Abstract

To improve the toughness and strength of ceramsite concrete, this study employed three different types of fibers to enhance its performance. It prepared 8 sets of specimens, conducted stress-strain curve and static strength tests, and calculated various performance parameters. Through analysis of the economic performance and failure modes, it is found that high-toughness polypropylene fibers and steel fibers significantly enhanced both the strength and toughness of ceramsite concrete, while carbon fibers, although capable of increasing strength, do not improve toughness. Specifically, high-toughness polypropylene (HTPP) fibers and steel fibers increased the strength of ceramsite concrete by 32.8% and 49.0%, respectively, resulting in corresponding improvements in strength-to-weight ratio by 33.0% and 39.8%. While the toughness index Wcu0.85 increased by 20.0% and 85.1%, respectively, Wcu0.5 increased by 29.0% and 257.6%. The failure mode exhibited ductile fracture. Additionally, HTPP fibers were more cost-effective in increasing the strength and toughness of ceramsite concrete. Finally, based on SEM test results, we explained the mechanisms through which the three types of fibers enhance the performance of ceramsite concrete from the perspective of fibers surface characteristics. These research findings provide theoretical support for the optimization design of ceramsite concrete and are of significant importance for its application as a structural material.

Similar content being viewed by others

Introduction

Ceramsite concrete possesses numerous advantages, including low weight, exceptional thermal insulation properties, notable energy efficiency, high durability, fire resistance, and cost-effectiveness, rendering it a promising green building material with significant developmental potential1. Its utilization in structures effectively reduces structural self-weight, diminishes cross-sectional dimensions, and contributes to overall structural seismic performance enhancement. Presently, ceramsite concrete finds wide-ranging application across various domains, including high-rise buildings, public structures, marine engineering, and bridge construction2,3,4,5. However, ceramsite concrete is plagued by weaknesses such as lower strength and increased brittleness. In current structural design paradigms, both compressive strength and concrete density hold pivotal roles, with material strength profoundly impacting structural design applications. Furthermore, brittleness poses potential hazards to engineering structures, particularly those subject to seismic requirements. Brittleness can facilitate crack expansion and propagation, rendering crack control and repair challenging, eventually resulting in structural damage. The brittleness of ceramsite concrete curtails its extensive application in infrastructure. While advocating for the adoption of ceramsite concrete, its lower strength and heightened brittleness often impose limitations on its use as a structural material6,7,8,9,10,11,12,13. In light of these inherent weaknesses of ceramsite concrete, numerous scholars have undertaken modification research aimed at enhancing and toughening the material, primarily through fibers addition. Currently, scholars have investigated the influence of various fibers, including polypropylene fibers, straw fibers, basalt fibers, carbon fibers, HTPP fibers, and steel fibers, on ceramsite concrete.

Xiong14 incorporated polypropylene fibers into ceramsite concrete and observed that these fibers effectively bolstered its crack resistance. Zhang15 introduced straw fibers into ceramsite concrete and noted that while they improved the material’s toughness, they might concurrently decrease its strength. Yao16 introduced basalt fibers into ceramsite concrete and found that they had a minimal impact on its strength. Zhou17 investigated the effect of carbon fibers on ceramsite concrete, revealing their capacity to enhance its strength. Similarly, Yu18 studied the influence of carbon fibers on ceramsite concrete and concluded that they could enhance its toughness. Lin and Yuan19 utilized a novel HTPP fiber in ceramsite concrete, demonstrating that HTPP fibers not only significantly enhanced its strength but also greatly improved its toughness. Regarding the impact of steel fibers on ceramsite concrete, research by Chen and Zeng20 indicated a substantial enhancement in flexural, tensile, and crack resistance strength, alongside increased energy absorption at the point of failure, resulting in a notable increase in compressive toughness. These findings were also corroborated by Mutsuddy21 and Dong Xiang22.

From the aforementioned studies, it is evident that polypropylene fibers, straw fibers, and basalt fibers do not enhance the strength of ceramsite concrete. However, carbon fibers, HTPP fibers, and steel fibers all contribute to strengthening ceramsite concrete. Additionally, each type of fiber possesses distinct characteristics. Carbon fibers offer the benefits of convenience, high elastic modulus, high strength, low density, and corrosion resistance23. HTPP fibers are recognized for their exceptional toughness, crack resistance, impact resistance, corrosion resistance, durability, ease of handling during construction, and compatibility with concrete workability24. Steel fibers imbue concrete with a certain level of ductility and offer advantages such as high tensile and shear strength, impact resistance, and good durability25. However, they also have drawbacks, including higher density and discomfort during construction due to their sharpness. Each of these three types of fibers presents unique advantages, and previous research has not extensively compared their impact on ceramsite concrete. When considering the application of ceramsite concrete in engineering projects, it is crucial to not only assess its influence on mechanical performance but also comprehensively consider factors such as construction performance and economic feasibility based on project-specific conditions. Evaluating and comparing the effects of these fibers on ceramsite concrete is essential for providing additional references for engineering applications.

