Abstract

Tunnel oxide passivated contact (TOPCon) silicon solar cells are rising as a competitive photovoltaic technology, seamlessly blending high efficiency with cost-effectiveness and mass production capabilities. However, the numerous defects from the fragile silicon oxide/c-Si interface and the low field-effect passivation due to the inadequate boron in-diffusion in p-type polycrystalline silicon (poly-Si) passivated contact reduce their open-circuit voltages (VOCs), impeding their widespread application in the promising perovskite/silicon tandem solar cells (TSCs) that hold a potential to break 30% module efficiency. To address this, we have developed a highly passivated p-type TOPCon structure by optimizing the oxidation conditions, boron in-diffusion, and aluminium oxide hydrogenation, thus pronouncedly improving the implied VOC (iVOC) of symmetric samples with p-type TOPCon structures on both sides to 715 mV and the VOC of completed double-sided TOPCon bottom cells to 710 mV. Consequently, integrating with perovskite top cells, our proof of concept of 1 cm2 n-i-p perovskite/silicon TSCs exhibit VOCs exceeding 1.9 V and a high efficiency of 28.20% (certified 27.3%), which paves a way for TOPCon cells in the commercialization of future tandems.

Similar content being viewed by others

Introduction

Perovskite/silicon tandem solar cells (TSCs) have attracted considerable attention due to their advantages in efficiency and potential fabrication cost. Recent advancements have propelled this type of TSCs to achieve a record efficiency of 33.9%1. Additionally, the shared module structures with single-junction solar cells facilitate the integration of TSCs into module production without the need for additional scaffolds and wires. Silicon solar cells with the Tunnel Oxide Passivated Contact (TOPCon) structures are rising with the advantages of high power conversion efficiency (>26%)1 because it has already proven to be an upgrade from existing Passivated Emitter and Rear Contact cell production lines. These advantages make TOPCon cells, even with TOPCon structures on both sides, become a promising candidate as bottom sub-cells for perovskite/silicon TSCs.

In the pursuit of high-efficiency TSCs, texturing the front side of the silicon cell is indispensable as it could significantly reduce the refection of incident photons and extend the propagation length of photons in the absorbers2,3,4. TOPCon bottom cells contribute lower voltage in TSCs compared to mainly researched silicon heterojunction (SHJ) bottom cells, which could be ascribed to the weak passivation of the textured p-type side. The saturated current density (J0,s) of the p-type sides in TOPCon cell and SHJ cell is reported as 15.2 fA·cm−2 and 5.1 fA·cm−2, respectively5,6, which may support the correlation of lower p-type side passivation with lower voltage. Although p-type TOPCon structures on planar substrates have exhibited high passivation with implied open-circuit voltage (iVOC) over 730 mV7,8,9, the structures on textured counterparts still suffer from a lower passivation quality compared to p-type a-Si:H passivated textured sides in SHJ cells. This is primary due to the higher defect density in and/or near the ultrathin silicon oxide (SiOx) interlayer, resulting from a higher defect density on textured surface before oxidation, and the formation of degraded SiOx and boron-based clusters formed during boron in-diffusion10. The rounding etching process on the textured surface indeed reduces surface defects but simultaneously enhances reflectance9,11. Therefore, the textured surface is kept intact but an additional Si/SiOx stack was inserted to reduce boron corrosion on the SiOx/c-Si interface12. With a common alumina oxide/silicon nitride (AlOx/SiNx) capping layer, the sample showed an iVOC of 710–720 mV. Further enhancement was achieved with a multilayer hydrogenation stack, effectively suppressing defect density and acquiring an iVOC above 720 mV. However, the additional insertion and multilayer structure increase complication of production line, leading to higher costs.

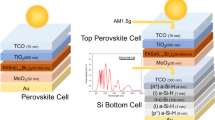

In this work, industry-compatible fabrication methods, such as ambient-pressure thermal oxidation and in situ plasma-enhanced chemical vapor deposition (PECVD), are employed to prepare highly passivated p-type TOPCon structures and double-sided TOPCon bottom cells on industrial textured wafers. The use of thermal oxidation avoids damages from ion-bombardment during the high-power plasma oxidation13,14. Different from successive thermal oxidation and poly-Si deposition in a single tool, ex situ thermal oxidation yields ultrathin SiOx layers on both wafer sides in an oxidation facility, such as a tube furnace, after which the wafers are transferred to PECVD facility to deposit intrinsic and doped silicon. The oxidation and silicon deposition processes are performed in different facilities. The mass production process technology of TOPCon structures via in situ doped amorphous silicon (a-Si) has been achieved by Feldmann et al. in 202015 and Ma et al. in 202316. Compared to widely used low pressure CVD, this in situ PECVD technique provides high versatility not only in dopant species and doses, but also in multilayer film structure. Additionally, it boasts a high SiH4 utilization rate and allows for single-side oxidation or deposition. Furthermore, this technique may avoid the damage of quartz furnaces and carriers caused by wrap-round effect17. The combination of ex-situ thermal oxidation and in situ doped a-Si is able to achieve single-side TOPCon structures. Chemical and field-effect passivation are significantly promoted through mitigating ultrathin SiOx distortion by stronger oxidation, enhancing boron in-diffusion by employing a higher thermal budget, and suppressing a higher residual defect density by strengthened hydrogenation. Consequently, the iVOC of the sample with p-type TOPCon structures on both sides exceeds 715 mV with single-side J0,s below 13 fA·cm−2, and the VOC of completed bottom cells approaches 710 mV. Employing the optimized TOPCon bottom cells, 1 cm2 n-i-p monolithic perovskite/silicon TSCs achieve high VOCs of 1.9 V and a high efficiency of 28.2% (certified 27.3%). We choose n-i-p configuration to align with single-junction silicon bottom cells featuring p–n junctions at the front side. This configuration holds promise for achieving higher efficiency and prioritizing compatibility.

Results and discussion

High passivation of p-type TOPCon structure on textured wafers

The inserted sketch in Fig. 1a illustrates the structure of the passivation sample. The wafers were textured to form sub-micrometer-sized random pyramids on both sides, which were capped by p-type poly-Si films to form p-type TOPCon structures. Firstly, ultrathin SiOx layers on both wafer sides were formed in an oxidation tool using varying process conditions, and then the wafers are transferred to a PECVD tool to deposit intrinsic and doped silicon. After the high temperature annealing under different thermal budgets, the TOPCon structures were hydrogenated by AlOx:H with increased thickness. This specific pyramid size was employed to meet the requirements of perovskite top cells.

a Effective carrier lifetime curves and (b) illumination intensity-dependent iVOC curves of control (in black) and target (in red) samples. The insert in (a) is a structure sketch of double-sided p-type TOPCon structure on textured wafers. The promotion of textured p-type TOPCon structure passivation by optimizing processes step by step: (c) extending oxidation time, (d) elevating 30 min annealing temperature, (e) extending 920 °C annealing dwell time, and (f) increasing hydrogenated AlOx thickness. The solid curves with closed symbols are for iVOC and hollow columns are for J0,s. The added values are iVOCs and corresponding J0,ss. The “N2 + O2” refers to 500 sccm N2 + 500 sccm O2.

