Abstract

This study explores the integration of nanotechnology and Long Short-Term Memory (LSTM) machine learning algorithms to enhance the understanding and optimization of fuel spray dynamics in compression ignition (CI) engines with varying bowl geometries. The incorporation of nanotechnology, through the addition of nanoparticles to conventional fuels, improves fuel atomization, combustion efficiency, and emission control. Simultaneously, LSTM models are employed to analyze and predict the complex spray behavior under diverse operational and geometric conditions. Key parameters, including spray penetration, droplet size distribution, and evaporation rates, are modeled and validated against experimental data. The findings reveal that nanoparticle-enhanced fuels, coupled with LSTM-based predictive analytics, lead to superior combustion performance and lower pollutant formation. This interdisciplinary approach provides a robust framework for designing next-generation CI engines with improved efficiency and sustainability. Diesel engine performance and emissions were found to be influenced by variations in combustion chamber geometry, underwent validation through simulation using Diesel-RK. Re-entrant bowl profile in quaternary blend is found to exhibit 31.3% higher BTE and 8.65% lowered BSFC than the conventional HCC bowl at full load condition. Emission wise, re-entrant bowl induced 90.16% lowered CO, 59.95% lowered HC and 15.48% lowered smoke owing to improved spray penetration and faster burning of soot precursors. However, the NOx emissions of DBOPN-TRCC were found to be higher. The simulation outcomes, derived from Diesel-RK, were subsequently compared with empirical data obtained from real-world experiments. These experiments were systematically carried out under identical operating conditions, employing different piston bowl geometries.

Similar content being viewed by others

Introduction

Fuel has always been a critical driver of the global economy. Nevertheless, the huge dependence of various industries, particularly the logistics, on fossil fuel and its by-products has brought us to the edge of their depletion. This reliance raises concerns about the negative impacts, including pollution and contributions to global warming through fuel emissions. Consequently, there’s an urgent need to establish a robust framework to measure these harmful emissions. Addressing this challenge involves initiatives aimed at developing alternative fuel sources. Recent trends have witnessed a significant upsurge in Bio-fuel research due to its diverse advantages. Beyond reduced emission levels, the ease of manufacturing presents another notable benefit. Various methodologies are being utilized to improve Bio-fuel efficiency and identify the most suitable blends of fossil fuels. Predictive modeling by AI-ML (Artificial Intelligence-Machine Learning) of engine emissions plays a pivotal role in the quest for the optimal fuel blend. Predictive modeling encompasses generating outcomes through statistical methods and principles of probability. To yield accurate results, this approach necessitates specific input data. The accuracy of a prediction increases with the quantity of test data supplied to the model. The precision of a prediction is a key aspect of determining the model’s precision. Additionally, this paper delves into recent technological innovations in the realm of Machine Learning, which synergizes with AI to create a successful precise and concise model.

Ghobadian et al.1 constructed an ANN trialed model aimed at focusing on the performance and engine emissions as the output with waste vegetable cooking oil based biofuel. The experimental procedure initiated with the production of biofuel after gathering used vegetable cooking oil. This biofuel was introduced to a 2 cylinder diesel engine with emissions and performance parameters were recorded and computed. Diverse blends of biofuels were formulated, with each blend undergoing the same standardized testing protocol. This method generated a substantial volume of data utilized for training the ANN. Following the creation and evaluation of the model, the outcomes demonstrated that the back-propagation algorithm effectively predicted performance parameters. The calculated RMSE root mean error approached 0.0004, closely resembling the ideal value, indicating the accuracy of the predictions made.

Azeez et al.2 employed an enhanced artificial neural network model for estimating the carbon monoxide (CO) emissions and creating daily restricted maps of a specific area. The exhaust data used in this research originated from the traffic vehicles operating in the designated ___location. The study introduced hybrid models that integrated data mining and Geospatial Information System (GIS) with a focus on designing, analyzing, and storing various spatial data, etc. In addition, the prediction maps were generated to facilitate the analysis of localized CO emission levels. The model achieved an impressive accuracy rate of 86%, making it a valuable tool for monitoring localized emission predictions from daily traffic vehicles. This model proves highly beneficial in understanding emission patterns, especially when emissions peak, offering valuable insights into harmful emissions’ temporal trends. In 2013, a similar approach was adopted3, yielding the predictions for a turbocharged engine, encompassing both performance analysis and engine emissions. Similar ANN models were used by various researchers for predicting the performance and emission spectrums4,5,6.

Uslu et al.7 employed an ANN technique for evaluating the brake power and torque of a SI engine. The research highlighted the scarcity of information concerning the use of iso-amyl alcohol-based fuel. Test rigs were used in experiments to gather exhaust spectrum. Data sets were constructed using altering specific input data, such as throttle, speed, and adjustments in the CR (compression ratio). This dataset was further utilized to train the ANN. For the refinement of the ANN model’s performance, they utilized Response Surface Methodology (RSM). The determined correlation factor ranged from 0.94 to 0.99.

Multiple methods, including modeling and simulation, have been employed to estimate diesel engine emissions, broadly sorted for 4 categories: (1) PM and NOxsensor calibration8 ; (2) MAP (Mean average precision) -based look-up methods9 ; (3) 0 (or) 3 dimensional modeling10 ; (4) data-driven ML prediction techniques11. Radio frequency sensors were also appended by researchers to monitor the DPF (Diesel Particulate Filter), leading to enhanced DPF durability and reduced SFC12.

Nevertheless, sensor measurement techniques face challenges such as high expenses and complex structures13,14. The commonly used MAP method requires extensive calibration and significant experimental resources, particularly for obtaining precise emission characteristics during transient operations15. While modeling methods effectively reduce research time and expenses, they necessitate a deep understanding of complex theories, demanding high expertise from researchers and equipment. Among these methods, data-driven ML approaches have attracted interest owing to benefits: shorter computation time reduced cost, high predictive accuracy, and robustness16,17.

This involves using diverse machine learning algorithms to create opaque models for predicting diesel engine emissions without considering operational mechanisms18. Machine learning methods provide a balanced trade-off between model accuracy and computational resources during the modeling process, significantly simplifying the complexity of emission prediction19. Machine learning techniques have found widespread application across diverse domains, including autonomous driving19, electric vehicle charging prediction20, language processing21,22, face recognition23, and traffic flow forecasting24. Sangharatna et al.25 utilized the neural networks (NN) to diagnose faults by detecting and diagnosing engine component status through fault-related signals. Machine learning has been employed to predict diesel emissions since Atkinson26 developed a NN based prediction model in 1998. Due to the non-linear fitting and generalization capabilities of machine learning methods, they simplify efficient engine optimization16, leading to increasing interest from researchers. Table 1presents an extensive review of literature on the performance and emissions in engine characteristics (not limited to diesel engines) using ML techniques. Early studies mainly relied on data collected from lab engine operations during stable conditions, with the ANN algorithm being predominant26,27,28. Tables 2 and 3 indicate the significance of bowl geometries and nano additives in engine characteristics respectively.