This study examines the impact of carbon fibers, HTPP fibers, and steel fibers on the mechanical properties of ceramsite concrete. It investigates parameters including strength, toughness, and failure modes, and elucidates the mechanisms underlying fiber-reinforced ceramsite concrete through SEM testing. The findings of this research can provide theoretical backing for the engineering utilization of ceramsite concrete.

This study employed various techniques such as strength testing, failure mode analysis, and SEM characterization to investigate the strength characteristics and toughness properties of ceramsite concrete with different types of fibers added. Moreover, it examined the influence of fiber addition on the economic performance of ceramsite concrete, offering theoretical underpinning for its engineering application.

Experimental overview

Raw materials

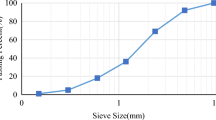

The cement utilized is manufactured by Conch Co., Ltd., with a grade of PO42.5. The sand is sourced from local sea sand in Taizhou, washed with an apparent density of 2580 kg/m3 and a fineness modulus of 2.7. The silica fume is produced by Mu Lake Admixtures Co., Ltd., with a SiO2 content exceeding 92%. Microspheres26,27,28 are manufactured by Henan Zhucheng Environmental Protection Technology Co., Ltd., with an apparent density of 2520 kg/m3 and a bulk density of 760 kg/m3. The chemical composition of the cementitious materials is shown in Table 1.The water-reducing agent employs a polycarboxylic acid water-reducing agent with a solid content of 20%.The ceramsite aggregate is made of fly ash-based ceramsite, with an apparent density of 500 kg/m³, a cylindrical compressive strength of 2.5 MPa, porosity of approximately 30%, and water absorption ranging from 10 to 20%. HTPP fibers are produced by Ningbo Shike New Materials Technology Co., Ltd., steel fibers are manufactured by Shanghai Zhenqiang Fiber Co., Ltd., and carbon fibers are produced by Shenzhen Guoheng Technology Fiber Co., Ltd. The physical and mechanical properties of the three types of fibers are shown in Table 2. The ceramsite concretes and fibers are depicted in Fig. 1.

Mix design

In this study, eight sets of ceramsite concrete specimens were designed. Group WF-0% served as the control group without any fiber additives. Considering the impact of fibers addition on economic performance, the volume addition of carbon fibers in this experiment was set at 0.6%. Among them, group PF incorporated HTPP fibers with volume fractions of 0.3%, 0.6%, and 0.9% respectively, and group SF incorporated steel fibers with volume fractions of 0.3%, 0.6%, and 0.9% respectively, while all other materials remained consistent with the Group WF-0%. The mix proportions for the eight sets of ceramsite concrete specimens are presented in Table 3.

Specimen design and fabrication

Eight sets of specimens were prepared with the following dimensions: cubic specimens measuring 100 mm×100 mm×100 mm, prismatic specimens measuring 100 mm×100 mm×300 mm, and prismatic specimens measuring 100 mm×100 mm×400 mm. The cubic specimens were used for testing compressive strength, splitting tensile strength, and electron microscopy experiments. The 100 mm×100 mm×300 mm prismatic specimens were subjected to axial compression testing, while the 100 mm×100 mm×400 mm prismatic specimens were used for flexural strength testing. Three specimens were tested for each group, and all tests were conducted at a 28-day curing age. The preparation and testing procedures of the specimens followed the GB/T 50,081 − 2019 “Standard for Test Methods of Mechanical Properties of Concrete“29.

Mechanical performance testing

In this experiment, the cube strength, splitting tensile strength, flexural strength, and axial compressive strength of ceramsite concrete were tested. The testing process followed the guidelines outlined in the “Standard for Test Methods of Physical Properties of Concrete” (GB/T 50081 − 2019)29.

-

(1)

The flexural test was conducted on specimens measuring 100 mm × 100 mm × 400 mm in size using a four-point bending test setup. The test was conducted under displacement control, with a loading rate of 0.1 mm/min.

-

(2)

The splitting tensile strength test of ceramsite concrete is conducted using the same procedure as for ordinary concrete. The testing apparatus consists of an electro-hydraulic servo pressure machine with a loading rate of 0.1 mm/min. The maximum load value (F) obtained from the splitting tensile strength test is used to calculate the splitting tensile strength (fts) of the specimen, with a precision of 0.01 MPa. The formula for calculating the splitting tensile strength is shown as Eq. (1).

In the equation, A represents the area of the fracture surface over time, measured in square millimeters (mm2), and F represents the load at failure of the specimen, measured in kilonewtons (kN).

-

(3)

When conducting stress-strain curve tests on ceramsite concrete, we employed a high-rigidity universal testing machine for precise displacement control loading, with a loading rate set at 0.12 mm/min to accommodate the high loading demands of the descending portion of the curve. Displacement gauges were strategically positioned on both sides of the specimens to accurately record vertical displacement. Additionally, longitudinal and transverse strain gauges were meticulously affixed to the midpoints of all four sides of the specimens to measure longitudinal and transverse strains. Prior to testing, preloading of the specimens was performed to ensure optimal contact between the upper and lower surfaces of the specimens and the testing machine apparatus. The test data were automatically captured using a TDS-530 static data acquisition instrument.