Figure 1a, b displays the effective carrier lifetime (τeff) curves over minority carrier density and iVOC curves under different illumination intensities, respectively. The fabrication processes of the control samples include a 650 °C/5 min oxidation, 920 °C/30 min annealing, as well as a 15 nm AlOx:H hydrogenation, according to refs. 9,10,18. The control sample exhibits a τeff of 273 μs and a J0,s of 34.2 fA·cm−2 at minority carrier densities of 2 × 1015 and 5 × 1015 cm−3, respectively, together with an iVOC of 689 mV under 1 Sun illumination. This passivation is lower than that of reference published by Larionova. et al. in 201710. To provide a clear understanding of the challenges in passivating textured c-Si wafers, these processes were also performed on a double-sided planar wafer, demonstrating a significantly higher passivation with an iVOC of 716 mV, a J0,s of 5 fA·cm−2, and a τeff of 1161 μs. These results seem to be state of the art, as shown in Fig. S1 and Table S1.

The optimization of the textured p-type TOPCon structure sample can be summarized in three key aspects: varying thermal oxidation conditions for different ultrathin SiOx layers, enhancing the thermal budget in high-temperature annealing for deeper boron in-diffusion, and capping thicker AlOx:H layers for stronger hydrogenation. As depicted in Figs. 1c and S2, a strong oxidation condition results in a relatively high iVOC of 690–700 mV. On the base of enhanced oxidation condition, the thermal budget of high-temperature annealing was increased. Figures 1d, e and S3 demonstrate that a 9 min oxidation followed by a 940 °C annealing yields a high iVOC of 706 mV. Further extension of oxidation time had an inferior effect. Afterwards, in the aluminum oxide hydrogenation process, the AlOx:H layer thickness was increased up to 35 nm to facilitate strong hydrogen injection. We initially experimented with a bilayer hydrogenation stack of AlOx/SiNx but found that it had a negligible effect on improving the passivation quality. Therefore, we used a thicker AlOx:H layer to enhance passivation. As shown in Fig. 1a, b, f, after optimization the passivation level increased apparently, with an iVOC of 715 mV at 1 Sun illumination and a J0,s of 12.9 fA·cm−2 at the minority carrier density of 5 × 1015 cm−3. The τeff of 788 μs at the minority carrier density of 2 × 1015 cm−3 is also largely higher than the control one. After capping with SiNx, the iVOC further increased to 716 mV, which is tagged as the pink circle in Fig. S1. This is the state-of-art passivation level of the p-type TOPCon structure on a textured wafer based on ex situ oxidation and in situ doped a-Si. This data is higher than that from Larionova et al.10, Kale et al.19, and Mack et al9., but lower than the contact with iVOC 724 mV and J0,s 8 fA·cm−2 reported by Stodolny et al12. These textured p-type TOPCon structures were all based on thermal oxide. The possible reasons for the lower passivation of the former three contacts may be the single-layer SiNx:H hydrogenation, as well as the lack of full process optimization. In our p-type passivated contacts the p-type poly-Si layers are 30 nm thick, which are hydrogenated by single-layer AlOx:H. The higher passivation level of the later one may be ascribed to in situ low pressure thermal oxidation, poly-Si/SiOx/poly-Si/SiOx/c-Si multilayer structure and multilayer AlOx/SiNx/AlOx for hydrogenation. The insertion of additional SiOx/poly-Si leads to lower boron concentration and reduced recombination centers in c-Si, and multilayer hydrogenation injects more H into contact structure which passivates more defects at SiOx/c-Si interface.

Passivation mechanism and characteristics

Firstly, we conduct a comparison of the thicknesses and integration of ultrathin SiOx layers on planar and textured wafers. For spectroscopic ellipsometry (SE) analysis, polished wafers with (111)-orientation were used to redraw the oxide formation on the inclined plane of the textured surface. Here, we just wanted to compare the SiOx thicknesses on planar wafers and on inclined facets of textured wafers. Table S2 displays the calculated thickness of SiOx under diverse oxidation conditions, revealing a gradual increase in SiOx thickness on the (111) wafer with stronger oxidation. Though the calculated thickness may not be highly accurate, it is enough to show the trend in SiOx thickness. Furthermore, the transmission electron microscope (TEM) images in Fig. S4b–d depict that for a 5 min oxidation, the SiOx on textured surface is thinner, less uniform in thickness, and exposes silicon to metal directly at some positions. In contrast, the SiOx on the planar surface is more uniform in thickness and covers the silicon surface more completely, as shown in Fig. S4a. This observation is in accordance with previous studies20,21, suggesting that a strong oxidation process may be necessary to form a thicker SiOx layer with higher uniformity in thickness, providing enhanced protection to the textured silicon surface. The TEM image in Fig. S4f indicates that a 9 min oxidation results in a thicker SiOx layer than the 5 min oxidated case in Fig. S4c, and it more conformally segregates the wafer surface from the metal Pd. Additional morphology of the 9 min SiOx on valleys and tips can be found in Fig. S4e–g. The advantages of 9 min SiOx remain obvious in poly-Si/ SiOx/Si structures. After high-temperature annealing, the 9 min SiOx remains more uniform and consecutive than the 5 min one, as shown in Fig. 2a, b. The corresponding energy disperse spectroscopy (EDS) mappings of oxygen indicate that during annealing, oxygen diffuses into the adjacent silicon to passivate dangling bonds, and the 9 min SiOx results in a more uniform diffusion (Fig. 2c). Briefly, a 5 min SiOx interlayer becomes thinner and more discontinued and the diffused O eliminates less defects after annealing, which leaves more defects near the silicon base surface and leads to a lower passivation level with iVOC of 689 mV and J0,s of 34.2 fA·cm−2. Meanwhile, a 9 min SiOx interlayer protects the silicon base from contacting poly-Si directly after annealing, accompanied by more defects passivated by diffused O, yielding a higher iVOC of 706 mV and a lower J0,s of 18.6 fA·cm−2.

Next, we focus on the chemical state of Si in ultrathin SiOx, which was checked via X-ray photoelectronic spectroscopy (XPS) on SiOx formed directly on textured wafers. The deconvoluted Si spectra for various oxidation conditions are exhibited in Fig. 3a–c, which shows the oxidation conditions and the corresponding calculated Si4+ peak area ratios. Obviously, a higher oxidation temperature, a longer oxidation time, or a higher oxygen ratio leads to a higher Si4+ peak proportion, such as 22.7%, 32.1%, and 35.4% for 1, 5, and 9 min oxidation, respectively, meaning an increased Si4+ concentration in SiOx. Additionally, a stronger oxidation causes the Si4+ peak to shift to a higher binding energy (BE), as indicated by the arrows. This suggests that the SiOx layer is more robust after a strong oxidation. Although the SiOx interlayers will all suffer from distortion and form defects after high temperature annealing due to the stress from silicon to SiOx22,23, it can still be deduced that SiOx generated from strong oxidation exhibits superior homogeneity and a higher Si4+ content and BE. Consequently, this lends it a heightened resistance against stress, thereby reducing the likelihood of distortion and minimizing defects within the SiOx layer. This leaves fewer carrier recombination centers near the SiOx/c-Si interface and thus a higher passivation.