The fuel spray characteristics study is also gaining prominence in recent years as it considers various key factors such that could alter the primary jet formation and atomization process48. With higher fuel density, the impinging inertia is improved drastically which could slow down the spray velocity along with higher surface tension which induces cohesive forces and larger Sauter Mean Diameter (SMD) of fuel droplets49. Some studies also reveals that, higher fuel viscosity has significant effect on hampering the aerodynamic thrust of the fuel surface and could cause much dawdle in break-up of fuel spray48. Highly viscous fuels such as B50 and above could eventually result in higher surface tension and become tough to break up on interaction with air/gas followed by higher STP, lowered SCA and increased SMD50. In general, biofuels were blended with volatile fuels to improve the spray properties51. Geng et al.52 found that pure biofuel had a 33.59% higher smoke point (STP) and a 33.08% larger droplet size (SMD) compared to diesel (B0). The addition of 30% ethanol to biodiesel resulted in a substantial decrease in its kinematic viscosity and surface tension, leading to a notable improvement in the spray breakup. Hence, the B70E30 exhibited a decrease of 22.05% in its STP and a decrease of 20.88% in its SMD, when compared to B100. Multiple studies have shown that biodiesel has ↑STP, ↓SCA, ↑SMD, and less velocity of fuel injection with respect to mineral diesel53,54. For instance, Raghu et al.55 examined spray properties of biofuels and verified that biofuels have ↑STP and ↓SCA compared to diesel55.

Novelty of the current research

In spite of several investigations delved into alternative fuel with machine learning, this particular study aims to explore quaternary fuel as the primary fuel doped with nano particle with various bowl geometries. With limited prior research delving into the combination of biofuel and nano additives, key focus of present work is to analyze the impact of introducing the nano biofuel in various bowl geometries on diesel engine behavior and performance. Apart from standard hemispherical bowl, toroidal, shallow depth and toroidal re-entrant profiles were evaluated. The gathered data underwent analysis using a machine learning approach that utilized the Long Short-Term Memory (LSTM) model within an artificial neural network framework across various engine loading conditions. Also, using Diesel-RK combustion simulation software, the fuel spray characteristics were studied for various bowl profiles and the results were compared.

Materials and methods

Test fuel preparation

The test fuel employed for the current experimentation is a quaternary blend of diesel/biodiesel/vegetable oil/pentanol and termed as DBOP blend. The DBOP blend is comprised of 50% diesel (vol%) + 5% biodiesel (vol%) + 5% vegetable oil (vol%) + 40% (vol%) pentanol. This combination is selected based on fuel properties and experimentation from previously published data56. DBOPN is prepared by blending 20ppm TiO2 nano additives with DBOP blend. TiO2 nano additives were chosen as specific additive due to its improved oxidation at higher cylinder temperatures so that it can acts as a buffer O2 for promoting oxidation. Also, the 20ppm concentration is opted based on experimentation and fuel property analysis. The blends were initially prepared using magnetic stirrer followed by ultrasonication. The blends were then checked for stability. The blends were initially found to be stable for 48 h. Then, surfactant Span80 + Tween 20 was added to the blend at concentration of 5 mg/L. After this, the blends were found to be stable for more than 120 h. The fuel properties of the test fuel blend, physio-chemical properties and properties of test fuel blends were displayed in Tables 4, 5 and 6. The above blend has been chosen owing to the fact that it has highest Brake thermal efficiency than other blend concentrations, lowered BSFC, HC, CO and Smoke opacity (indicated by Ref56). However, the NOx profile of DBOP40 is higher for which the current work employs the usage of various bowl geometries and nano additives and their influence is studied and validated by LSTM (Long Short Term Memory) machine learning algorithm.

Nanoparticle preparation and characterization

First, the precursor ingredient, titanium tetraisopropoxide, is neutralised with ethanol, hydrochloric acid, and deionised water. This was followed by thirty minutes of vigorous stirring to lower the pH of the liquid to 1.5. The pH level was then raised to six after two hours of continuous stirring and the addition of 10 mL of deionised water at room temperature. Once another titration with demonized water was completed, cladigel was produced; its pH was 8. Next, for a whole day at 150 °C, the cladigel was dried and calcined. TiO2 nanoparticles were finally produced by heating the dried samples to 300 °C for two hours. The manufactured TiO2 nanoparticles’ physical properties are described in more detail in Table 7.

Distinct lattice fringes were revealed by HR-TEM and TEM morphology (Fig. 1a, b) using the JEM-3010 ultra-high-resolution analytical electron microscope, showing the presence of nano crystalline TiO2 particles. An inconsistent spherical distribution of nano particles with mild aggregation was apparent in the SEM picture (Fig. 1c) produced using the VEGA3-TESCAN preparation. Figure 2 depicts the outcomes of the energy dispersive spectrum analysis (EDX) of TiO2 nano particles (Make: INCA Energy 250 micro analysis equipment), which verifies that the composition contains just titanium and oxygen components and does not contain any observable contamination.

(a) HR-TEM, (b) TEM, (c) SEM of TiO2nano particles57

Energy dispersive spectrum analysis (EDX) of TiO2nano particles57

Experimental setup

An agricultural based single-cylinder, four-stroke compression–ignition engine is used in this investigation. The engine configuration is depicted in Fig. 3, and the test engine’s parameters are listed in Table 8. Emission, performance, and combustion characteristics of the engine when running on a blend of DBOP enhanced with TiO2 nano additions are the primary objectives. A dynamometer is connected to the engine, and the position of the crank angle is continuously monitored by a crank angle encoder. Water cooling systems are installed in both the engine and the dynamometer. On the vertical surface of the cylinder, an in-cylinder pressure transducer is mounted in order to measure the maximum pressure. Furthermore, a system that incorporates an electronic control unit to regulate crucial engine operating parameters, such as the IT (injection timing) and IP (injection pressure). A high-speed Data Acquisition System (DAS) is utilized for the collection and recording of combustion-related data, encompassing cylinder pressure fluctuations, Heat Release Rate (HRR), and Cumulative Heat Release Rate (CHRR). The quantification of regulated emissions such as HC, CO, CO2, NOx, and smoke is conducted through AVL gas analyzers and a Bosch smoke meter.

Combustion bowl alteration

The main reason for combustion chamber geometry in the cylinder piston is to enhance the turbulence results in better mixing of air/fuel. During the first two strokes, suction of air takes place at a very high-pressure and has several motion turbulences which eventually results in a heated air. These typical erratic motions were widely dependent on bowl geometries as the movement of air is pretty random in topmost area of piston. At the end of the second stroke, only the fuel is supplied where these turbulent air mixtures uphold evaporation and vaporization phenomenon. For the present experimentation, different bowls were considered namely TCC, TRCC and SDRCC with a constant volume of 661 cc equivalent to that of standard HCC. Hence, compression ratio is also held constant. The different combustion chamber geometries were illustrated in Fig. 4.

Pictorial representations of modified piston bowl geometries58

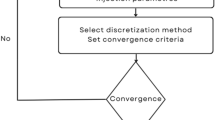

LSTM network—an overview

Time series data is a frequently encountered data format. Among the various sectors and applications that LSTM covers are finance, health monitoring, demand and supply forecasting, and other disciplines. In the context of time series analysis, a common task involves forecasting future values by utilizing historical data, typically when presented with a historical array of time series values. Time series forecasting techniques branches into two primary domains: those that rely on machine learning models and those that adhere to traditional statistic methods. While the latter recurrent neural networks (RNNs), is commonly utilized to detect, classify, and forecast anomalies in time series data.

