameters. Injection methodology was utilized to measure the actual stacking angle. Plackett–Burman design, conducted using Design-Expert 8.06, was applied for a multi-factor significance screening test and analysis to identify parameters that have a crucial influence on stacking angle. Box-Behnken design RSM was applied to form and ameliorate a regression model. Compared to the central composite design, the Box-Behnken design requires fewer trials and typically features a more uniform layout of test points. Additionally, it excludes pivot points on the boundaries of the test range, thereby reducing the extreme conditions of the experiment. Therefore, this study opted for the Box-Behnken design. The actual stacking angle was adopted as the objective value. A regression model was also used to determine the combination of crucial parameters. Subsequently, a simulation was performed by applying optimal parameters. The simulated value was contrasted with the actual value to validate the validity of the calibrated parameters.

Physical model

Based on the related investigations in the paper30,31,32, injection methodology was adopted following GB 11986-89/ISO 4324-1977. The measuring device is depicted in Fig. 1. The lower mouth of the funnel had an inner diameter of 10 mm, while the funnel itself had a taper angle of 60°. The tray, with a diameter of 100 mm, had a height of 25 mm. The distance between the lower mouth and the upper surface of the tray was measured to be 75 mm. During the procedure, sandy soil particles in the funnel fell on the tray through the funnel mouth and formed a steady pile of particles. First, the stacking angle image was captured from the side. This image was then imported into MATLAB software for processing to obtain the angle. The experiment was conducted five times. The mean calculated value of the stacking angle was computed as 32.15°. The results of the physical experimental equipment are shown in Figs. 1 and 2.

Simulation model configuration

Contact model betwixt particles

The hertz-Mindlin (no slip) contact model is known for its accuracy in force calculation. This model proves highly efficient given the minimal cohesive action betwixt particles in sandy soil33.

Assuming that two particles with radii R1 and R2 are brought into elastic contact, the mathematical calculation for normal overlap α is

\({\vec{\text{r}}}_{{1}}\) and \({\vec{\text{r}}}_{{2}}\) are sphere center position vector.

Contact radius of contact surface is \(a\).

\(R^{ * }\) is equivalent particle radius, which is computed as follow,

Normal force betwixt particles \(F_{n}\) is

\(E^{ * }\) is equivalent elastic modulus, which is computed as follow,

where, \(E_{1}\) represents the elastic modulus of Particle 1, \(\nu_{1}\) denotes the Poisson's ratio of Particle 1, \(E_{2}\) represents the elastic modulus of Particle 2, and \(\nu_{{2}}\) denotes the Poisson's ratio of Particle 2.

Normal damping force can be acquired by later calculation.

m* means equivalent mass, which is acquired as follow,

where, \(\beta\) is damping ratio, \(e\) is restitution factor, \(\upsilon_{{\text{n}}}^{{{\text{rel}}}}\) is normal component of relative velocity, and \(S_{{\text{n}}}\) means normal stiffness.

\(S_{\tau }\) means tangential stiffness. \(\delta_{\tau }\) is tangential overlap. Besides, \(G^{ * }\) means equivalent shear modulus.

\(\upsilon_{\tau }^{rel}\) means tangential component of relative velocity.

Rolling friction be described as,

where, \(\mu_{{\text{r}}}\) means rolling friction coefficient, \(R_{{\text{i}}}\) represents distance from contact point to center of mass. In addition, \(\omega_{{\text{i}}}\) is unit angular vector of object at contact point.

Establishment of geometric model

To establish a suitable particle model, the mass distribution of sandy soil particles ranging from 0 to 0.25 mm was scrutinized, and it was found that they accounted for 92.29% of the total mass among the selected test samples, making them representative of the overall sand sample. Therefore, these particles were selected for modeling purposes. It should be noted that the size and shape of the sand particle impact the results and the computational efficiency of the computer. Considering laboratory conditions and physical properties of sand particles, spherical particles with a size of 1 mm were selected.

Using a physical test model as a basis, a model was created in SolidWorks software, which was integrated into EDEM as a simulation model for the funnel device, utilizing the Hertz-Mindlin (no slip) contact model. Figures 3 and 4 display particle model and funnel model, respectively.

It is determined that the initial radius of particles generated in the simulation procedure should be 1 mm, and they were randomly generated. To prevent the generation of tiny particles, the radius of the generated particles was limited to between 0.5 and 1.25 times the initial radius.