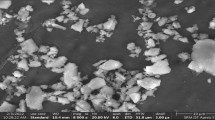

Microstructural testing

Microstructural analysis was performed using a scanning electron microscope (SEM). Following a 28-day curing period, small fragments were extracted from the center of the fractured specimens, surface-coated with gold, and observed under the SEM to examine the cement matrix, fibers surfaces, and the interface between fibers and the cement matrix.

Test results and analysis

To investigate the impact of fibers on ceramsite concrete, this study examined the effects of three different types of fibers on various properties. These properties include the stress-strain curve, compressive strength, flexural strength, splitting tensile strength, axial compressive performance, tensile-compressive ratio, flexural-compressive ratio, and toughness performance of ceramsite concrete.

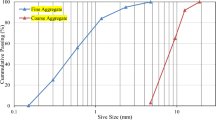

Stress-strain curve and failure mode

The complete stress-strain curves of the eight groups of ceramsite concrete are shown in Fig. 2. From Fig. 2, it can be observed that the slopes of the ascending segments of the curves are different, and the slope of the curve reflects the modulus of elasticity of each group of ceramsite concrete. The addition of different types of fibers (such as HTPP fibers or steel fibers) typically leads to changes in the slope, indicating that these fibers affect the elastic modulus of the concrete. The elastic modulus of the ceramsite concrete increases with the addition of fibers. Moreover, from the descending segments of the stress-strain curves, it can be observed that the curves for ceramsite concrete with added HTPP fibers and steel fibers exhibit a slower decline in the descending segment, and the envelope area of the stress-strain curves is significantly larger than that of the ceramsite concrete without added fibers, indicating a substantial improvement in energy absorption capacity. However, the envelope area for ceramsite concrete with added carbon fibers is almost the same as that without fibers. This suggests that the addition of HTPP fibers and steel fibers can improve the ductility of ceramsite concrete and enhance its energy absorption capacity. Additionally, the residual stress of ceramsite concrete increases significantly with the addition of HTPP fibers and steel fibers. Concrete with added steel fibers exhibits the highest residual stress, followed by concrete with added HTPP fibers. The residual stress of ceramsite concrete with added carbon fibers is similar to that of concrete without fibers. These findings indicate that adding steel fibers or HTPP fibers is highly effective in enhancing the anti-collapse capability of lightweight aggregate concrete structures.

The axial compression test failures of four types of ceramsite concrete specimens are depicted in Fig. 3. For the specimen without fibers, the failure manifests as a long crack extending upward from the bottom, with the lower edge of the concrete fragmenting and detaching, indicating a brittle failure. In the case of ceramsite concrete specimens with added carbon fibers, a long vertical crack forms in the upper-middle portion, accompanied by outward rupture on one side, highlighting a pronounced brittle failure characteristic. Conversely, specimens with HTPP fibers exhibit only a few fine short vertical cracks in the upper portion post-failure, demonstrating relatively good ductility. For specimens incorporating steel fibers, short vertical cracks form at the top upon failure, indicating favorable ductile behavior. From the perspective of axial compression failure modes, specimens without fibers display evident brittleness, the addition of carbon fibers does not improve the ductility of ceramsite concrete, while both high-toughness polypropylene fibers and steel fibers effectively enhance the brittle performance of ceramsite concrete and improve its ductility.

Strength characteristics

Cubic compressive strength

Figure 4 illustrates the compressive strength and strength growth rate of eight sets of ceramsite concrete. As depicted, when the fibers volume is added at 0.3%, 0.6%, and 0.9%, the compressive strength of ceramsite concrete with added HTPP fibers increases by 22.7%, 25.8%, and 32.8%, respectively. Similarly, the compressive strength of ceramsite concrete with added steel fibers increases by 54.0%, 42.4%, and 49.0%, respectively. Additionally, when the carbon fiber addition is 0.6%, the strength of ceramsite concret increases by 20.7%. The improvement in strength due to the fibers is much greater in ceramsite concrete than in ordinary concrete30,31.All three fibers effectively enhance the strength of ceramsite concrete, with steel fibers demonstrating the most significant effect on improving compressive strength. Moreover, the effect of HTPP fibers on strength improvement is slightly stronger than that of carbon fibers. The surface of HTPP fibers has been hydrophilically modified, which increases the friction between the fibers and the cementitious materials.

Prismatic bending strength

Flexural strength is an important performance indicator of materials, reflecting their resistance to bending. The magnitude of flexural strength is influenced by factors such as material structure, composition, processing technology, and so on. Generally, higher flexural strength indicates greater resistance to bending for the material.