The influence of oxidation temperature (left column), oxidation time (middle column), and oxidation ambient (right column) on (a–c) Si chemical state in SiOx, (d–f) interface state density at SiOx/c-Si, and (g–i) boron in-diffusion profile. The “N2 + O2” in (c) refers to 500 sccm N2 + 500 sccm O2. The inserted sketch in (f) shows sample structure for C–V test. The “J0,Auger_calculated” in (g) represents Auger recombination rate calculated using in-diffusion profiles in c-Si.

Subsequently, the fixed charge density (Qf) and interface state density (Dit) of the SiOx/c-Si interface was measured and evaluated using 1 MHz capacitance-voltage (C–V) and conductance-voltage (G–V) curves for various oxidation conditions on textured wafers. The Qf and Dit were calculated using the data obtained from C–V to G–V curves with Eqs. 1 and 224,25, respectively:

where Cox is the high capacitance plateau of the oxide interlayer, Φms is the difference in metal and semiconductor working functions, Vfb is the flat band voltage, A is the area of the metal disk, q is the electron element, Gm,max is the measured highest conductance, ω is the angular frequency, and Cm is the capacitance corresponding to the measured highest conductance. The C–V curves and corresponding Dit values in terms of oxidation conditions are plotted in Fig. 3d–f. With similar Cox, the C–V curve shifts to a lower voltage position for stronger oxidation, leading to a lower Vfb and thus lower Qf of the ultrathin SiOx/AlOx stack. This suggests that stronger oxidation results in fewer defects at the SiOx/c-Si interface. The evaluated Dit values may show this trend more directly, with 3.04 × 1012 cm−2·eV−1 for 5 min oxidation (in red line) verses 2.78 × 1012 cm−2·eV−1 for 9 min oxidation (in yellow line) for example. A higher oxidation temperature or O2 ratio also yields a remarkable decrease in Dit. After high-temperature annealing, as plotted in Fig. 4a, Dit decreases significantly by an order of magnitude, and Dit of the target sample is lower than that of the control one, showing 3 × 1011 cm−2·eV−1 vs. 5.95 × 1011 cm−2·eV−1. This suggests that 9 min SiOx plus 940 °C annealing is effective in eliminating more defects on the textured c-Si surface, yielding a higher chemical passivation effect.

In addition to the analysis of the SiOx layer or SiOx/c-Si interface, one key property of the TOPCon structure is the dopant in-diffusion profile obtained by electrochemical capacitance-voltage (ECV) measurement. It shows the active dopant concentration at a specific depth, including poly-Si, SiOx interlayer, and c-Si beneath SiOx, which helps to study of the field-effect and chemical passivation. Figure 3g–i displays the doping profiles of textured samples with enhanced oxidation strength after 920 °C annealing. All of them exhibit the trend that stronger oxidation results in a lower depth of boron in-diffusion in c-Si, suggesting fewer boron dopants penetrate ultrathin SiOx. This means less damage to SiOx, benefiting chemical passivation. Moreover, the corresponding Auger recombination rates (J0,Auger_calculated) can be calculated based on profiles in c-Si below the SiOx interlayer using the EDNA2 program in PV Lighthouse26,27. The Auger recombination rate is positively related to the net dopant concentration (Ndop) and excessive carrier density (Δn)28,29. For the p-type TOPCon structure, the boron diffusion profile means active boron concentration at an increased depth in c-Si beneath the SiOx interlayer, and Auger recombination involving one electron and two holes. Therefore, the Auger rate at low injection condition in c-Si below SiOx can be worked out based on the active boron concentration at a specific depth. At high injection condition, the Auger rate in c-Si below SiOx is dominated by excessive hole density. As a result, an enhanced boron in-diffusion leads to higher boron concentration in c-Si below SiOx, and thus higher Auger rate after illumination. A shallow dopant in-diffusion may simultaneously reduce J0,Auger_calculated, improving the τeff 27. However, the low active boron concentration in c-Si beneath SiOx may allow more photo-generated electrons to reach the defect-rich SiOx/c-Si interface, accelerating carrier recombination30,31,32. At the same time, a lower boron in-diffusion depth may produce a higher contact resistivity, inhibiting the extraction of generated carriers. Therefore, annealing temperature and dwell time were increased based on strengthened oxidation to explore a balance of chemical passivation, field-effect passivation, and contact resistivity. The comparison of boron in-diffusion profiles between control and target samples can be found in Fig. 4b. With low Dit from 9 min SiOx, 940 °C annealing leads to deeper boron in-diffusion, which may provide high passivation in both chemical and field-effect aspects. Besides, the calculated J0,Auger_calculated increases only slightly by less than 0.1 fA·cm−2, having a negligible impact on passivation. Briefly, the lack of boron in-diffusion depth after 920 °C annealing forms a weaker field effect passivation, contributing to lower passivation with iVOC of 689 mV and J0,s of 34.2 fA·cm−2 for the control sample. Meanwhile, 940 °C annealing results in deeper boron in-diffusion thus a stronger field effect passivation, which may be a reason for the higher iVOC of 706 mV and the lower J0,s of 18.6 fA·cm−2 for the target sample.

It could be deduced from the evolution of p-type TOPCon structures that hydrogenation after high temperature annealing also plays a crucial role in achieving high-level passivation. Therefore, the thickness of the AlOx:H layer was increased by performing more cycle numbers during atomic layer deposition (ALD) to provide sufficient H for passivating p-type TOPCon structures on the textured surface. The cross-sectional scanning electron microscopy (SEM) images in Fig. S5 of the c-Si/SiOx/poly-Si/AlOx:H stacks confirm that a higher ALD cycle number indeed improves AlOx:H thickness to ~30 nm on the inclined facet of a pyramid. The AlOx:H layer on the valley or tip also becomes thicker. This guarantees sufficient passivation effect for different parts of the textured surface. Furthermore, as the Fourier Transform infrared spectroscopy (FTIR) data shown in Fig. 4c, the as-deposited 30 nm-thick AlOx:H layer possesses a larger O-H bond peak than the 15 nm one, and this peak collapses drastically after annealing, meaning that a large number of hydrogens are released to passivate defects33,34. Consequently, the 30 nm-thick AlOx:H layer attributes to achieve the summit passivation.