RNNs are purposefully crafted to improve the processing of sequential data by considering the intrinsic sequential structure of the dataset. Within a conventional RNN network, the calculation proceeds sequentially from the initial sequence element to the last one, advancing one step at a time. At each step, it takes in two inputs: In the context of a basic LSTM, the input consists of current succession element and the output generated by the preceding sequence element. These inputs may be represented as numerical values or textual descriptions. The LSTM layer is usually sandwiched amid input &output layers. A deep LSTM network’s LSTM layer configuration can be altered to meet the requirements of a given application. Deep LSTM performs well over the basic LSTM due to the fact that it can process input values through time in a single LSTM cell as well as across numerous LSTM layers.

Thus, each time step’s inputs undergo a thorough processing due to the layers’ equitable distribution of the input variables. Recurrent Forecast Layer (RFL) is a subset of LSTM. To address the computational complexity issues associated with employing a conventional LSTM RNN at each time step, this novel architectural design was created. The final design (Deep LSTM with a Recurrent Projection Layer) has some LSTM layers with separate projection layers for each LSTM layer. Due to its ability to progress the model’s efficiency with greater depth, this arrangement is quite advantageous when handling excess storage demands. Increased depth also acts as a safeguard against over-fitting in models since it necessitates inputs to pass through a variety of non-linear functions in these networks.

LSTM models require intensive training by related datasets before they are suitable for use in real-world applications. Word sequences can be processed for purposes such as language modeling and text production. Linguistic models can operate effectively about multiple levels and even entire page. Also, noteworthy use pertains to processing of characters/images, where an input image undergoes analysis to create captions and sentences customized to that image. This entails the utilization of a dataset containing a multitude of images for training a specially crafted LSTM model, in conjunction with its associated descriptive captions. Following this, when new sets of images are presented to the model, it generates captions for these images. The model’s accuracy is contingent upon a range of parameters, encompassing the quantity of secreted layers, duration of training epoch and solver optimization.

LSTMs find another application akin to their role in text generation, and this pertains to the ___domain of music generation. In this scenario, LSTM networks predict musical notes by scrutinizing combinations of input notes. When it comes to language translation, LSTM’s facilitate the mapping of the sequence order of phrases from one language to its corresponding order in another language. Model training involves using a refined subset of the dataset that includes phrases and their translations after data cleaning. Before being produced as a transformed version, the input data undergoes conversion into a vector representation through an LSTM model. Generally, RNNs employ multiple layers, each encompassing functions like sigmoid, multiplication, and addition.

Within this architecture, data moves sequentially, transitioning from Ct−1till Ct, and this process involves the utilization of various parameters such as tan h, the sigma function, the value 1 (which allows data to pass through a sigmoid layer), and the value 0 (which prevents data transfer between consecutive stages). LSTM, as a subtype of recurrent neural networks, relies on long-term memory and has garnered substantial popularity across diverse fields when related with alternative models. In an ideal scenario, RNN incorporates multiple layers, each containing a 1 layer sigmoid function, multiplication, and subtraction. The math-model is displayed following the guidelines outlined in Ref59.

The LSTM architecture is shown clearly in Fig. 4. Within an LSTM, there are three gates which are controlled by the sigmoid activation function, functioning within a range from 0 to 1. In this range, a value of 0 acts as a barrier preventing incoming data, while a value of 1 allows data to pass freely. This function is purposefully crafted to generate a positive output, ensuring accurate and precise outcomes.

In the provided equations, the left-hand side (LHS) represents the input, forget, and output gates, denoted by the variables ‘i’, ‘f’, and ‘o’. The symbol sigma (σ) is used to signify the sigmoid activation function. The symbol ‘w’ stands for the weights assigned to the neurons within these respective gates. ‘At-1’ corresponds to the hidden state of the previous unit at time, ‘t-1’, while ‘St’ represents the input at the current time step. The symbol ‘b’ represents the biases linked to the three gates, as indicated in Fig. 5 with values 0, 1, 2, and 3.

Additionally, Eq. (1) delineates how the input gate determines the nature of the information to be carried forward. Equation (2) quantifies the degree to which the current unit should forget past information from the previous unit. Lastly, Eq. (3) governs the activation of the output gate for the current time step.

The variable Ct stands for the memory information at the present time step, and \({\widetilde {C}_t}\) represents the candidate for the current cell state. The symbol ‘*’ indicates element-wise multiplication of the given vectors.

Upon scrutiny of Eqs. (4)–(6), it becomes apparent that the activation function in Eq. (8) assumes a vital role in deciding what information to discard and in shaping the final output, based on the previous memory state.

LSTM comparing to other models, has layer memory, and each output rely upon prior outputs which has potential to exploit the dependencies between time series data. In engine emission prediction, LSTM will be an add-on benefit as it has gated mechanism, long term-dependency handling, versatility and lesser gradient problems.

Diesel RK—software: fuel spray visualization

Diesel-RK simulation software is a top-notch tool for optimizing parameters linked to Compression Ignition (CI) engines because it is primarily made to imitate the real-world operational scenarios of diesel engines. Estimating diesel engine performance, combustion dynamics, and emission characteristics is the primary use. It operates on both conventional diesel fuel and a wide range of biodiesel categories. In particular, Diesel-RK is able to replicate the running cycles of a number of diesel engines without much dependence on empirical coefficients. These coefficients hold constant for a wide range of engine types and operating situations. Modern models for combustion and emission production are included in the strategy, along with strategies for optimization that insure adherence to existing emission regulations. It permits optimal emission control and conforms with current regulations.

Diesel-RK is unique in that it can imitate several combustion chamber geometries, encompassing nozzle, spray placement, swirl profiles, and multiple fuel injections. It is also a beneficial tool for maximizing piston bowl shapes that comply with certain design specifications. Also, the software provides dynamic visualizations that demonstrate connections between adjacent sprays, air swirl patterns, and chamber walls and fuel sprays. A range of fuel substitutes enable an in-depth evaluation of diesel engine properties, such as thermal efficiency, in-cylinder pressure, heat release rates, ignition delays, and concentrations of soot, CO, and NOx. Therefore, by correlating these simulation results with experimental test data, exact inferences can be made. Without modifying the engine’s running conditions, Diesel-RK makes it less difficult to generate piston bowls with Hemispherical Combustion Chambers (HCC) that meet testing requirements during the experimental phase.

Multi zone-fuel spray model developed by Diesel-RK simulation58

By using default data on widely accepted technical solutions for internal combustion engines and general diesel engine knowledge, Diesel-RK streamlines the development of input data files. This simplifies the process of entering data and calibrating the engine model. It is regarded as a professional tool of the industry, which makes it indispensable for researchers working on projects with tight deadlines and sparse experimental data. It uses combustion modeling and spray evolution simulations to take use of the physical characteristics of biofuel blends. Additionally, users can designate distinct fuels for different engine running modes and preserve bespoke fuel attributes in the internal database of the software. It introduces an alternative concept known as the multi-Zone quasi-dimensional model (as shown in Fig. 6), which partitions sprays into distinct zones based on a combination of geometric principles and considerations related to mixture formation and evaporation conditions. The figure provides a comprehensive overview of the multi-zone fuel spray model, which reveals the existence of seven distinct characteristic zones that correspond to specific evaporation and combustion conditions. Before the fuel jet makes contact with the surface (jet impingement), there are only three zones in the spray:

-

1.

The free spray’s thick axial core.

-

2.