In Fig. 5, it is observed that when the fibers volume addition was 0.3%, 0.6%, and 0.9% respectively, the flexural strength of the ceramsite concrete added with HTPP fibers increased by 18.4%, 23.3%, and 29.7% respectively. For ceramsite concrete added with steel fibers, the flexural strength increased by 66.1%, 70.3%, and 76.7% respectively under the same conditions. Additionally, when the addition of carbon fibers was 0.6%, the strength of the ceramsite concrete increased by 28.6%. The improvement of flexural strength in ceramsite concrete by steel fibers was most significant, while the effect of carbon fibers on flexural strength was essentially equivalent to that of HTPP fibers.

Cube splitting strength

Cube splitting tensile strength, a crucial parameter in concrete structural design, determines the material’s cracking behavior and durability. According to Fig. 6, compared to ceramsite concrete without added fibers, when the fibers volume addition is 0.3%, 0.6%, and 0.9% respectively, the splitting tensile strength of ceramsite concrete with HTPP fibers added increases by 15.8%, 20.0%, and 35.2% respectively. For ceramsite concrete with steel fibers added, the splitting tensile strength increases by 17.0%, 46.7%, and 177.0% respectively under the same conditions. However, when the addition of carbon fibers is 0.6%, the splitting tensile strength of ceramsite concrete only increases by 7.9%. Both HTPP fibers and steel fibers demonstrate the capability to enhance the splitting tensile strength of ceramsite concrete, with steel fibers exhibiting the most pronounced effect. As the addition of steel fibers increases, the growth rate of the splitting tensile strength of ceramsite concrete significantly rises. Conversely, the impact of carbon fibers on enhancing the splitting tensile strength of ceramsite concrete is minimal.

Prismatic axial compressive strength

Axial compressive strength is one of the fundamental mechanical properties of materials. As depicted in Fig. 7, compared to unreinforced ceramsite concrete, there is a slight decrease in the axial compressive strength of ceramsite concrete when the volume content of carbon fibers is 0.6%. Carbon fibers fails to enhance the axial compressive strength of ceramsite concrete. In contrast, both HTPP fibers and steel fibers effectively improve the strength of ceramsite concrete. Specifically, when the volume content of fibers is 0.3%, 0.6%, and 0.9% respectively, the axial compressive strength of ceramsite concrete added with HTPP fibers increases by 1.3%, 15.4%, and 20.5% respectively. Similarly, the axial compressive strength of ceramsite concrete added with steel fibers increases by 8.6%, 27.7%, and 13.7% respectively. Notably, there is a decrease in the axial compressive strength of the specimen with a volume content of 0.9% steel fibers compared to the specimen with a volume content of 0.6%, attributed to the discreteness of ceramsite concrete.

Performance characterization indices

Strength-to-weight ratio

The strength-to-weight ratio of materials serves as a crucial performance indicator, particularly valuable in the design and manufacturing of lightweight and high-strength structural components. Table 4 presents the dry density, strength, and strength-to-weight ratio of the eight sets of ceramsite concrete, while Fig. 8 illustrates the strength-to-weight ratio and its growth rate. Notably, the strength-to-weight ratio of each test piece of ceramsite concrete with added fibers surpasses that without added fibers, indicating the effectiveness of fibers addition in enhancing strength. Specifically, adding HTPP fibers to ceramsite concrete increases the strength-to-weight ratio by 25.4-33.0%, while adding steel fibers increases it by 35.5-46.7%. Consequently, when aiming for the same ultimate bearing capacity, incorporating fibers allows for material savings and the design of smaller cross-sectional dimensions.

Tensile-to- flexural strength ratio

The ratio of splitting tensile strength to flexural strength is commonly used to evaluate the differences in tensile performance of concrete under various loading conditions. For conventional concrete, this ratio typically ranges from 0.5 to 0.8, with a higher ratio indicating reduced disparity between tensile and flexural performance, which is advantageous for components that require consideration of tensile properties in their design. Table 5 presents the ratios of splitting tensile strength to flexural strength for eight groups of ceramsite concrete, while Fig. 9 shows the variations in the ratio and its growth rate.

Notably, the incorporation of carbon fibers significantly reduces the ratio of splitting tensile strength to flexural strength. When the carbon fiber volume content is 0.6%, the ratio decreases by up to 18%. In contrast, HTPP fibers have minimal impact on this ratio when their content is below 0.6%. However, when the HTPP fiber content exceeds 0.6%, the ratio of splitting tensile strength to flexural strength for ceramsite concrete increases with higher fiber content. Similarly, the incorporation of steel fibers causes a notable decrease in the ratio at lower fiber contents. However, at higher steel fiber contents, the ratio increases significantly. Steel fibers have a substantial effect on the ratio of splitting tensile strength to flexural strength. When the steel fiber volume content reaches 0.9%, the ratio increases by 36.26%, making ceramsite concrete with steel fibers more favorable for tensile components.

Flexural-to-compressive strength ratio

The flexural-to-compressive strength ratio is the ratio of flexural strength to compressive strength. It is a crucial performance parameter in materials engineering that can impact structural design and material selection and can be represented using Eq. (2).