Dynamic generation of particles in the funnel was performed using a virtual particle factory above the funnel. The overall weight produced was 0.45 kg, with a rate of 0.2 kg/s. The time interval for data storage was established as 0.01 s, while the fixed time step was 20% of the Rayleigh time step. Furthermore, the mesh size was three times the smallest spherical element size6,34,35. Values of the other parameters are shown in Table 3.

Test methodology

RSM test methodology

Plackett Burman design (PBD) screening experiment

A PBD screening experiment was adopted to ascertain the importance of every individual factor. The test examines the correlation between objective response and every individual factor, contrasting the difference between the two levels of every individual factor. The stacking angle of sandy soil was selected as the response value for screening contact parameters. Two levels were chosen for every individual of the six factors. Simulation parameters were determined based on characteristics of sandy soil used for planting economic crops in desert areas of Xinjiang. Table 4 shows levels of factors, along with corresponding symbols.

Steepest ascent test

The steepest ascent test is a methodology that can quickly identify the area with optimal response value while minimizing the number of tests required. It was conducted by increasing or decreasing values of significant parameters according to predetermined step length36. For residual parameters, the median values were selected. Specifically, A was 0.4, C was 0.2, and F was 0.22. The test scheme can be found in Table 7, and the relative error (N, %) is shown in the formula (14).

where, \(\sigma\) is stacking angle of simulation test (°). \(\theta\) is stacking angle of physical test (°).

Box Behnken design response surface experiment

Based on the principle of response surface design37, the Box-Behnken test was conducted with three levels of significant parameters (low, medium, and high). Additionally, five central points were included to estimate the error. Factor values are provided in Table 5. Factors corresponding to each symbol are consistent with Table 4.

Machine learning algorithm

The Back Propagation (BP) algorithm is a feedforward learning algorithm that utilizes a multi-layer perceptron, also known as BP neural network, to perform backpropagation. This algorithm is iterative and involves forward propagation, backpropagation, and parameter updates. On the other hand, Genetic Algorithms (GA) offer advantages such as efficiency, parallelism, and global search. Normalization processing must be performed before using the BP-GA integrated optimization algorithm for data training. This is followed by selecting one feature value as the output and the remaining feature values as the input. Upon completion of training, the BP-GA integrated optimization algorithm generates prediction results.

Wavelet Neural Network (WNN) is constructed based on the wavelet transform theory, and its principle is similar to that of the Backpropagation Neural Network (BPNN). The primary characteristic of WNN is that its hidden layer neuron activation function is a wavelet basis function, which effectively utilizes the localization property of wavelet transform and the large-scale data parallel processing and self-learning capability of neural networks. Consequently, it exhibits a vital ability for approximation and achieves fast convergence speed. The specific flowchart is shown in Fig. 5.

Train and optimize stacking angle using the WNN optimization approach. Before commencing the experiment, three sets of data were randomly chosen from every amalgamation of factor levels, leading to a total of 51 data sets being extracted. WNN was employed to learn and train these 51 data sets as training sets. Subsequently, the algorithm's performance in predicting stacking angle was assessed using 17 other test sets, which can be seen in the table.

Applying WNN to predict the stacking angle response value involves predicting the dependent variable by considering the explanatory variables. Previous experiments have identified B, D, and E as the three most significant influencing factors, and this experiment employs them as explanatory variables. X1, X2, and X3 were used as input, and Y was used as the output (as shown in the topology diagram in Fig. 6). B, D, and E were represented by the numbers 1, 2, and 3, respectively. To enhance training outcomes, it is essential to normalize the training sample set in the preprocessing stage, considering the significant disparities in the magnitude of each input variable. The objective of this normalization process is to attain superior training results.

Simulation experiment and result analysis

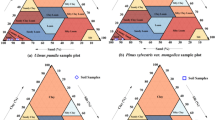

PBD screening test

Table 6 displays the design and outcomes of PBD. ANOVA analysis was conducted on outcomes applying Design Expert 8.0638, and the significance of parameters is displayed in Table 5, which reveals that factors A, B, and D exhibit a positive repercussion, indicating that stacking angle enhances as these factors enhance. Conversely, factors C, E, and F have a negative effect. The significance sequence of every factor was ascertained based on the P value of factors shown in Table 7. Three factors, E, D, and B, which have a higher significance, were selected in the steepest ascent experiment and the Box-Behnken design experiment.