The free spray’s thick forward front.

-

3.

An outer sleeve that is diluted and encircles the free spray.

However, once the jet impinges on a nearby surface, the flow becomes more homogeneous and denser, leading to a further classification into four zones:

-

4.

An axial conical core of the near-wall flow.

-

5.

The flow’s thick core approaches the wall.

-

6.

The near-wall flow’s dense forward front.

-

7.

A diluted outer zone encircling the flow close to the wall.

Throughout its development, the spray eventually reaches both the cylinder liner and the cylinder head, completing its trajectory. Figure 7 illustrates the design of piston bowl for (a) HCC (b) SDCC, (c) TCC and d)TRCC with Diesel-RK software.

The capacity of the engine simulation program DIESEL-RK to forecast the performance, combustion dynamics, and emission features of diesel engines running on different fuels under optimal conditions has recently brought it notoriety. Using the extensive thermodynamic engine simulation program DIESEL-RK, Al-Dawody and Bhatti60 investigated creative methods for cutting NOx emissions. They recommended designing deeper piston bowls with smaller diameters based on their simulation tests, which showed a considerable reduction in nitrogen oxide emissions.

In an alternative investigation, Kuleshov61 conducted a thorough examination of diesel engine performance and emission characteristics under typical operating settings using DIESEL-RK simulation software. They found that the software may be a very useful tool for changing a lot of engine characteristics, such as fuel injection, nozzle count, exhaust gas recirculation, and piston bowl shape. Additionally, Venu et al.’s study62 looked at how emissions, combustion, and diesel engine performance are affected by the architecture of the combustion chamber. They performed engine experiments and simulations under similar operating conditions using the simulation system. With regard to the combustion chamber design, their work expands the body of knowledge regarding the software’s ability to analyze performance and optimize emissions of diesel engines.

Uncertainty analysis

Errors and uncertainties can emerge from various factors like selection and calibration of instruments, changing environment conditions, tests and observations, etc. In general, uncertainty can be grouped into two major factors, namely fixed errors and random errors. The former scenario deals with repeatability while the latter deals with the analytical measurements. In this current work, the uncertainty of measured variable (ρX) is evaluated by Guassian distribution as shown in Eq. (7) within the confidence limits of ± 2σ. 2σ is the mean limit in which the 95% of measured values rely upon.

where Xi is the number of readings, \(\overline{X} _{i}\) denotes the experimental reading and \(\sigma _{i}\) represents standard deviation. The uncertainties of calculated parameters were assessed using the expression given below:

where R in Eq. (8) represents the function of X1, X2,…Xn and X1,X2,…Xn represents number of readings taken. Hence “ρR” is computed by RMS (root mean square) of errors associated with measured parameters. The uncertainties of various measuring instruments were illustrated in Table 9. By using Eq. (9), the uncertainties in various measured parameters were evaluated and tabulated in Table 10.

Results and discussion

Performance characteristics

BSFC (brake specific fuel consumption)

The variation of BSFC for DBOPN in different combustion chamber geometries for the examined fuel samples were shown in Fig. 8. It is inferred that with increment in load, the BSFC was decreased owing to elevated cylinder temperature at peak loads thus requiring less fuel to maintain a constant speed. Among different geometries, it is found that, apart from HCC, the TCC geometry exhibits higher fuel consumption due to lacking pace in induction of swirl. At full engine load condition, the BSFC of DBOPN-TCC, DBOPN-SDCC and DBOPN-TRCC were lower than DBOPN-HCC by about 3.74%, 5.63% and 8.65% respectively. The toroidal re-entrant bowl profile boosted the engine performance due to improvements in air-fuel mixture formation and more of this mixture is being directed concerning with ignition zone and better mixing of fuel/air mixture. Overall, contemplating BTE and BSFC variation, DBOPN-TRCC is considered the best blend for improved performance.

These are on par with the findings of Jaichandar and Annamalai63 and Wickman et al.40. With toroidal re-entrant bowl geometry, the BSFC is found to increase in the literature of Lalvani et al.64. However, some contradictory results with toroidal re-entrant bowl geometry giving rise to lowered BSFC such as Mamilla et al.65, Bapu et al.66 and Venkateswaran and Nagarajan67 which is a result of abnormal fluctuation in swirl and turbulence resulting in reduced combustion efficiency and more fuel enters the combustion chamber to maintain engine speed constant giving rise to lowered BSFC profile.

BTE (brake thermal efficiency)

Figure 9illustrates the variation in Brake Thermal Efficiency (BTE) for DBOPN across various combustion chamber geometries in relation to engine load. The results highlight the crucial role of the combustion chamber in enhancing engine efficiency. In comparison to DBOPN-HCC, DBOPN-TRCC, DBOPN-SDCC, and DBOPN-TCC demonstrated higher BTE values by approximately 8.4%, 5.89% and 3.11% respectively, at full engine load conditions. This improvement is attributed to enhanced swirl and squish motion, facilitating improved air-fuel mixing with the modified chamber geometry. Notably, the TRCC bowl stands out as consistently yielding higher BTE across the entire engine load range among the various combustion chamber configurations; Brake thermal efficiency of DBOPN-TRCC is more than DBOPN-HCC and DBOP by about 8.4% and 11.97% respectively. This is because the re-entrant profile of TRCC offers fuel turbulence with an enhanced swirl. DBOPN-TRCC exhibits 33.484% BTE at 100% engine load condition with impact of fuel bound oxygen atoms in BFB improving efficiency of combustion along with higher BTE. These results are on par with the findings of Jaichandar and Annamalai63 and Venkateswaran and Nagarajan67. With toroidal re-entrant bowl geometry, the BTE is found to increase in the literatures of Mamilla et al.65, Bapu et al.66 and Venkateswaran and Nagarajan67. However, some contradictory results with toroidalre-entrant bowl geometry giving rise to lowered BTE were reported such as Lalvani et al.64.However, some contradictory results with toroidal re-entrant bowl geometry giving rise to lowered BTE due to abnormal fluctuation in swirl and turbulence resulting in reduced combustion efficiency followed by lowered BTE profile as reported such as Lalvani et al.64.

Emission characteristics

Carbon monoxide (CO)

The CO emission fluctuation for DBOPN in different piston bowl geometries with engine load is delineated in Fig. 10. From the figure, it is found that D100 emits more CO when compared to oxygenated additives since it has less built-in O2and can convert more easily into CO2 during oxidation. All other geometries show lower CO emissions when compared to DBOPN-HCC. The CO emissions of DBOPN-TCC, DBOPN-SDCC, and DBOPN-TRCC are, at 100% engine load, approximately 48.85%, 5.96%, and 90.16% lower than those of DBOPN-HCC. The O2 present in BBOPN mixes, which may have increased CO oxidation and thus reduced CO emission, and improved air circulation within the combustion chamber are responsible for this enormous reduction in CO emissions. Maximum CO reduction is evident for DBOPN-TCC and DBOPN-TRCC due to potential utilization of inbuilt O2, quick fuel molecule breaking and swirl improvement along with squish formation which causes the fuel to be directly concerned with the combustion chamber. Overall, DBOPN-TRCC results in reduced CO emission throughout the load. Reduced CO emission with such a re-entrant profile is confirmed with the results revealed by Wickman et al.40 and Venkateswaran and Nagarajan67. With toroidal re-entrant bowl geometry, CO is found to increase in the literature of Benajes et al.68. However, some contradictory results with toroidal re-entrant bowl geometry giving rise to lowered CO were reported such as Mamilla et al.65, Li et al.20, Jaichandar and Annamalai63, Dolak et al.69, Lalvani et al.64 and Venkateswaran and Nagarajan67 which could be attributed to poor utilisation of inbuilt O2, difficulty in fuel molecule breaking and poor swirl development which causes the fuel to be poorly oxidized and reduced CO levels.