Based on the experimental results of compressive strength and flexural strength of concrete in this study, the flexural-to-compressive strength ratio of the eight sets of ceramsite concrete specimens was calculated and is presented in Table 6. Additionally, the flexural-to-compressive strength ratio and its growth rate are illustrated in Fig. 10. It is evident that steel fibers have a significant effect on improving the flexural-to-compressive strength ratio of ceramsite concrete. Carbon fibers also contribute to enhancing the flexural-to-compressive strength ratio of ceramsite concrete to some extent, whereas HTPP fibers do not exhibit this improvement. This suggests that HTPP fibers are more effective in enhancing the compressive strength of ceramsite concrete than its flexural strength. Conversely, steel fibers exhibit greater effectiveness in improving the flexural strength of ceramsite concrete compared to its compressive strength.

Tensile-to-compressive strength ratio

The ratio of tensile strength to compressive strength of concrete is crucial for structural design and material selection as it impacts the overall performance and safety of structures. The ratio of tensile strength to compressive strength for each group of ceramsite concrete specimens is presented in Table 7; Fig. 11. The study revealed that the addition of HTPP fibers and carbon fibers did not improve this ratio for ceramsite concrete. These fibers exhibited a stronger effect on enhancing the compressive strength of ceramsite concrete compared to the splitting tensile strength. Additionally, when the content of steel fibers was relatively low, there was no improvement in the ratio of tensile strength to compressive strength of ceramsite concrete. However, with a volume content greater than 0.6%, the ratio significantly improved, with the growth rate of splitting tensile strength outpacing that of compressive strength.

Toughness performance

Compressive toughness index

The compressive toughness performance of ceramsite concrete can be measured using the Compressive Toughness Index Wcu0.85 and Wcu0.5, where Wcu0.85 and Wcu0.5 represent the toughness indices when the load-carrying capacity of the specimen decreases to 0.85 times and 0.5 times the peak load, respectively. Wcu0.85 is commonly used in structural ductility and energy dissipation design, while Wcu0.50 is typically employed in structural collapse resistance design, the load-displacement curves for the eight groups of ceramsite concrete specimens are shown in Fig. 12. The calculation of the Compressive Toughness Index can be referenced in the literature32,33,34,35, and the calculation procedure is illustrated in Fig. 13. The formula for calculating the Compressive Toughness Index is presented in Eqs. (3) and (4).

In the equation, F represents the axial load; h represents the height of the concrete specimen;Ωu represents the integral of the load-displacement curve when the vertical displacement is δu; δu corresponds to the vertical displacement at u times the peak load (can be taken as 0.85, 0.50, or 0.20); A is the area under compression at the specimen’s axis.

The calculation results of Wcu0.85 and Wcu0.5 are presented in Table 8. Compared to ceramsite concrete specimens without added fibers, ceramsite concrete with carbon fibers exhibited a decrease in Wcu0.85 by 18.9% and Wcu0.5 by 21.8%. Conversely, when the fibers volume fractions were 0.3%, 0.6%, and 0.9% respectively, ceramsite concrete with HTPP fibers showed an increase in Wcu0.85 by 3.2%, 11.8%, and 20.0% respectively, and Wcu0.5 increased by 16.2%, 14.3%, and 29.0% respectively. Similarly, ceramsite concrete with steel fibers experienced an increase in Wcu0.85 by 30.3%, 45.7%, and 85.1% respectively, and Wcu0.5 increased by 56.4%, 235.4%, and 257.6% respectively. Both HTPP fibers and steel fibers proved effective in enhancing the toughness of ceramsite concrete, with steel fibers exhibiting greater efficacy. However, carbon fibers did not improve the toughness of ceramsite concrete, and their addition led to a reduction in toughness.

Schematic for Compressive Toughness Calculation34.

Toughness analysis

Toughness of a material is an indicator that characterizes both the strength and ductility of the material. The magnitude of toughness is determined by the energy absorbed from the application of load until the material fails, which is represented by the area under the stress-strain curve or the load-displacement curve. It can also be expressed as the work done or energy absorbed per unit volume of the material at failure. The magnitude of toughness is related not only to the strength of the material but also to its deformation performance at failure36,37. In this study, the toughness of ceramsite concrete is calculated using the area under the stress-strain curve within a certain range. For ease of comparison, the integration region is uniformly set from 0 to 4.5. The formula for calculating toughness is shown in Eq. (5).

In the formula, \(\:\:{\text{T}}_{\text{b}}\) represents toughness (N·m), and\(\:\:\text{v}\) represents the volume of the specimen. The toughness comparison of the eight groups of specimens is shown in Fig. 14. The toughness of ceramsite concrete with added carbon fibers actually decreased, with a reduction of 9.1%. However, both HTPP fibers and steel fibers effectively enhanced the toughness of the ceramsite concrete. When the volume fraction of the fibers added was 0.3%, 0.6%, and 0.9%, the toughness of ceramsite concrete with HTPP fibers increased by 16.8%, 20.0%, and 31.3%, respectively. For ceramsite concrete with steel fibers, the toughness increased by 33.2%, 47.9%, and 47.6%, respectively.