Steepest climb test result analysis

Findings from the steepest ascent test are displayed in Table 8. Findings revealed that the stacking angle gradually enhanced as factors B, D, and E lessened. Furthermore, the relative error between the actual stacking and initial angles was lessened initially and then enhanced. The most minor relative error was observed in the No. 5 test. Consequently, parameter values from the No. 5 test were chosen as central points for subsequent tests. In contrast, parameter values from the No. 4 and No. 6 tests were considered low and high levels for subsequent response surface design.

RSM analysis test

The experimental plan comprises 17 test points, encompassing 12 analysis elements and 5 zero estimation errors.

Box-Behnken experiment results, shown in Table 9, indicate that three significant parameters investigated, i.e., B, D, and E. Design Expert 8.06, were applied to find a quadratic regression equation. The equation is as follows,

ANOVA results are displayed in Table 10. For fitting the mathematical model, P = 0.0003, revealing an excellent fitting degree. P value of B was less than 0.01, P values of D, E, interaction item B × D, and interaction item B × E were all less than 0.05, confirming their significance on stacking angle and validating regression. For Lack of Fit, P = 0.1529 > 0.05, revealing a tiny proportion of atypical errors in fitting betwixt obtained regression equation and actual value, with a splendid fitting degree without lack-of-fit phenomenon. The coefficient of variation CV = 1.7% indicated high validity. The coefficient of determination R2 = 0.964 and adjusted coefficient of determination R2adj = 0.918, all-surpassing 0.9, demonstrating that the proposed model precisely represents an actual situation. Additionally, Adep Precision = 14.948, demonstrating the proposed model's high precision.

According to the results in Table 11, factors that have no significant impact (D × E, B2, D2, and E2) were eliminated. ANOVA results of the modified mathematical model are displayed in Table 11. For fitting mathematical model, P < 0.001; for Lack of Fit, P = 0.1043; coefficient of variation CV = 2.08%; determination coefficient R2 = 0.915; adjusted determination coefficient R2adj = 0.877; test precision Adep Precision = 15.969. It reveals that the proposed model had a splendid fit, validity, and accuracy and had specific improvements that were in contrast with those before optimization. After optimization, the regression formula is,

Analysis of interaction effects in regression models

Analysis of interaction effects

Based on the ANOVA results of the regression model, interaction terms involving B and D and B and E had a noteworthy repercussion on stacking angle. The response surface slope's steepness further confirms the significance of these factor interactions. Moreover, the contour lines' shape indicated the strength of this interaction39. Response surface outcomes for the stacking angle of sandy soil are illustrated in Fig. 7.

When set E at 0.3, the response surface plot for the interaction between B and D is presented in Fig. 7a,b. It could be observed that the response surface curve for B was steeper contrasted to the increasing direction of D. The Contour density of B was higher than the density along the increasing direction of D, revealing that B had a crucial repercussion on the stacking angle. The contour shape appeared to be ellipsoidal, suggesting a notable interaction betwixt B and D. When D was held at a certain value, the stacking angle enhanced as B enhanced. Similarly, when set B at a specific value, the angle tended to enhance as D enhanced. Notably, when B took on an immense value, the angle showed a significant enhancement as D enhanced.

When set D at 0.5, the response surface plot for interaction between B and E is presented in Fig. 7c,d. The response surface curve for B was steeper than E's increasing direction. The Contour density of B was higher than the density along the increasing direction of E, revealing that B had a crucial repercussion on the stacking angle. The contour shape appeared to be ellipsoidal, suggesting a notable interaction betwixt B and E. When E was held at a specific value, the stacking angle enhanced as B enhanced. Similarly, when set B at a specific value, the angle tended to lessen as E enhanced. Notably, when B took on a significant value, the angle significantly lessened as E enhanced.

Comparison of machine learning models

This paper suggests conducting a comparative analysis of different machine learning algorithms to determine the most efficient fitting algorithm. Table 10 presents a comparative analysis of the non-linear algorithms. Figure 8a presents a visualization of WNN training residuals. The results demonstrate that the WNN surpasses the others in achieving lower relative errors. Besides, the BP algorithm registered a mean absolute error (MAE) of 0.28 and a root mean square error (RMSE) 0.64.

Meanwhile, the BP-GA algorithm showed improved performance with an MAE of 0.11 and an RMSE of 0.18. WNN algorithm outshone both, with the lowest recorded MAE of 0.068 and an RMSE of 0.035. Figure 8b illustrates the results of the train set, while Fig. 8c,d depict the RMSE of the training process and MAE of the training process, respectively. This outcome underscores the substantial limitations inherent in both BP and BP-GA algorithms about their precision in identifying optimal weights and thresholds. This excessive workload adversely impacts the accuracy and stability of its predictive outcomes.