HC (hydrocarbon)

Figure 11 portrays the fluctuation of HC emission for DBOPN in different piston bowl geometries with engine loads. The deduction is that the alteration of the combustion chamber can significantly contribute to the reduction of Hydrocarbon (HC) emissions. HC emissions are highest for D100, while the lowest HC is reported for DBOPN-TRCC throughout the engine load condition. At 100% load, DBOPN-TRCC exhibits HC emission of about 0.02 g/kWh which is lower than DBOPN-HCC, DBOPN-TCC and DBOPN-SDCC by about 59.95%, 57.78% and 41.63% respectively. TRCC bowl supports the turbulent kinetic energy of the fuel mixture and therefore channels to the combustion zone. This occurrence, therefore, lowers the possibility of formation of fuel-rich zones followed by HC emission reduction. Even though DBOPN-TCC is comparatively lesser HC than DBOPN-HCC, the quantum of emissions is higher than other chambers such as SDRCC and TRCC which could be possibly attributed to TCC due to absence of re-entrant geometry causes wall wetting tendency followed by higher HC emission. The reduced Hydrocarbon (HC) emissions, particularly evident with the TRCC geometry, align closely with the research findings of Jaichandar et al.70 and Wickman et al.40. With toroidal re-entrant bowl geometry, the HC emissions are found to increase in the literatures of Benajies et al.68. However, some contradictory results with toroidal re-entrant bowl geometry giving rise to lowered HC emissions were reported such as Mamilla et al.65, Lalvani et al.64 and Venkateswaran and Nagarajan67 as a result of lowered rich mixture zones in crevice areas of the combustion chamber due to the presence of swirl in combustion chamber.

NOx (oxides of nitrogen)

NOx fluctuation for DBOPN with relation to engine load is shown in Fig. 12 for various combustion chamber designs. D100 is the mix that shows the least amount of NOx when the engine is running. At engine loads of 25%, 50%, 75%, and 100%, respectively, the NOx emissions of DBOPN-HCC were approximately 45.8%, 57.43%, 47.46%, and 57.18% higher than those of D100. When using a DBOPN mix, all of the four bowl geometries—TCC, SDRCC, and TRCC—show greater NOx levels than HCC. At 100% load, the NOx liberated by DBOPN-TCC, DBOPN-SDRCC and DBOPN-TRCC were about 17.56 g/kWh, 18.03 g/kWh and 18.81 g/kWh respectively, while DBOPN-HCC emits only 17.09 g/kWh. Consequently, the DBOPN-TCC configuration achieved the lowest NOx emissions due to reduced swirl and squish fuel motion. This directs the fuel spray away from the combustion zone, thereby lowering the adiabatic temperature and resulting in reduced NOx emissions. Higher NOx emissions of DBOPN-TRCC are merely compensated for improved BTE and the lowered CO, HC emissions with respect to other geometries. Higher NOxemissions with TRCC are reported by few researchers65,70.

While some contradiction results with lowered NOx with TRCC is also reported by Wei et al.71, Prasad et al.72 and Wickman et al.40. With toroidal re-entrant bowl geometry, the NOx emissions are found to increase in the literatures of Mamilla et al.65, Jaichandar and Annamalai63,70, Li et al.20, Lalvani et al.64 and Venkateswaran and Nagarajan67. However, some contradictory results with toroidal re-entrant bowl geometry giving rise to lowered NOx emissions were reported such as Wickman et al.40, Lim and Min73 and Wei et al.71. This can be attributed to a reduction in swirl and squish fuel motion, directing the fuel spray away from the combustion zone, thereby reduced adiabatic temperature and poor O2utilization lowering the NOx emission subsequently.

Smoke opacity

The fluctuation smoke opacity for DBOPN in various combustion chamber designs in relation to engine load is shown in Fig. 13. As most of the literature points out, it can be seen as a trade-off feature between smoke opacity and NOx emissions. For D100, the maximum smoke opacity is seen at all engine load conditions. When comparing DBOPN-TCC, DBOPN-SDCC, and DBOPN-TRCC to DBOPN-HCC, the smoke opacity of each is approximately 2.71%, 3.58%, and 15.48% lower, respectively, at 100% engine load. This can be attributed to the various bowl shapes that provide efficient spray penetration, enhanced evaporation, and rapid precursor burning, all of which reduce the likelihood of undesired fuel accumulation and the air shortfall in the combustion zone, giving rise to lowered smoke emissions. DBOPN-TRCC achieved highest smoke reduction throughout the load could be attributed to enhanced fuel swirl thereby lessening the soot precursor formation, improved oxidation followed by lowered smoke. Lowered smoke capacity with the usage of re-entrant bowl profile was on par with similar research findings of Wei et al.71. Results with toroidal re-entrant bowl geometry giving rise to lowered smoke emissions were reported such as Mamilla et al.65, Jaichandar and Annamalai63,70, Lalvani et al.64 and Venkateswaran and Nagarajan67 and Dolak et al.69.

LSTM algorithm prediction

The results have been included into the LSTM network to examine how various fuel mixes operate and what kind of emissions they produce under full engine load (80–100%) condition. To validate the model, the collected data is used for training and subsequently compared to the values generated by the LSTM network. For most parameters, a second-order function was applied to ensure consistency, and the dataset was constructed to encompass Brake Thermal Efficiency (BTE), Brake Specific Fuel Consumption (BSFC) and the concentrations of Carbon Dioxide (CO2), Carbon Monoxide (CO), Nitrogen Oxides (NOx), and smoke opacity. Table 11 presents the regression model coefficients (P, Q, R, S) associated with various parameters (BTE, BSFC, HC, CO, NOx and smoke opacity). In each case, coefficient P holds no significance. These regression coefficients are employed to prepare and subsequently train the dataset in conjunction with LSTM. Figures 14 and 15 have been included to depict the comparison of regression models with Long Short-Term Memory (LSTM) specifically for Brake Thermal Efficiency (BTE) and Hydrocarbon emissions (HC). Similarly, this methodology can be extended to predict various parameters. Table 12 displays the Root Mean Square Error (RMSE) values for the LSTM model concerning different parameters for the test fuels. Upon the obtained predicted data, LSTM could act as an effective tool for the present state of art problems. Also, LSTM can be effectively implemented in optimizing the sourced data from the diesel engine with lesser RMSE values.

Diesel RK—fuel spray visualization

The DBOP blend is a blend consisting of diesel/Jatropha biodiesel, vegetable oil and pentanol with different concentrations. To enhance its properties, it has been enriched with alumina nano additives at a concentration of 20 parts per million (ppm). The resulting fuel is referred to as DBOPN. Subsequently, the properties of HPF are utilized as inputs, which run over identical working environment to those of a typical diesel engine. The software analyzes the performance of the engine using different combustion chamber geometries, including HCC (Homogeneous Charge Compression), SDRCC (Swirl Direct Re-Entrant Combustion Chamber), TCC (Turbulence Charge Compression), and TRCC (Toroidal Re-Entrant Combustion Chamber). The simulation within Diesel-RK focuses on fuel spray occurrence and combustion phenomenon within the various bowl profiles, as illustrated in Fig. 16. Among these geometries, the TRCC design stands out as the most effective in terms of enhancing performance and optimizing combustion parameters. This superiority is attributed to the TRCC’s ability to generate a potent squish effect along with efficient air movement, resulting in improved air-fuel interaction.