Economic performance evaluation

Based on fiber purchase prices and market research, Table 9 provides reference prices for fibers, considering potential price fluctuations. The cost increase per cubic meter of fiber-reinforced ceramsite concrete is calculated based on the mixing ratio. Table 7 shows the cost increase for each 1 MPa improvement in ceramsite concrete strength and for each 1% improvement in toughness index, based on mechanical property test results.

It is evident from Table 10 that the cost of increasing the unit strength of ceramsite concrete using carbon fibers is the highest, at 463.6 yuan. Additionally, carbon fiber does not improve the toughness of ceramsite concrete. For HTPP fibers, when the volume fractions of HTPP fibers are 0.3%, 0.6%, and 0.9%, respectively, the price increase per 1 MPa enhancement of ceramsite concrete due to HTPP fibers is 18.1 yuan, 31.9 yuan, and 37.6 yuan, respectively. The cost increment for boosting Wcu0.85 by 1% is 3.2 yuan, 11.8 yuan, and 20.0 yuan, respectively. Similarly, for augmenting Wcu0.5 by 1%, the cost rise is 5 yuan, 11.4 yuan, and 8.4 yuan, respectively. When the volume fractions of steel fibers are 0.3%, 0.6%, and 0.9%, respectively, the price escalation per 1 MPa enhancement of ceramsite concrete due to steel fibers is 31.7 yuan, 80.7 yuan, and 104.8 yuan, respectively. The cost elevation for improving Wcu0.85 by 1% is 30.3 yuan, 45.7 yuan, and 85.1 yuan, respectively. Similarly, for enhancing Wcu0.5 by 1%, the cost increase is 6 yuan, 2.9 yuan, and 3.9 yuan, respectively. Considering the cost aspect, HTPP fibers demonstrate a price advantage in bolstering the strength and toughness of ceramsite concrete.

Mechanisms of fibers action

The interaction mechanism between fibers and cementitious materials can be quantitatively demonstrated through methods such as pull-out force to assess the bonding performance38,39, or qualitatively through SEM to observe the fiber-matrix bonding. This study primarily focuses on conducting SEM tests.The scanning electron microscope (SEM) images in Fig. 15 provide insights into the characteristics of ceramsite concrete. From Fig. 15a, it can be observed that the microstructure of the matrix and ceramsite aggregates shows a clear difference. The matrix structure is relatively dense, while the interior of the ceramsite aggregates is porous, which explains the lightweight aggregate’s water absorption characteristics and low density. At the same time, the bonding between the matrix and ceramsite aggregates is relatively strong, with no visible voids. Additionally, the interfacial transition zone between the matrix and the lightweight aggregates contains a large amount of dense hydration products, which penetrate into the ceramsite aggregates, further enhancing the bonding performance between the matrix and the lightweight aggregates. According to research in the literature40, a significant void exists at the interface between ordinary crushed stone and the cement paste matrix. Therefore, the interfacial bonding performance between the ceramsite aggregate and the matrix is superior to that of ordinary crushed stone. The weak area of ceramsite concrete is no longer the interfacial transition zone, but rather the ceramsite aggregate itself. In Fig. 15b, which shows ceramsite concrete with incorporated carbon fibers, we observe that the carbon fibers are embedded within the cement matrix but possess smooth surfaces without adhering to the cementitious material. This suggests ineffective prevention of relative sliding within the cement matrix by the carbon fibers. However, their embedding enhances the concrete’s strength, although they do not contribute to its ductility and elongation. Figure 15c and d illustrate ceramsite concrete with added HTPP fibers. Here, the surface of the HTPP fibers exhibits adhesion with cementitious material and numerous scratches, indicating strong bonding with the matrix. Under loading conditions, these fibers effectively prevent slippage and inhibit crack propagation, enhancing the concrete’s ductility and toughness. In Fig. 15e and f, depicting ceramsite concrete with added steel fibers, it observed a similar pattern of adhesion with cementitious material and the presence of scratches on the fibers surfaces. This indicates a robust bond between the steel fibers and the matrix, with the fibers effectively preventing relative slippage. Overall, both HTPP fibers and steel fibers positively impact the strength and toughness of ceramsite concrete, as evident from their SEM images.

Conclusion

This study investigated the effects of three types of fibers on the mechanical and economic performance of ceramsite concrete. The main conclusions obtained are as follows:

-

(1)

Carbon fibers can enhance the strength of ceramsite concrete but cannot improve its toughness, while steel fibers and HTPP fibers are effective in enhancing both the strength and toughness of ceramsite concrete, with steel fibers showing a greater improvement.

-

(2)

HTPP fibers exhibit better performance in enhancing the compressive strength of ceramsite concrete compared to flexural strength, while steel fibers excel in enhancing the flexural and splitting tensile strength of ceramsite concrete over compressive strength. Steel fibers have a more significant effect on improving the toughness of ceramsite concrete.

-

(3)

Ceramsite concrete without added fibers and ceramsite concrete with added carbon fibers exhibit brittle failure, while ceramsite concrete with the addition of HTPP fibers and steel fibers exhibit ductile failure.