The VOC of a c-Si solar cell can be expressed by a single diode equation35,36,37,38:

where JL is the illuminated current density, J0,emitter is the saturated current density of the emitter, J0,bulk is the saturated current density in the wafer bulk, and J0,front or J0,rear is the saturated current density on the front or rear surface. It can be deduced that for a certain temperature, light absorption, c-Si substrate, and p–n junction, a high surface saturated current density, i.e., a high surface carrier recombination rate, will lead to a low VOC for a TOPCon cell. Referring to Eq. 1, we can evaluate or predict the VOC of a bottom cell to some extent. Under the assumptions that the incident light intensity, the carrier recombination rate in the wafer bulk, and the n-type TOPCon structure passivation are fixed and independent with p-type side settings, the VOC, or the whole passivation, of a bottom cell can be mainly determined by the p-type TOPCon structure passivation quality. The parameters are defined as JL = 35 mA·cm−2, J0,bulk = 10 fA·cm−2, J0,n-type contact = 5 fA·cm−2, and the test temperature is 300 K. For a p-type TOPCon structure with low passivation, the J0,p-type contact may be 40 fA·cm−2, which leads to an VOC of ~703 mV. When J0,p-type contact decreases to 15 fA·cm−2, the calculated VOC will reach ~718 mV.

Double-sided TOPCon bottom cells

An n-type TOPCon structure with high passivation and low contact resistivity on textured wafer is indispensable for a high-performance bottom cell. The structure sketch of a double-sided n-type TOPCon structure on textured wafer is inserted in Fig. 5a. To identify a suitable n-type contact, the deposition time of n-type a-Si was tuned from 80 to 400 s, followed by a 940 °C annealing and a 15 nm-thick AlOx:H hydrogenation. As displayed in Fig. 5a, b, sample with a deposition time of 320 s yields an iVOC of 737 mV and a J0,s of 5.7 fA·cm−2. With the optimized 30 nm-thick AlOx:H hydrogenation, the iVOC and J0,s of the n-type TOPCon structure passivation sample reach 746 mV and 3.4 fA·cm−2, respectively.

a The iVOC and J0,s of n-type TOPCon structures with different a-Si deposition times on industrially textured wafers. The insert is the structure sketch of double-sided n-type TOPCon structure on textured wafers. b Illumination intensity-dependent iVOC curves of 320 s n-type TOPCon structures hydrogenated by 15 nm (in black) and 30 nm (in red) AlOx:H. The corresponding passivation parameters are inserted. c The I–V curves for the target p-type (in green) and n-type (in orange) TOPCon structures for the complete bottom cell. The insert is the schematic structure of a complete n-i-p type double-sided TOPCon bottom cell with sub-micrometer-sized pyramids on the front side and industrial micrometer pyramids on the rear side, respectively. d The J–V curves and corresponding data of control and target complete bottom cells.

The low J0,s of an n-type TOPCon structure together with a highly passivated p-type TOPCon structure contribute to the high iVOC of 728 mV of the hydrogenated bottom cell. The insert in Fig. 5c depicts the structure sketch of a complete n-i-p type double-sided TOPCon bottom cell. The front side features a control or target p-type TOPCon structure on a sub-micrometer-sized pyramid textured surface, capped by a thick indium tin oxide (ITO) layer and a grid metal electrode for carrier lateral collection. The rear side incorporates an n-type TOPCon structure on a micrometer-sized pyramid textured surface, capped by a full area metal electrode. Figure 5c plots the current-voltage (I–V) curves of the optimized p- and n-type TOPCon structures measured using Cox-Strack method39. The straight curves mean that both TOPCon structures show ohmic contacts, and the p- and n-type TOPCon structures offer contact resistivities of 46 and 40 mΩ·cm2, respectively. For comparison, the contact resistivities of p- and n-type TOPCon structures for control bottom cells were also measured using the same method, which are 127 and 332 mΩ·cm2, respectively. As a result, the complete bottom cells with control and target TOPCon structures exhibit current density–voltage (J–V) curves with obvious difference, especially in VOC and fill factor (FF), as shown in Fig. 5d. The VOC of the target bottom cell reaches 706 mV and is 25 mV higher than the control one, which may result from a 25 mV difference in iVOC between the control and target p-type TOPCon structure as discussed in Fig. 1, as well as a 9 mV increase in iVOC of the n-type TOPCon structure. It should be noted that the passivation difference between hydrogenated bottom cells and complete bottom cells may be explained by the unavoidable defects induced by plasma luminescence and electron or particle bombardment during ITO sputtering40,41, increased recombination rate from the poly-Si metallization with metal42,43,44, and H escape during ITO layer and metal electrode preparation45,46,47. Additionally, the higher FF of the target bottom cell may also play a key role for increased efficiency. The lower contact resistivities of p- and n-type TOPCon structures in the target bottom cell lead to a lower series resistance of 0.6 Ω for the target bottom cell than 1 Ω for the control bottom cell, which may be the main reason for the higher FF. In summary, the optimized TOPCon structures yield both a higher VOC and a higher FF, which endows the target bottom cell with a marginally increased efficiency. The statistical data of performance parameters of complete bottom cells can be found in Fig. S6.

n-i-p monolithic perovskite/silicon TSCs

After demonstrating the effectiveness of the improvements in p-type TOPCon structures and complete Si bottom cells, we fabricated n-i-p type monolithic perovskite/silicon TSCs using the target bottom cells (See Experimental Section for more details). The schematic view and cross-sectional SEM images of the TSCs are shown in Fig. 6a. Consequently, a champion efficiency of 28.20% with an VOC of 1.90 V, a FF of 78.91% and a short-circuit current density (JSC) of 18.82 mA·cm−2 in 0.9226 cm2 aperture area was obtained for the target device in our laboratory tests (Fig. 6b) which is the top-ranking level for n-i-p type monolithic perovskite/silicon TSCs at present. For n-i-p type monolithic perovskite/silicon tandem cells, Zheng et al. and Aydin et al. reported efficiencies of 27.2% and 27.1% for ~1 cm2 tandem cells, respectively, which are the highest efficiencies for published n-i-p type monolithic perovskite/silicon tandem cells48,49. The dominating reason for our higher efficiency is the higher VOC, 1.9 V, compared to these two cells, 1.82–1.83 V. Another 1 cm2 tandem cell reported by Shen et al. shows 24.5% efficiency, which is caused by a lower VOC of 1.76 V and a JSC of 17.8 mA·cm−2 50. Therefore, our cell shows top-ranking efficiency for 1 cm2 n-i-p type monolithic perovskite/silicon TSCs. Statistics of the photovoltaic parameters imply the improved performance and reproducibility with the target bottom cells (Fig. S7). Another tandem cell was sent to Shanghai Institute of Microsystem and Information Technology (SIMIT) for authoritative certification and achieved 27.31% (25.69%) efficiencies with over 1.91 V VOCs in reverse (forward) voltage scanning directions (Fig. S8 and Table S3). The champion device from our lab measurements was not dispatched to SIMIT for calibration due to unavailability of testing schedules during that period. Regarding the comparison of results, the disparities observed in photovoltaic parameters such as VOC, JSC, FF, and PCE between our champion device in lab measurement and another device in SIMIT calibration are within the acceptable margin of <5%, which is commonly deemed satisfactory for devices sourced from different production batches. The notable variance between the two sets of testing results primarily stems from hysteresis, a phenomenon intricately linked to factors such as disparate bias scanning rates, pre-light soaking conditions, spectral distribution variations, ambient environmental disparities between the testing sites, and inherent differences in the devices themselves.