The outcomes derived from the Diesel-RK simulation are compared with actual experimental data obtained under identical operating conditions. The comparison involves the utilization of DBOPN blend and various bowl strategies. Table 13 presents the comparative analysis of these results. It is evident that the TRCC geometry consistently outperforms the other combustion chamber designs in several key aspects, including BTE, BSFC, higher Pcyl, and an increased HRR. This excellence is mainly credited to the generated squish effect and swirled air movement within the TRCC design, which significantly contributes to turbulence generation and, consequently, enhances the combustion efficiency. Notably, the simulation outcomes are closely aligned with the experimental values, underscoring the accuracy of the Diesel-RK software in predicting engine performance. However, it should be noted that the theoretical simulation values tend to be slightly higher than the actual values due to the omission of factors such as heat losses and friction in the simulation model. In a related study, Al-Dawody and Bhatti60 conducted a thorough investigation using the DIESEL-RK simulation software to optimize strategies for reducing nitrogen oxide (NOx) emissions in diesel engines. Their findings highlighted that a deeper piston bowl with a smaller diameter had a significant mitigating effect on NOx emissions. Similar reports were reported by Kuleshov61 with modified piston bowl having the greater turbulence shown higher performance of the diesel engine.

Conclusion

The present work explores the integration of nanotechnology and Long Short-Term Memory (LSTM) machine learning algorithms to enhance the understanding and optimization of fuel spray dynamics in compression ignition (CI) engines with varying bowl geometries.

-

The test fuel used is a quaternary fuel (50% diesel (vol%) + 5% biodiesel (vol%) + 5% vegetable oil (vol%) + 40% (vol%) pentanol) with various combustion bowl strategies such as hemispherical, toroidal, shallow depth and toroidal re-entrant chambers.

-

DBOPN-TRCC is found to exhibit 8.13% higher BTE and 8.65% lowered BSFC than the conventional HCC bowl. DBOPN-TRCC is found to have 90.16% lowered CO, 59.95% lowered HC and 15.48% lowered smoke owing to improved spray penetration and faster burning of soot precursors. However, NOx emissions of DBOPN-TRCC were found to be higher (by 10.01% in comparison with DBOPN-HCC at full load).Overall, DBOPN-TRCC blend is found to have improved performance and minimized emission characteristics.

-

The outcomes were trained and validated using LSTM networks. The regression coefficients indicate that the LSTM approach is effective in predicting both performance and emissions across a wide range of loading conditions. Application of toroidal re-entrant bowl geometry (TRCC) in quaternary fuel could be regarded as a promising substitute for traditional fossil fuels. Diesel-RK results also highlighted that a deeper piston bowl with a smaller diameter had a significant mitigating effect on NOx emissions74.

Scope for future work

The work can be extended to study the behavior of gaseous fuels or dual fuels with different combustion geometries. Also, microscopic analysis of fuel spray with photographs can be an interesting add on to the existing work.

Data availability

The datasets used and/or analysed during the current study available from the corresponding author on reasonable request.

Abbreviations

- ppm:

-

Parts per million

- nm:

-

Nano metre

- °CA:

-

Degree crank angle

- °C:

-

Celsius (degrees)

- nm:

-

Nanometer

- ppm:

-

Parts per million

- g:

-

Grams

- g/kWh:

-

Gram per kilowatt hour

- h:

-

Hour

- kg:

-

Kilogram

- kJ/kg:

-

Kilo Joules per kilogram

- kW:

-

Kilowatt

- lpm:

-

Liter per minute

- mg:

-

Milligram

- min:

-

Minutes

- m:

-

Meter

- mm:

-

Millimeter

- MPa:

-

Mega Pascal

- N.m:

-

Newton meter

- ηth :

-

Thermal efficiency

- CO:

-

Carbon monoxide

- NOX :

-

Oxides of nitrogen

- CO2 :

-

Carbon dioxide

- HC:

-

Hydrocarbon

- GHG:

-

Green house gases

- CEEMDAN:

-

Complete ensemble empirical mode decomposition with adaptive noise

- TEM:

-

Transmission electron microscopy

- RNN:

-

Recurrent neural network

- MAPE:

-

Mean absolute percentage error

- CI:

-

Compression ignition

- TCC:

-

Toroidal combustion chamber

- TiO2 :

-

Titanium oxide

- HRR:

-

Heat release rate

- DBOP:

-

Diesel-biodiesel-oil-pentanol blends

- DBOPN:

-

DBOP with 20 ppm TiO2 nano additives

- BSFC:

-

Brake specific fuel consumption

- BTE:

-

Brake thermal efficiency

- CC:

-

Combustion chamber

- BTDC:

-

Before top dead centre

- DPF:

-

Diesel particulate filter

- MAP:

-

Mean average precision

- CR:

-

Compression ratio

- CP:

-

Cylinder pressure

- RSM:

-

Response surface methodology

- ANFIS:

-

Adaptive neuro-fuzzy inference system

- IP:

-

Injection pressure

- IT:

-

Injection timing

- SEM:

-

Scanning electron microscopy

- R2 :

-

Coefficient of determination

- CRDI:

-

Common rail direct injection

- CNT:

-

Carbon nanotube

- TRCC:

-

Toroidal re-entrant combustion chamber

- HCC:

-

Hemispherical combustion chamber

- SDCC:

-

Shallow depth combustion chamber

- LSTM:

-

Long short term memory

- ANN:

-

Artificial neural network

- GA:

-

Genetic algorithm

- GRU:

-

Gated recurrent unit network

- TDNN:

-

Time delay neural network

References

Mei, Q., Liu, L., Yang, W. & Tang, Y. Combustion model development of future DI engines for carbon emission reduction. Energy. Convers. Manag. 311, 118528 (2024).

Azeez, O. S. et al. Modeling of CO emissions from traffic vehicles using artificial neural networks. Appl. Sci. 9(2), 313 (2019).

Özener, O., Yüksek, L. & Özkan, M. Artificial neural network approach to predicting engine-out emissions and performance parameters of a turbo charged diesel engine. Therm. Sci. 17 (1), 153–166 (2013).

Roy, S., Banerjee, R., Das, A. K. & Bose, P. K. Development of an ANN based system identification tool to estimate the performance-emission characteristics of a CRDI assisted CNG dual fuel diesel engine. J. Nat. Gas Sci. Eng. 21, 147–158 (2014).

Rai, A. A., Pai, P. S. & Rao, B. S. Prediction models for performance and emissions of a dual fuel CI engine using ANFIS. Sadhana 40 (2), 515–535 (2015).

Deniz, S., Gökçen, H. A. D. İ. & Nakhaeızadeh, G. Application of data mining methods for analyzing fuel consumption and emission levels. Int. J. Eng. Res. Technol. 5 (10), 1 (2016).