-

(4)

Adding HTPP fibers to ceramsite concrete can increase its strength-to-weight ratio by 25.4–33.0%, while adding steel fibers can increase this ratio by 35.5–46.7%.

-

(5)

HTPP fibers offer better cost-effectiveness in enhancing both the strength and toughness of ceramsite concrete.

-

(6)

The effectiveness of HTPP fibers and steel fibers in strengthening ceramsite concrete primarily depends on their strong bond with the cementitious matrix and their ability to prevent mutual slippage.

-

(7)

This study investigated the effects of adding different fibers on the mechanical and economic performance of ceramsite concrete, providing refined decision-making guidance for engineering practice.

Data availability

The datasets used and analysed during the current study available from the corresponding author on reasonable request.

References

Xie, J. et al. Investigation of the high-temperature resistance of sludge ceramsite concrete with recycled fine aggregates and GGBS and its application in hollow blocks. J. Build. Eng. 34, 101954 (2021).

De Brito, J., Pereira, A. S. & Correia, J. R. Mechanical behaviour of non-structural concrete made with recycled ceramic aggregates. Cem. Compos. 27 (4), 429–433 (2005).

Correia, J. R., De Brito, J. & Pereira, A. S. Effects on concrete durability of using recycled ceramic aggregates. Mater. Struct. 39 (2), 169–177 (2006).

Lopez, V. et al. Eco- efficient concretes:impact of the use of white ceramic powder on the mechanical properties of concrete. Biosyst Eng. 96 (4), 559–564 (2007).

Ye, L. et al. High-strength Lightweight Aggregate Concrete Structures Behaviors, Analysis and Calculation (China Science Publishing, 2009).

JGJ /T. 12–2019.Technical Standard for Application of Lightweight Aggregate Concrete (China Architecture & Building, 2020).

Wang, Y. et al. Factors affecting brittleness behavior of coal-gangue ceramsite lightweight aggregate concrete. Front. Mater. 7, 554718 (2020).

Cui, H. Z. et al. Experimental investigation and development of analytical model for pre-peak stress-strain curve of structural lightweight aggregate concrete. Construct Build. Mater. 36, 845–859 .

Kesavamoorthi, R. & Ganesh, G. M. Impact resistance of macro and micro steel fibre reinforced self-compacted concrete (SFRSCC) with modelling and reliability analysis. Discover Appl. Sci. 6 (1), 17 (2024).

Kesavamoorthi, R. & Ganesh, G. M. Impact resistance of micro and macro crimped steel fibre reinforced self-compacting concrete with SCM. Case Stud. Const. Mater. 19, e02452 (2023).

Shah, S. M. & I, Ganesh, G. M. Micro-steel fiber-reinforced self-compacting concrete-filled steel-tube columns subjected to axial compression. Int. J. Steel Struct. 23 (4), 1031–1045 (2023).

Athiyamaan, V. & Ganesh, G. M. Analysis of the alignment of micro-steel fibers in admixture-based self-compacting concrete (MSFR-SCC) using NDT and evaluation of its effect on the modulus of rupture. Civil Eng., 10(1), (2019).

Athiyamaan, V. & Ganesh, G. M. Statistical and detailed analysis on fiber reinforced self-compacting concrete containing admixtures-A state of art of review, IOP Conference Series: Materials Science and Engineering. IOP Publishing, 263(3): 032037, (2017).

Xiong, Z. W., Li, J. Q. & Wang, Z. F. Experimental study on the compressive strength of polypropylene Fiber lightweight aggregate concrete. J. Liaon Univ. Sci. Technol. 40 (3), 237–240 (2017).

Zhang, X. Y., Lv, C. & Zhang, D. M. Toughening performance of Straw Fiber in Lightweight Aggregate concrete and predictive model for Split Tensile Strength. Mater. Rev. 34 (1), 02034–02038 (2020).

Yao, Y. et al. Influence of Basalt Fiber on the Physical and Mechanical properties of aerated Ceramsite concrete. Ann. De Chim. - Sci. Des. Matériaux. 44 (6), 427–432 (2020).

Zhou, L. Experimental study on the stress-strain curve of Carbon Fiber Reinforced concrete. Eng. Mech. 30 (7), 200–204 (2013).

Liang, Y. U. & Hua, C. Constitutive relationship of Uniaxial Compressive stress-strain for Carbon Fiber Reinforced concrete. J. Logist Eng. Coll. 29 (4), 6–12 (2013).

Lin, H. J. et al. Study on the impact of HTPP fibers on the mechanical properties of ceramsite concrete. Case Stud. Constr. Mater. 19, e02471 (2023).

Chen, Y. & Zeng, Z. X. .Strength and deformation as mechanical performance of steel Fiber light aggregate concrete. J. Huaqiao Univ. (Nat Sci). 24 (4), 380–384 (2003).