Figure 6c exhibits the external quantum efficiencies (EQEs) and the integrated currents of the champion tandem devices. 0.26 and 0.66 mA·cm−2 integrated current increases are unveiled for perovskite top cell and optimized silicon bottom cell, respectively, which is consistent with the JSC from the J–V measurements. The increased current density in the target tandem cell, as observed from the EQE results, can be primarily attributed to the highly passivated p-type TOPCon structure achieved through our optimized process. Additionally, our optimized process results in an approximately 10 mV increase in the iVOC of the rear-side n-type TOPCon structure, contributing to a slight improvement in the ~1000 nm wavelength zone of the EQE data. The current density of our tandem cell is limited by perovskite top cell, and the enhanced JSC of J–V measurements for the target tandem device is consistent with the EQE results that exhibit ~0.2 mA cm−2 improved integrated current density in the top cell. It should be noted that, the observed lower FFs in the complete bottom cell testing (73–75% for control and target cells) primarily stem from issues with the front metal gate-line. This results in lateral carrier transport loss within the ITO and p-type TOPCon structure during measurement, rather than inherent issues with the crystalline silicon bottom cell itself. However, this issue is alleviated in tandem devices, as carriers only need to recombine in the middle layer without encountering the challenges of lateral carrier transport and collection. In addition, the mismatch of current densities of top and bottom cells, which is 18.1–18.4 and 18.8–19.5 mA·cm−2 respectively according to Fig. 6c, will also lead to higher FFs51. Consequently, while the complete bottom cell may exhibit relatively poor FFs, the corresponding tandem devices demonstrate higher FFs (ranging from 76% to 79%). Furthermore, maximum power point (MPP) tracking tests were conducted to monitor the operation stability of the un-encapsulated tandem devices under ~1 sun LED illumination (Fig. S9) in a N2 flow. As shown in Fig. 6d, both types of the tandems demonstrate impressive longevities over 500 h, which indicates the commercialized potential of our tandem devices. The initial declines may originate from a “burn-in” decay often occurring in single-junction perovskite solar cells, which is related to ion migration, type of charge selective contact, and defect accumulation at the transport layer/perovskite interfaces52,53,54,55.

In this work, a highly passivated p-type TOPCon structure on randomly textured industrial wafers was achieved using industry-compatible techniques, which leads to a high efficiency of an n-i-p type monolithic perovskite/Si TSCs. The enhanced thermal oxidation condition forms more uniform ultrathin SiOx on textured silicon surface with higher Si4+ concentration and blue shift in BE, as well as lower interface state density at SiOx/c-Si. This endows SiOx with weaker distortion and lower recombination centers after high-temperature annealing, thus resulting in higher chemical passivation. The increased thermal budget of high-temperature annealing deepens boron in-diffusion, which promotes field-effect passivation soundly but Auger recombination slightly. Furthermore, a strengthened hydrogenation process was performed via increasing AlOx:H thickness, passivating more defects and leaving fewer recombination centers a step further after hydrogen injection. As the consequence, the iVOC of the p-type TOPCon structure increased to 715 mV, which is the summit passivation for the textured p-type TOPCon structure using ex-situ oxidation. Based on the optimized double-sided TOPCon bottom cell, the perovskite/Si TSCs exhibit a high VOC of 1.9 V and a remarkable efficiency of 28.2%, which is the top-ranking level for n-i-p type monolithic perovskite/silicon TSCs currently.

Methods

Preparation and characterization of passivation samples

The crystalline silicon wafers used in this study were industrial n-type Czochralski (Cz) wafers with (100) oriental. The double-side textured wafers with ~155 μm thickness, ~0.8 Ω·cm resistivity, and pyramid size below 1 μm (sub-micrometer-size) (Fig. S10a) were prepared via an industrial texturing technique in the lab. The texturing process is performed in ~70 °C potassium hydroxide-contained aqua solution for ~15 min with 8 vol.% commercial sub-micrometer pyramid texturing additives under 800 rpm stirring. Such pyramid size was chosen for the convenience of the fabrication of perovskite top cell. After standard RCA cleaning, ultrathin silicon oxide layers were prepared via thermal oxidation on both sides of the wafers. The oxidation conditions were tuned in three dimensions, i.e., temperature (550–750 °C), duration time (1–9 min), and oxygen proportion (0–100%). Then, ~40 nm-thick boron-doped a-Si (p+ a-Si) was deposited on both sides of wafers using PECVD. The chamber temperature was 220 °C; SiH4:H2:B2H6 flow ratio was 5:20:3 sccm; pressure was 0.5 Torr; plasma power and deposition time was 5 W and 160 s, respectively. Afterwards, high temperature annealing was performed to facilitate silicon crystallization as well as boron diffusion and activation, which was followed by in situ wet nitrogen hydrogenation56. The borosilicate glass (BSG) films above poly-Si were removed by dipping in diluted HF solution. Additional hydrogenation process was performed via AlOx:H deposition in an ALD system, followed by vacuum annealing in a tube furnace. The ALD camber temperature was 200 °C; the pressure was 0.03 Torr; the pulse time for Trimethylaluminium/N2/H2O/N2 is 0.15/10/0.2/10 s; the cycle number for 15 and 30 nm AlOx:H was 115 and 230, respectively. At last, the chamber was purged with N2 for 3 times. Finally, SiNx coatings were deposited on both sides of the wafer by PECVD.

The passivation properties of planar and textured samples were characterized by the iVOC, the single-side J0,s and the τeff, which were obtained by Sinton WCT-120 lifetime tester57,58,59. The former one was measured using quasi steady state (QSS) mode, and the latter two used transient mode. The contact resistivity of the optimized sample with a single-sided p-type TOPCon structure on a textured surface was measured referring the Cox-Strack method39. Active boron concentration profiles in poly-Si and c-Si were measured based on the ECV method by WEP Wafer Profiler CVP2160,61. Nano- or micro-structures of samples were observed by SEM using Hitachi Regulus 8230.

The characterizations of ultrathin SiOx layer and SiOx/c-Si interface include the thickness, integrity, and chemical state of SiOx layer, and the residual Dit of SiOx/c-Si interface. The SiOx was prepared on polished (111)-oriented wafers for SE on Woollam Complete EASE equipment, and on textured wafers for TEM observation on Talos F200X. The measurements of chemical state of SiOx and Dit of SiOx/c-Si were performed toward the structure of SiOx above textured wafers, via XPS on Axis Ultra DLD and C–V method25 on Keysight B1500A, respectively. The H content in AlOx:H film was represented by the integrated area of O-H bond peak, which was measured via FTIR on THermo NICOLET 6700.