Uslu, S. & Celik, M. B. Performance and exhaust emission prediction of a SI engine fueled with I-amyl alcohol-gasoline blends: an ANN coupled RSM based optimization. Fuel 265, 116922 (2020).

Lu, G. et al. High performance mixed-potential type NOx sensor based on stabilized zirconia and oxide electrode. Solid State Ion. 262, 292–297 (2014).

Nishio, Y., Murata, Y., Yamaya, Y. & Kikuchi, M. Optimal calibration scheme for map-based control of diesel engines. Sci. China Inf. Sci. 61 (7), 70205 (2018).

Kurzydym, D., Żmudka, Z., Perrone, D. & Klimanek, A. Experimental and numerical investigation of nitrogen oxides reduction in diesel engine selective catalytic reduction system. Fuel 313, 122971 (2022).

Veza, I. et al. Review of artificial neural networks for gasoline, diesel and homogeneous charge compression ignition engine. Alexand. Eng. J. 61 (11), 8363–8391 (2022).

Ragaller, P. et al. Particulate Filter Soot Load Measurements Using Radio Frequency Sensors and Potential for Improved Filter Management (No. 2016-01-0943). SAE Technical Paper (2016).

Liu, B., Hu, J., Yan, F., Turkson, R. F. & Lin, F. A novel optimal support vector machine ensemble model for NOx emissions prediction of a diesel engine. Measurement 92, 183–192 (2016).

Jiang, K., Cao, E. & Wei, L. NOx sensor ammonia cross-sensitivity estimation with adaptive unscented Kalman filter for Diesel-engine selective catalytic reduction systems. Fuel 165, 185–192 (2016).

Shin, S. et al. Designing a steady-state experimental dataset for predicting transient NOx emissions of diesel engines via deep learning. Expert Syst. Appl. 198, 116919 (2022).

Feizizadeh, B., Omarzadeh, D., Kazemi Garajeh, M., Lakes, T. & Blaschke, T. Machine learning data-driven approaches for land use/cover mapping and trend analysis using Google Earth Engine. J. Environ. Plann. Manag. 66 (3), 665–697 (2023).

Planakis, N., Papalambrou, G., Kyrtatos, N. & Dimitrakopoulos, P. Recurrent and Time-Delay Neural Networks as Virtual Sensors for Nox Emissions in Marine Diesel Powertrains (No. 2021-01-5042). SAE Technical Paper (2021).

Shin, S. et al. Deep neural network model with Bayesian hyperparameter optimization for prediction of NOx at transient conditions in a diesel engine. Eng. Appl. Artif. Intell. 94, 103761 (2020).

Yurtsever, E., Lambert, J., Carballo, A. & Takeda, K. A survey of autonomous driving: Common practices and emerging technologies. IEEE Access 8, 58443–58469 (2020).

Li, J., Yang, W. M., An, H., Maghbouli, A. & & Chou, S. K. Effects of piston bowl geometry on combustion and emission characteristics of biodiesel fueled diesel engines. Fuel 120, 66–73 (2014).

Hirschberg, J. & Manning, C. D. Advances in natural language processing. Science 349 (6245), 261–266 (2015).

Cambria, E. & White, B. Jumping NLP curves: A review of research in natural language processing. IEEE Comput. Intell. Mag. 9 (2), 48–57 (2014).

Wang, M. & Deng, W. Deep face recognition: A survey. Neurocomputing 429, 215–244 (2021).

Razali, N. A. M. et al. Gap, techniques and evaluation: traffic flow prediction using machine learning and deep learning. J. Big Data 8 (1), 1–25 (2021).

Ramteke, S. M., Chelladurai, H. & Amarnath, M. Diagnosis and classification of diesel engine components faults using time–frequency and machine learning approach. J. Vib. Eng. Technol. 10 (1), 175–192 (2022).

Atkinson, C. M., Long, T. W. & Hanzevack, E. L. Virtual Sensing: A Neural Network-Based Intelligent Performance and Emissions Prediction System for On-Board Diagnostics and Engine Control (No. 980516). SAE Technical Paper (1998).

Traver, M. L., Atkinson, R. J. & Atkinson, C. M. Neural Network-Based Diesel Engine Emissions Prediction Using In-Cylinder Combustion Pressure. SAE Transactions 1166–1180 (1999).

He, Y. & Rutland, C. J. Application of artificial neural networks in engine modelling. Int. J. Engine Res. 5 (4), 281–296 (2004).

Arsie, I., Marra, D., Pianese, C. & Sorrentino, M. Real-time estimation of engine NOx emissions via recurrent neural networks. IFAC Proc. Vol. 43 (7), 228–233 (2010).

Alcan, G. et al. Predicting NOx emissions in diesel engines via sigmoid NARX models using a new experiment design for combustion identification. Measurement 137, 71–81 (2019).

Yu, Y. et al. A novel deep learning approach to predict the instantaneous NO2 emissions from diesel engine. IEEE Access 9, 11002–11013 (2021).

Van Hung, T., Alkhamis, H. H., Alrefaei, A. F., Sohret, Y. & Brindhadevi, K. Prediction of emission characteristics of a diesel engine using experimental and artificial neural networks. Appl. Nanosci. 1, 1–10 (2021).

Xie, H. et al. Parallel attention-based LSTM for building a prediction model of vehicle emissions using PEMS and OBD. Measurement 185, 110074 (2021).

Castresana, J., Gabiña, G., Martin, L., Basterretxea, A. & Uriondo, Z. Marine diesel engine ANN modelling with multiple output for complete engine performance map. Fuel 319, 123873 (2022).

Saito, T., Daisho, Y., Uchida, N. & Ikeya, N. Effects of Combustion Chamber Geometry on Diesel Combustion. SAE Transactions 793–803 (1986).

Zhu, Y., Zhao, H., Melas, D. A. & Ladommatos, N. Computational Study of the Effects of the Re-entrant Lip Shape and Toroidal Radii of Piston Bowl on a HSDI Diesel Engine’s Performance and Emissions (No. 2004-01-0118). SAE Technical Paper (2004).

Dolak, J. G., Shi, Y. & Reitz, R. D. A Computational Investigation of Stepped-Bowl Piston Geometry for a Light Duty Engine Operating at Low Load (2010-01-1263). SAE Technical Paper (2010).

Lim, J. & Min, K. The Effects of Spray Angle and Piston Bowl Shape on Diesel Engine Soot Emissions Using 3-D CFD Simulation (No. 2005-01-2117). SAE Technical Paper (2005).

Shi, Y. & Reitz, R. D. Optimization study of the effects of bowl geometry, spray targeting, and swirl ratio for a heavy-duty diesel engine operated at low and high load. Int. J. Engine Res. 9 (4), 325–346 (2008).

Wickman, D. D., Yun, H. & Reitz, R. D. Split-Spray Piston Geometry Optimized for HSDI Diesel Engine Combustion. SAE Transactions 488–507 (2003).

Sivakumar, M., Sundaram, N. S. & Thasthagir, M. H. S. Effect of aluminium oxide nanoparticles blended pongamia methyl ester on performance, combustion and emission characteristics of diesel engine. Renew. Energy 116, 518–526 (2018).

Ranjan, A. et al. Experimental investigation on effect of MgO nanoparticles on cold flow properties, performance, emission and combustion characteristics of waste cooking oil biodiesel. Fuel 220, 780–791 (2018).