This experiment has identified WNN as the most excellent optimization machine learning algorithm. Through analysis, it becomes evident that the training residual gradually decreases as the epoch progresses. However, the RMSE and MAE exhibit significant fluctuations throughout the training process.

Comparison of non-linear tools

RSM parameter optimization

Design Expert was harnessed to determine the finest values of three significant factors by solving an optimized regression equation. The optimal value of B was 0.63, D was 0.55, and E was 0.43. Median values of non-significant parameters were chosen (A was 0.4, C was 0.2, and F was 0.22). The abovementioned parameters were adopted to validate the accuracy of optimal parameter amalgamation, and other parameter configurations remained unchanged. EDEM was applied to execute simulation tests on stacking angle. The average value acquired from three repeated simulation tests was 31.75°. Its relative error from the actual value of 32.15° was 1.24%. Optimization constraints for solving it are defined as,

WNN parameter optimization

During the training process, the parameters of WNN are set as follows. The first learning rate is 0.001, the second is 0.01. The number of hidden layers is 7, and the training epochs are 100. Through WNN optimization, the stacking angle was determined to be 32.1°, exhibiting a relative error of 0.15% compared to the actual stacking angle of 32.15°. By analyzing the coordinates and conducting calculations, it was ascertained that B equaled 0.71, D equaled 0.62, and E equaled 0.41 during this instance. Through optimization utilizing BP-GA, the stacking angle achieved was 32.04°. By solely applying BP optimization, the stacking angle was measured at 31.45°. WNN demonstrates higher prediction accuracy than other non-linear tools and exhibits a more minor optimized stacking angle prediction error than other non-linear tools.

Conclusions

It is concluded that the calibration of contact parameters for sandy soil in Xinjiang provides a theoretical foundation for parameter optimization of economic crop mechanized production in Xinjiang desert areas. From the above content, details of the conclusion can be reached as follows.

This study identified the key influencing factors based on their respective P-values. Factors with a P-value of less than 0.05 were deemed to have a significant impact. According to the Plackett–Burman design for screening tests, it has been determined that the contact parameters significantly influence the stacking angle. These parameters include sandy soil-steel static friction coefficient, sandy soil-steel restitution coefficient and sandy soil-sandy soil static friction coefficient. According to ANOVA results, the interaction terms of sandy soil-sandy soil static friction coefficient and sandy soil-steel static friction coefficient and the interaction term of sandy soil-sandy soil static friction coefficient and sandy soil-steel restitution coefficient had crucial impacts. Utilize the three key factors as input and subsequently employ nonlinear tools to optimize the stacking angle data. In WNNs, the wavelet transform facilitates multi-resolution analysis, enabling the simultaneous processing of both local and global characteristics of stacking angle data. The wavelet functions possess superior time–frequency localization properties, effectively capturing the data's transient variations and local nuances. This characteristic is advantageous for analyzing nonlinear characteristics inherent in stacking angle datasets. Due to the above characteristics, WNN outperforms other nonlinear tools in the experiment. In RSM, the relative error with physical test value is 1.24%. In BP-GA, the relative error with physical test value is 0.34%. In BP, the relative error with physical test value is 2.18%. In WNN, the relative error with physical test value is 0.15%.

Nevertheless, attaining a more accurate value remains a significant challenge during the optimization process of WNN models. This challenge has also been noted in previous studies40. To mitigate computational costs, in the future, this study will enhance the evaluation metrics for machine learning algorithms and optimize WNN and integrating it with other algorithms. Additionally, the unique distribution and complexity of the dataset imply that the model and hyperparameter settings are tailored to the sample data utilized in this study. To ensure broader applicability for different kinds of datasets, additional experiments are imperative to expand the scope of the dataset in future research.

Data availability

The datasets generated and/or analysed during the current study are not publicly available due permission issues related to soil collection sites but are available from the corresponding author on reasonable request. Example from: https://www.nature.com/articles/s41559-017-0329-x.

References

Zhang, Z.-W. et al. Spatial distribution patterns and type structure of the deserts in xinjiang. Arid Zone Res. 31, 763–770 (2014).

Fang, B. W. Study on Business Model of Deserticulture in Xinjiang (Shihezi University, 2018).

Anand, A., Curtis, J. S., Wassgren, C. R., Hancock, B. C. & Ketterhagen, W. R. Experimental study of wet cohesive particles discharging from a rectangular hopper. Ind. Eng. Chem. Res. 54(16), 4545–4551 (2015).