Mutsuddy, R., Bindiganavile, V. & S Lubel, A. Impact response of steel fibre reinforced lightweight concrete with crumb rubber. Proc. Annual Conf. Can. Soc. Civil Eng. 2 (4), 1434–1444 (2011).

Dong, X. & Gao, J. M. Mechanical properties of fiber-reinforced high-performance lightweight aggregate concrete. Ind. Constr., 35: 680–683. (2005).

Ren, Y. et al. The experimental study on mechanical properties of short carbon fiber concrete. J. Yunnan Agric. Univ. : Nat. Sci. 25 (5), 697–702 (2010).

Feng, S., Shi, Y. & Pham, T. M. Pullout and flexural performance of silane groups and hydrophilic groups grafted polypropylene fibre reinforced UHPC[J]. Constr. Build. Mater. 277, 122335 (2021).

Liu, Y. Study on the Mechanical Properties and Penetration Resistance Mechanism of Steel fiber Reinforced Concrete (University of Science and Technology of China, 2006).

Yuan, J. et al. A new EPS beads strengthening technology and its influences on axial compressive properties of concrete. Sci. Eng. Compos. Mater. 29, 1–15 (2022).

Yuan, J. et al. Experimental study on surface wrapping strengthening of EPS particles and its concrete performance. Sci. Eng. Compos. Mater. 29, 23–26 (2022).

Yuan, J. et al. Study on frost resistance of EPS concrete based on EPS beads wrapping modification. Constr. Build. Mater. 345 (22), 1–17 (2022).

GB/T 50081 – 2019. Standard for test Methods of Concrete Physical Andmechanical Properties (Beijing:China Architecture & Building, 2020).

Aghaee, K., Yazdi, M. A. & Tsavdaridis, K. D. Investigation into the mechanical properties of structural lightweight concrete reinforced with waste steel wires. Mag Concrete Res. 67 (4), 197–205 (2015).

Bolat, H. et al. The effects of macro synthetic fiber reinforcement use on physical and mechanical properties of concrete[J]. Compos. Part. B: Eng. 61, 191–198 (2014).

CECS13:2009. Standard for test Methods of fiber Reinforced Concrete (China Planning, 2009).

Liu, H. Experimental Study on the Seismic Performance of Low Shear Walls with High Ductility Concrete (Xi’an University of Architecture and Technology, 2016).

Hu, H. C., Liu, J. H. & Wang, J. A. Toughness testing and acoustic emission characteristics analysis of fiber-reinforced concrete. J. Coal Sci. 48 (3), 1209–1219 (2023).

Jiang, S. Y. et al. Uniaxial compressive properties and size effects of high toughness fiber reinforced concrete. Mater. Rev. 31 (12), 161–173 (2017).

Zhao, G. F. & Peng,C, S. M. K Huang.Steel fiber Reinforced Concrete structure[M] (China Architecture & Building, 1999).

Gao Langfei, Z. & Jianlan, C. Experimental study on axial compressive stress-strain curve of high-strength concrete with steel fiber. J. Fuzhou Univ. (Nat Sci. Edition). 33 (04), 501–503 (2005).

Aghaee, K. et al. Mechanism underlying effect of expansive agent and shrinkage reducing admixture on mechanical properties and fiber-matrix bonding of fiber-reinforced mortar. Cem. Concrete Res. 172, 107247 (2023).

Rocha, T. S., Cardoso, D. C. T. & BitencourtJr L a G. Macro synthetic fiber pullout behavior in short-and long-term tests. Constr. Build. Mater. 384, 131491 (2023).

Li, B. Elastoplastic Damage Constitutive Model of steel-polypropylene Hybrid fiber Reinforced Concreteand its Numerical Implementation (Wuhan University, 2006).

Funding

This research was funded by Science and technology project of Department of housing and urban–rural development of Zhejiang Province(2023K217, 2023K165, 2023K311, 2021K042), Taizhou Science and Technology Plan Project (23gyb03, 22gyb07, 22gyb11), General scientific research project of Zhejiang Education Department (Y202249335),Science and technology project of the Ministry of Housing and Urban-Rural De-velopment (2021-K-125) and Taizhou City Construction Bureau’s Project of Industry-Education Integration in Architectural Industrialization (2011026).

Author information

Authors and Affiliations

Contributions

Shifang Wang Writing - original draft, Project administration, Funding acquisition. Zeyu Li Formal analysis, Methodology, Le Fan Conceptualization, MethodologyZhicheng Zhang Data curation, Visualization Shi Yin Investigation, Resources.Ji Yuan Writing - original draft, Writing - review and editing, SupervisionHaijie He Formal analysis, Validation, SupervisionHongjian Lin Formal analysis, SupervisionWei Lin Investigation, Data curationXiongwei Dai Validation, SupervisionWen Xu Data curation, InvestigationKaisheng Yu Data curation, Investigation.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Wang, S., Li, Z., Fan, L. et al. A study on the mechanical and economic performance comparison of ceramsite concrete based on fiber selection and optimization. Sci Rep 14, 31939 (2024). https://doi.org/10.1038/s41598-024-83480-7

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-024-83480-7