Fabrication and test of TOPCon bottom cells

The c-Si bottom cells with double-sided TOPCon structures were prepared based on double-side textured n-type Cz (100)-oriental wafers with low bulk resistivity. These wafers were the same with those for passivation property. The bottom cell for tandem cell fabrication has a 2.5 × 2.5 cm2 wafer size and 1 × 1 cm2 work area, while the one for checking bottom cell performance has a 4 × 4 cm2 wafer size and 2.2 × 2.2 cm2 work area. Initially, SiNx protection layer was deposited on the textured surface of a single-sided industrially textured wafer (Fig. S10b), which was followed by the texturing process to form a textured surface with pyramid size below 1 μm. Then, the SiNx protection layer was removed by dipping in diluted HF solution. For the convenience of top cell fabrication, the side with a pyramid size below 1 μm was defined as the front side, while another side with industrial large pyramids was the rear side. After RCA cleaning, ultrathin silicon oxide layers were formed via thermal oxidation under optimized condition on both sides of wafers. Then, p+ a-Si and phosphorus-doped a-Si (n+ a-Si) were deposited on the front and rear side, respectively, by in situ PECVD. The deposition detail of p-type a-SiH4 was the same with the passivation samples above. For n-type a-Si:H, the chamber temperature was 220 °C; SiH4:H2:PH3 flow ratio was 5:20:6 sccm; pressure was 0.5 Torr; plasma power and deposition time was 6 W and 320 s, respectively. The following processes were high-temperature annealing, wet nitrogen hydrogenation, AlOx hydrogenation, and SiNx deposition, which were similar to symmetric passivation samples. The iVOC and τeff were measured by Sinton WCT-120 lifetime tester57,58,59. Then, SiNx/AlOx stack above the work area was removed by HF dipping. After that, ~10 nm-thick ITO was deposited on the front side as intermediate layer for the 2.5 cm wafer, but ~100 nm-thick ITO as a carrier collection layer for 4 cm wafer. The ITO film was prepared by physical vapor deposition. The passivation dropped drastically after ITO preparation, but it was recovered by forming gas annealing at 250 °C for 10 min. Afterwards, the work area on the rear side was fully covered by a ~ 100 nm-thick Ag metal electrode prepared by thermal evaporation. Here, an additional process was applied on the 4 cm wafer to form a stack of Al/Ag metal electrode with a grid and fingers above the ITO film using evaporation through a shadow mask. The passivation of the cell sample was monitored by photo-luminescence after AlOx hydrogenation and subsequent steps. The performance of the bottom cells, including VOC, JSC, FF and efficiency, was tested by a 4-wire solar cell tester consisting of a Keithley 2400 source meter and a Class AAA solar simulator produced by EnliTech Co., Ltd, which provided a light intensity of 100 mW·cm−2.

Fabrication and test of perovskite/silicon TSCs

To fabricate perovskite/silicon TSCs, a 12 nm-thick tin dioxide (SnO2) layer were deposited on the top of silicon bottom cells by a 150-cycle thermal ALD (KE-MICRO, PE ALD-F50R) with the chamber at 120 °C and Tetrakis(dimethylamino)tin(IV) (TDMASn) source at 80 °C. TDMASn/purge1/H2O/purge2 times were 0.4/5/1.5/15 s with a constant 90-sccm nitrogen flow. After UV-ozone treatment of the ALD-SnO2 layer, a SnO2 nanocrystal solution (Alfa Aesar, 15%) diluted ten times with a mixed deionized water and ethanol (1:1, vol:vol) was dynamically spin-coated on the first SnO2 layer at 5000 rpm for 35 s. Then, 150 °C-30 min post-annealing and 15 min UV-ozone treatment were conducted. A 1.7 M Cs0.05FA0.8MA0.15Pb(I0.75Br0.25)3 perovskite precursor solution, fully dissolved into a mixed solvent system comprising anhydrous dimethylformamide/dimethyl sulfoxide (4:1, vol:vol), was then spin-coated at 600/2000/8000 rpm for 6/54/15 s, and 300 μL chlorobenzene as an anti-solvent was dropped onto the center of the substrate 10 s before the end of the rotation procedure. The perovskite absorber layer was annealed at 105 °C for 15 min. A 5 mg·mL−1 phenethylammonium iodide (PEAI) in isopropanol was dynamically spin-coated on the perovskite upper surface at 5000 rpm for 35 s. 2,2′,7,7′-tetra(N,N-di-tolyl)amino-9,9-spiro-bifluorene (Spiro-TTB) doped with 2,3,5,6-tetrafluoro-7,7,8,8-tetracyanoquinodimethane (F4-TCNQ) as the hole transport layer was thermally evaporated to a 20 nm thickness with a ~ 14.3 wt.% doping ratio. For the front transparent electrode, 15 nm-thick molybdenum oxide (MoOx) and 100 nm-thick indium zinc oxide (IZO) were deposited by thermal evaporation at a 0.2 Å·s−1 rate and radio frequency sputtering under a 45 W power, respectively. Silver was evaporated through a shadow mask to a 300 nm thickness with a 1 × 1 cm2 active area. Finally, a 100 nm-thick magnesium fluoride (MgFx) was thermally evaporated as the antireflection layer.

The cross-sectional SEM images of TSCs were collected using a field-emission SEM (S-4800, Hitachi). The J–V measurements were performed through a digital source meter (Keithley 2400) and a solar simulator (94022 A, Newport) with illumination calibrated by a standard silicon cell (Bunkoukeiki, BS-520BK). The curves were achieved both in reverse (2.0 to −0.1 V) and forward (−0.1 to 2.0 V) voltage scanning modes with 200 data points. The mask for J–V measurements has a 0.9226 cm2 aperture area calibrated by SIMIT. EQE measurements were carried out through a QE system (QEX10, PV measurement, Inc). For perovskite top cell measurement, an infrared light-bias LED with 850 nm peak emission was used to saturate the silicon bottom cells, and a 0.6 V bias voltage was used to build almost short-circuit conditions. For silicon bottom cell measurement, a blue light-bias LED with a 455 nm peak emission was used to saturate the perovskite top cells and a 1 V bias voltage was applied to build an almost short circuit condition. For MPP tracking of tandems, the un-encapsulated devices operated under ~1 Sun LED illumination in a N2 flow at room temperature. The illumination intensity was calibrated to 100 mW·cm-2 with the standard silicon cell from J–V measurements.

Reporting Summary

Further information on research design is available in the Nature Research Reporting Summary linked to this article.

Data availability

All the main data are available in the main text, the Supplementary Information, and the Source Data file. All other data of this study are available from the corresponding authors on request. Source data are provided with this paper.

References

NationalRenewableEnergyLab. Best Research-Cell Efficiency Chart (https://www.nrel.gov/pv/assets/pdfs/best-research-cell-efficiencies.pdf) (2024).

Sahli, F. et al. Fully textured monolithic perovskite/silicon tandem solar cells with 25.2% power conversion efficiency. Nat. Mater. 17, 820–826 (2018).