Briend, R., Radziszewski, P. & Pasini, D. Virtual soil calibration for wheel–soil interaction simulations using the discrete-element method. Can. Aeronaut. Space J. 57(1), 59–64 (2011).

Zhang, R., Han, D., Ji, Q., He, Y. & Li, J. Calibration methods of sandy soil parameters in simulation of discrete element method. Nongye Jixie Xuebao/Trans. Chin. Soc. Agric. Mach. 48(3), 49–56 (2017).

Wu, W. J. et al. Sand modeling and parameter calibration based on DEM. J. Chin. Agric. 40(8), 182–187 (2019).

Wang, X., Hu, H., Wang, Q., Li, H. & Chen, W. Calibration method of soil contact characteristic parameters based on dem theory. Trans. Chinese Soc. Agric. Mach. 48, 79–84 (2017).

Tao, W. U. et al. Calibration of discrete element model parameters for cohesive soil considering the cohesion between particles. CABI 38, 93–98 (2017).

Lin, J. et al. Flow properties of vermicompost particle with different moisture contents. Trans. Chin. Soc. Agric. Eng. 35, 221–227 (2019).

Wang, L. M. et al. Calibration of contact parameters for pig manure based on EDEM. Trans. Chin. Soc. Agric. Eng. 36, 95–102 (2020).

Coetzee, C. J. Calibration of the discrete element method and the effect of particle shape. Powder Technol. 297, 50–70 (2016).

Pasha, M., Hare, C., Ghadiri, M., Gunadi, A. & Piccione, P. C. Effect of particle shape on flow in discrete element method simulation of a rotary batch seed coater. Powder Technol. 298, 29–36 (2016).

Liu, F., Zhang, J., Li, B. & Chen, J. Calibration of parameters of wheat required in discrete element method simulation based on repose angle of particle heap. Trans. Chin. Soc. Agric. Eng. 32(12), 247–253 (2016).

Wang, Y. X. et al. Calibration method of contact characteristic parameters for corn seeds based on EDEM. Trans. Chin. Soc. Agric. Eng. 32(22), 36–42 (2016).

Wenzheng, L. et al. Calibration of simulation parameters for potato minituber based on edem. Trans. Chin. Soc. Agric. Mach. 49, 126–142 (2018).

Khatti, J. & Grover, K. S. Prediction of uniaxial strength of rocks using relevance vector machine improved with dual kernels and metaheuristic algorithms. Rock Mech. Rock Eng. https://doi.org/10.1007/s00603-024-03849-y (2024).

Khatti, J. & Grover, K. S. Assessment of the uniaxial compressive strength of intact rocks: An extended comparison between machine and advanced machine learning models. Multiscale Multidiscip. Model. Exp. Des. https://doi.org/10.1007/s41939-024-00408-4 (2024).

Bahmed, I. T., Khatti, J. & Grover, K. S. Hybrid soft computing models for predicting unconfined compressive strength of lime stabilized soil using strength property of virgin cohesive soil. Bull. Eng. Geol. Environ. 83, 46 (2024).

Daniel, C., Khatti, J. & Graver, K. S. Assessment of compressive strength of high-performance concrete using soft computing approaches. Comput. Concret. 33, 55–75 (2024).

Khatti, J. et al. Prediction of ultimate bearing capacity of shallow foundations on cohesionless soil using hybrid LSTM and RVM approaches: An extended investigation of multicollinearity. Comput. Geotech. 165, 10912 (2024).

Khatti, J. & Grover, K. S. Estimation of intact rock uniaxial compressive strength using advanced machine learning. Transp. Infrastruct. Geotech. https://doi.org/10.1007/s40515-023-00357-4 (2023).

Khatti, J. & Grover, K. S. A scientometrics review of soil properties prediction using soft computing approaches. Arch. Comput. Methods Eng. 31, 1519–1553 (2024).

Qi, J. et al. Discrete element-based calibration of simulation parameters of Cyperus esculentus L. (tiger nut) planted in sandy soil. J. Food Process. Preserv. 7, 45 (2021).

Lin-Rong, S. et al. Establishment and parameter verification of farmland soil model in uniaxial compression based on discrete element method. Journal of China Agricultural University (2015).

DEM Zhang, H. Y. Simulation and Experimental Study on Resistance of the Sand Fixing Equipment Inserting Straws (Beijing Forestry University, 2019).

Jin, A. F., Geni, M. & Yang, Z. C. Simulation of sand cover by meshfree particle method. Eng. Mech. 27(6), 209–214 (2010).

Shuai, L., Qiaoxia, Y., Shaban, G., Longyuan, Y. & University, H. A. Parameters calibration of vermicomposting nursery substrate with discrete element method based on jkr contact model. Trans. Chin. Soc. Agric. Mach. 2, 367–377 (2018).

Zhao, Y. Z., Jiang, M. Q., Xu, P. & Zheng, J. Y. Discrete element simulation of the microscopic mechanical structure in sandpile. Acta Phys. Sin. 58(3), 421–440 (2009).

Deng, R. et al. Experimental and dem studies on the particle mixing performance in rotating drums: Effect of area ratio. Powder Technol. 314, 182–194 (2017).

Yongxiang, L. et al. Parameter calibration of wheat flour for discrete element method simulation based on particle scaling. Trans. Chin. Soc. Agric. Eng. 35(16), 320–327 (2019).

Li, J. W. et al. Calibration of parameters of interaction between clayey black soil with different moisture content and soil-engaging component in northeast China. Trans. Chin. Soc. Agric. Eng. 35(6), 130–140 (2019).

Peng, F., Wamg, H. Y., Fang, F. & Liu, Y. D. Calibration of discrete element model parameters for pellet feed based on injected section method. Trans. Chin. Soc. Agric. Eng. 49(04), 140–147 (2018).

Li, H. C., Li, Y. M., Tang, Z., Xu, L. Z. & Zhao, Z. Numerical simulation and analysis of vibration screening based on EDEM. Trans. Chin. Soc. Agric. Eng. 27(5), 117–121 (2011).

Fang, H. M. Research on the Straw-Soil-Rotary Blade Interaction Using Discrete Element Method (Nanjing Agricultural University, 2016).

Ucgul, M., Fielke, J. M. & Saunders, C. Three-dimensional discrete element modelling of tillage: Determination of a suitable contact model and parameters for a cohesionless soil. Biosyst. Eng. 121, 105–117 (2014).

Peng, C. W., Xu, D. J., He, X. & Tang, Y. H. Parameter calibration of discrete element simulation model for pig manure organic fertilizer treated with Hermetia illucen. Trans. Chin. Soc. Agric. Eng. 36(17), 212–218 (2020).

Ardestani, F., Ghaemi, A., Safdari, J. & Hemmati, A. Modeling of mass transfer coefficient using response surface methodology in a horizontal-vertical pulsed sieve-plate extraction column. Prog. Nucl. Engergy 139, 103885 (2021).

Vo, T. N. M., Nguyen, D. N. & Nguyen, V. T. Optimization of culture conditions on the proliferation of aspergillus terreus n-gl1 strain isolated from Curcuma longa L. by design-expert 6.06 and bc pharsoft software. IOP Conf. Ser. Mater. Sci. Eng. 991, 012046 (2020).

Wang, X. W., Chai, Z. & Wang, Y. L. Optimization of extraction process of polysaccharide and total saponins from Radix astragali compound additive by response surface. Feed Res. 2021, 53–58 (2021).

Do, H. Q., Aragón, A. M. & Schott, D. L. A calibration framework for discrete element model parameters using genetic algorithms. Adv. Powder Technol. 29(6), 1393–1403 (2018).

Funding

This research was funded by the local science and technology development under the guidance of the central government, grant number: kc005102, and the project of Engineering Research Center for Production Mechanization of Oasis Special Economic Crop, Ministry of Education, grant number: PMOC2021A03 and the Third Division City Financial Science and Technology Plan Project, grant number: KJ2023CG01.

Author information

Authors and Affiliations

Contributions

Conceptualization, J.Q. and L.Y.; methodology, J.Q., L.Y., C.S. and S.A.; investigation, J.Q. and S.A.; data curation, J.Q. and L.Y.; formal analysis, J.Q., L.Y. and S.A.; writing-original draft, J.Q.; writing-review and editing, J.Q., C.S., L.Y., S.A., H.M. and Z.K.; project administration, J.Q.; funding acquisition, J.Q., H.M. and Z.K.; All authors have read and agreed to the published version of the manuscript.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Qi, J., Chen, S., Yang, L. et al. Calibration of contact parameters of sandy soil for planting tiger nut based on non-linear tools. Sci Rep 14, 13895 (2024). https://doi.org/10.1038/s41598-024-64635-y

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-024-64635-y