Tockhorn, P. et al. Nano-optical designs for high-efficiency monolithic perovskite–silicon tandem solar cells. Nat. Nanotechnol. 17, 1214–1221 (2022).

Mao, L. et al. Fully textured, production-line compatible monolithic perovskite/silicon tandem solar cells approaching 29% efficiency. Adv. Mater. 34, 2206193 (2022).

Li, X. et al. Optimization of efficiency enhancement of TOPCon cells with boron selective emitter. Sol. Energy Mater. Sol. Cells 263, 112585 (2023).

Meng, F. et al. Role of the buffer at the interface of intrinsic a-Si:H and p-type a-Si:H on amorphous/crystalline silicon heterojunction solar cells. Appl. Phys. Lett. 107, 223901 (2015).

Xing, H. et al. Plasma treatment for chemical SiOx enables excellent passivation of p-type polysilicon passivating contact featuring the lowest J0 of ∼6 fA/cm2. Sol. Energy Mater. Sol. Cells 257, 112354 (2023).

Lin, N. et al. Excellent surface passivation of p-type TOPCon enabled by ozone-gas oxidation with a single-sided saturation current density of ∼4.5 fA/cm2. Sol. Energy 259, 348–355 (2023).

Mack, S. et al. Impact of surface morphology and interfacial oxide thickness on passivation quality of p+ polysilicon passivating contacts. 35th European Photovoltaic Solar Energy Conference and Exhibition 587–590 (2018).

Larionova, Y. et al. On the recombination behavior of p+-type polysilicon on oxide junctions deposited by different methods on textured and planar surfaces. Phys. Status Solidi (a) 214, 1700058 (2017).

Kale, A. S. et al. Modifications of textured silicon surface morphology and its effect on Poly-Si/SiOx contact passivation for silicon solar cells. IEEE J. Photovolt. 9, 1513–1521 (2019).

Stodolny, M. et al. Novel schemes of p+ polysi hydrogenation implemented in industrial 6” bifacial front-and-rear passivating contacts solar cells. In 35th European Photovoltaic Solar Energy Conference and Exhibition 414–417 (2018).

Guo, X. et al. Comparison of different types of interfacial oxides on hole-selective p+-poly-Si passivated contacts for high-efficiency c-Si solar cells. Sol. Energy Mater. Sol. Cells 210, 110487 (2020).

Ma, D. et al. Highly improved passivation of PECVD p-type TOPCon by suppressing plasma-oxidation ion-bombardment-induced damages. Sol. Energy 242, 1–9 (2022).

Feldmann, F. et al. Industrial TOPCon solar cells realized by a PECVD tube process. In 37th European Photovoltaic Solar Energy Conference and Exhibition 164–169 (2020).

Ma, S. et al. 24.7% industrial tunnel oxide passivated contact solar cells prepared through tube PECVD integrating with plasma-assisted oxygen oxidation and in-situ doped polysilicon. Sol. Energy Mater. Sol. Cells 257, 112396 (2023).

Lin, Y. et al. Dual-functional carbon-doped polysilicon films for passivating contact solar cells: regulating physical contacts while promoting photoelectrical properties. Energy Environ. Sci. 14, 6406–6418 (2021).

Kale, A. S. et al. Effect of silicon oxide thickness on polysilicon based passivated contacts for high-efficiency crystalline silicon solar cells. Sol. Energy Mater. Sol. Cells 185, 270–276 (2018).

Kale, A. S. et al. Tunneling or Pinholes: understanding the transport mechanisms in SiOx based passivated contacts for high-efficiency silicon solar cells. In 2018 IEEE 7th World Conference on Photovoltaic Energy Conversion (WCPEC) (A Joint Conference of 45th IEEE PVSC, 28th PVSEC & 34th EU PVSEC) 3473–3476 (2018).

Kale, A. S. et al. Effect of crystallographic orientation and nanoscale surface morphology on Poly-Si/SiOx Contacts for silicon solar cells. ACS Appl. Mater. Interfaces 11, 42021–42031 (2019).

Lozac’h, M. & Nunomura, S. Role of silicon surface, polished 〈100〉 and 〈111〉 or textured, on the efficiency of double-sided TOPCon solar cells. Prog. Photovolt. Res. Appl 28, 1001–1011 (2020).

Yang, Z. et al. Charge-carrier dynamics for silicon oxide tunneling junctions mediated by local pinholes. Cell Rep. Phys. Sci. 2, 100667 (2021).

Yan, D. et al. Silicon solar cells with passivating contacts: classification and performance. Prog. Photovolt. Res. Appl. 31, 310–326 (2023).

Dauwe, S., Schmidt, J., Metz, A. & Hezel, R. Fixed charge density in silicon nitride films on crystalline silicon surfaces under illumination. In Conference Record of the Twenty-Ninth IEEE Photovoltaic Specialists Conference, 2002, 162–165 (2002).

Hill, W. A. & Coleman, C. C. A single-frequency approximation for interface-state density determination. Solid-State Electron. 23, 987–993 (1980).

EDNA2 – PV Lighthouse (2017). https://www2.pvlighthouse.com.au/calculators/edna%202/edna%202.aspx (2023).

Stuckelberger, J. et al. Recombination analysis of phosphorus-doped nanostructured silicon oxide passivating electron contacts for silicon solar cells. IEEE J. Photovolt. 8, 389–396 (2018).

Richter, A., Glunz, S. W., Werner, F., Schmidt, J. & Cuevas, A. Improved quantitative description of Auger recombination in crystalline silicon. Phys. Rev. B 86, 165202 (2012).

Dziewior, J. & Schmid, W. Auger coefficients for highly doped and highly excited silicon. Appl. Phys. Lett. 31, 346–348 (1977).

Aberle, A. G., Glunz, S. & Warta, W. Field effect passivation of high efficiency silicon solar cells. Sol. Energy Mater. Sol. Cells 29, 175–182 (1993).

Glunz, S. W., Biro, D., Rein, S. & Warta, W. Field-effect passivation of the SiO2-Si interface. J. Appl. Phys. 86, 683–691 (1999).

Bonilla, R. S., Woodcock, F. & Wilshaw, P. R. Very low surface recombination velocity in n-type c-Si using extrinsic field effect passivation. J. Appl. Phys. 116, 054102 (2014).

Kim, Y.-C., Park, H.-H., Chun, J. S. & Lee, W.-J. Compositional and structural analysis of aluminum oxide films prepared by plasma-enhanced chemical vapor deposition. Thin Solid Films 237, 57–65 (1994).

Rai, V. R., Vandalon, V. & Agarwal, S. Surface reaction mechanisms during Ozone and Oxygen plasma assisted atomic layer deposition of aluminum oxide. Langmuir 26, 13732–13735 (2010).

Benick, J. et al. High efficiency n-type Si solar cells on Al2O3-passivated boron emitters. Appl. Phys. Lett. 92, 253504 (2008).

Mandrampazakis, A. et al. Development of Silicon-rich poly-Silicon Carbide passivating contacts for solar cells. https://resolver.tudelft.nl/uuid:5e24290b-78a8-4117-a4d2-92099083475e (2019).

Shi, D., Zeng, Y. & Shen, W. Perovskite/c-Si tandem solar cell with inverted nanopyramids: realizing high efficiency by controllable light trapping. Sci. Rep. 5, 16504 (2015).

Yang, G., Ingenito, A., Isabella, O. & Zeman, M. IBC c-Si solar cells based on ion-implanted poly-silicon passivating contacts. Sol. Energy Mater. Sol. Cells 158, 84–90 (2016).

Cox, R. H. & Strack, H. Ohmic contacts for GaAs devices. Solid-State Electron. 10, 1213–1218 (1967).

Feldmann, F. et al. High and low work function materials for passivated contacts. Energy Procedia 77, 263–270 (2015).

Demaurex, B., De Wolf, S., Descoeudres, A., Holman, Z. C. & Ballif, C. Damage at hydrogenated amorphous/crystalline silicon interfaces by indium tin oxide overlayer sputtering. Appl. Phys. Lett. 101, 171604 (2012).

Nakamura, K. et al. Interaction of metal layers with polycrystalline Si. J. Appl. Phys. 47, 1278–1283 (1976).

Mack, S. et al. Metallisation of boron-doped polysilicon layers by screen printed silver pastes. Phys. Status Solidi (RRL) – Rapid Res. Lett. 11, 1700334 (2017).

Padhamnath, P. et al. Metal contact recombination in monoPoly (TM) solar cells with screen-printed & fire-through contacts. Sol. Energy Mater. Sol. Cells 192, 109–116 (2019).

Kang, D. et al. Firing stability of polysilicon passivating contacts: the role of hydrogen. In: 2021 IEEE 48th Photovoltaic Specialists Conference (PVSC) (IEEE, 2021).

Kang, D. et al. Firing stability of phosphorus-doped polysilicon passivating contacts: factors affecting the degradation behavior. Sol. Energy Mater. Sol. Cells 234, 111407 (2022).

Kang, D. et al. Comparison of firing stability between p- and n-type polysilicon passivating contacts. Prog. Photovolt. 30, 970–980 (2022).

Zheng, J. et al. Efficient monolithic perovskite–Si tandem solar cells enabled by an ultra-thin indium tin oxide interlayer. Energy Environ. Sci. 16, 1223–1233 (2023).

Aydin, E. et al. Ligand-bridged charge extraction and enhanced quantum efficiency enable efficient n–i–p perovskite/silicon tandem solar cells. Energy Environ. Sci. 14, 4377–4390 (2021).

Shen, H. et al. In situ recombination junction between p-Si and TiO2 enables high-efficiency monolithic perovskite/Si tandem cells. Sci. Adv. 4, eaau9711 (2018).

Köhnen, E. et al. Highly efficient monolithic perovskite silicon tandem solar cells: analyzing the influence of current mismatch on device performance. Sustain. Energy Fuels 3, 1995–2005 (2019).

Christians, J. A. et al. Tailored interfaces of unencapsulated perovskite solar cells for >1000 hour operational stability. Nat. Energy 3, 68–74 (2018).

Domanski, K. et al. Migration of cations induces reversible performance losses over day/night cycling in perovskite solar cells. Energy Environ. Sci. 10, 604–613 (2017).

Hang, P. et al. Stabilizing fullerene for burn-in-free and stable Perovskite Solar cells under ultraviolet preconditioning and light soaking. Adv. Mater. 33, 2006910 (2021).

Peng, J. et al. Interface passivation using ultrathin polymer–fullerene films for high-efficiency perovskite solar cells with negligible hysteresis. Energy Environ. Sci. 10, 1792–1800 (2017).

Zhang, Z. et al. Improvement of surface passivation of tunnel oxide passivated contact structure by thermal annealing in mixture of water vapor and nitrogen environment. Sol. RRL 3, 1900105 (2019).

Sinton, R. A. & Cuevas, A. Contactless determination of current–voltage characteristics and minority‐carrier lifetimes in semiconductors from quasi‐steady‐state photoconductance data. Appl. Phys. Lett. 69, 2510–2512 (1996).

Sinton, R. A., Cuevas, A. & Stuckings, M. Quasi-steady-state photoconductance, a new method for solar cell material and device characterization. In Conference Record of the Twenty Fifth IEEE Photovoltaic Specialists Conference − 1996, 457–460 (1996).

Kane, D. E. & Swanson, R. M. Measurement of the emitter saturation current by a contactless photoconductivity decay method. In 18th IEEE Photovoltaic Specialists Conference 578–583 (1985).

Blood, P. Capacitance-voltage profiling and the characterisation of III-V semiconductors using electrolyte barriers. Semiconductor Sci. Technol. 1, 7–27 (1986).

Peiner, E., Schlachetzki, A. & Krüger, D. Doping profile analysis in Si by electrochemical capacitance‐voltage measurements. J. Electrochem. Soc. 142, 576–580 (1995).

Acknowledgements

This work was supported by the National Natural Science Foundation of China (61974178, Y.Z., U23A20354, 62025403, X.Y. and 62304201, P.H.), the Key Research and Development Program of Zhejiang Province (2021C01006, J.Y. and 2024C01055, Y.Z.), the Science and technology projects in Liaoning Province 2021 (2021JH1/10400104, Y.Z.), the Ningbo “Innovation 2025” Major Project (2022Z114, Y.Z.), the Engineering Centers with Teranergy Technology Co, Ltd. (Zhongke Yanhe) (J.Y.), the projects from Jinko Solar Co., Ltd., Canadian Solar Co., Ltd., Hainan Junda Co., Ltd., and Zhejiang Guangda Co., Ltd. (Y.Z., J.Y. and X.Y.).

Author information

Authors and Affiliations

Contributions

Z.D., C.K., X.Y., Y.Z. and J.Y. designed the experiments and supervised the project. Z.D., C.K., S.J., M.Z. and H.Z. performed the material and film preparation and characterization. Z.D., C.K., S.J., M.L. and W.L. fabricated and characterized the devices. Z.D. and Y.Z. did the numerical simulations. Z.D., C.K., Z.Y., P.H., Y.Z. and J.Y. contributed to data analysis. Z.D., C.K., P.H., Z.Y., Y.Z., X.Y. and J.Y. wrote the manuscript. All authors reviewed and contributed to the final version of the manuscript.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Peer review

Peer review information

Nature Communications thanks Guang Yang and the other, anonymous, reviewer(s) for their contribution to the peer review of this work. A peer review file is available.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Source data

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Ding, Z., Kan, C., Jiang, S. et al. Highly passivated TOPCon bottom cells for perovskite/silicon tandem solar cells. Nat Commun 15, 8453 (2024). https://doi.org/10.1038/s41467-024-52309-2

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41467-024-52309-2