Mehregan, M. & Moghiman, M. Effects of nano-additives on pollutants emission and engine performance in a urea-SCR equipped diesel engine fueled with blended-biodiesel. Fuel 222, 402–406 (2018).

El-Seesy, A. I., Attia, A. M. & El-Batsh, H. M. The effect of Aluminum oxide nanoparticles addition with Jojoba methyl ester-diesel fuel blend on a diesel engine performance, combustion and emission characteristics. Fuel 224, 147–166 (2018).

Hoseini, S. S. et al. Novel environmentally friendly fuel: The effects of nanographene oxide additives on the performance and emission characteristics of diesel engines fuelled with Ailanthus altissima biodiesel. Renew. Energy 125, 283–294 (2018).

Kumar, S., Dinesha, P. & Bran, I. Influence of nanoparticles on the performance and emission characteristics of a biodiesel fuelled engine: an experimental analysis. Energy 140, 98–105 (2017).

Ashok, B., Nanthagopal, K., Mohan, A., Johny, A. & Tamilarasu, A. Comparative analysis on the effect of zinc oxide and ethanox as additives with biodiesel in CI engine. Energy 140, 352–364 (2017).

Das, M., Sarkar, M., Datta, A. & Santra, A. K. Study on viscosity and surface tension properties of biodiesel-diesel blends and their effects on spray parameters for CI engines. Fuel 220, 769–779 (2018).

Liu, Y. et al. Spray characteristics of biodiesel-polyoxymethylene dimethyl ethers (PODE) blends in a constant volume chamber. Combust. Sci. Technol. 195 (16), 4069–4091 (2023).

Chaudhari, V. D., Kulkarni, A. & Deshmukh, D. Spray characteristics of biofuels for advance combustion engines. Clean. Eng. Technol. 5, 100265 (2021).

Park, S. H., Suh, H. K. & Lee, C. S. Effect of bioethanol–biodiesel blending ratio on fuel spray behavior and atomization characteristics. Energy Fuels 23 (8), 4092–4098 (2009).

Geng, L., Wang, Y., Wang, Y. & Li, H. Effect of the injection pressure and orifice diameter on the spray characteristics of biodiesel. J. Traffic Transp. Eng. (English Ed.) 7 (3), 331–339 (2020).

Li, F. et al. Comparison of macroscopic spray characteristics between biodiesel-pentanol blends and diesel. Exp. Thermal Fluid Sci. 98, 523–533 (2018).

Zhang, P. et al. Spray, atomization and combustion characteristics of oxygenated fuels in a constant volume bomb: A review. J. Traffic Transp. Eng. (English Ed.) 7 (3), 282–297 (2020).

Raghu, P., Thilagan, K., Thirumoorthy, M., Lokachari, S. & Nallusamy, N. Spray characteristics of diesel and biodiesel in direct injection diesel engine. Adv. Mater. Res. 768, 173–179 (2013).

Appavu, P. & Venu, H. Quaternary blends of diesel/biodiesel/vegetable oil/pentanol as a potential alternative feedstock for existing unmodified diesel engine: Performance, combustion and emission characteristics. Energy 186, 115856 (2019).

Venu, H., Subramani, L. & Raju, V. D. Emission reduction in a DI diesel engine using exhaust gas recirculation (EGR) of palm biodiesel blended with TiO2 nano additives. Renew. Energy 140, 245–263 (2019).

Venu, H., Raju, V. D. & Subramani, L. Combined effect of influence of nano additives, combustion chamber geometry and injection timing in a DI diesel engine fuelled with ternary (diesel-biodiesel-ethanol) blends. Energy 174, 386–406 (2019).

Liu, Y. et al. Machine learning based predictive modelling of micro gas turbine engine fuelled with microalgae blends on using LSTM networks: An experimental approach. Fuel 322, 124183 (2022).

Al-Dawody, M. F. & Bhatti, S. K. Optimization strategies for mitigating the biodiesel NOX effect in diesel engines with experimental verification. Energy. Convers. Manag. 68, 96–104. https://doi.org/10.1016/j.enconman.2012.12.025 (2013).

Kuleshov, A. & Multi-Zone DI Diesel Spray Combustion Model and Its Application for Aligning Injector Design with Piston Bowl Shape. SAE Technical Paper 2007-01-1908. https://doi.org/10.4271/2007-01-1908 (2007).

Venu, H., Raju, D., Subramani, L. & V and Combined effect of influence of nano additives, combustion chamber geometry and injection timing in a DI diesel engine fuelled with ternary (diesel-biodiesel-ethanol) blends. Energy 174, 386–406. https://doi.org/10.1016/j.energy.2019.02.163 (2019).

Jaichandar, S. & Annamalai, K. Effects of open combustion chamber geometries on the performance of pongamia biodiesel in a DI diesel engine. Fuel 98, 272–279 (2012).

Lalvani, J. I. J., Parthasarathy, M., Dhinesh, B. & & Annamalai, K. Pooled effect of injection pressure and turbulence inducer piston on performance, combustion, and emission characteristics of a DI diesel engine powered with biodiesel blend. Ecotoxicol. Environ. Saf. 134, 336–343 (2016).

Mamilla, V. R. et al. Effect of combustion chamber design on a DI diesel engine fuelled with jatropha methyl esters blends with diesel. Procedia Eng. 64, 479–490 (2017).

Bapu, B. R., Saravanakumar, L. & Prasad, B. D. Effects of combustion chamber geometry on combustion characteristics of a DI diesel engine fueled with CalophyllumInophyllum methyl ester. J. Energy Inst. 90 (1), 82–100 (2017).

Venkateswaran, S. P. & Nagarajan, G. Effects of the re-entrant bowl geometry on a DI turbocharged diesel engine performance and emissions—a CFD approach. J. Eng. Gas Turbines Power 132, 12 (2010).

Benajes, J., Pastor, J. V., García, A. & Monsalve-Serrano, J. An experimental investigation on the impact of piston bowl geometry on RCCI performance and emissions in a heavy-duty engine. Energy. Convers. Manag. 103, 1019–1030 (2015).

Dolak, J. G., Shi, Y. & Reitz, R. D. A Computational Investigation of Stepped-Bowl Piston Geometry for a Light-Duty Engine Operating at Low Load. SAE Technical Paper, No. 2010-01-1263 (2010).

Jaichandar, S., Kumar, P. S. & Annamalai, K. Combined impact of injection timing and combustion chamber geometry on the performance of a biodiesel-fueled diesel engine. Energy 47, 388–394 (2012).

Wei, S., Wang, F., Leng, X., Liu, X. & Ji, K. Numerical analysis on the effect of swirl ratios on swirl chamber combustion system of DI diesel engines. Energy. Convers. Manag. 75, 184–190 (2013).

Prasad, B. V. V. S. U., Sharma, C. S., Anand, T. N. C. & Ravikrishna, R. V. High swirl-inducing piston bowls in small diesel engines for emission reduction. Appl. Energy 88, 2355–2367 (2011).

Lim, J. & Min, K. The Impact of Spray Angle and Piston Bowl Shape on Diesel Engine Soot Emissions Using 3-D CFD Simulation. In SAE Technical Paper, No. 2005-01-2117 (2005).

Mei, Q., Liu, L. & Mansor, M. R. A. Investigation on spray combustion modeling for performance analysis of future low-and zero-carbon DI engine. Energy 1, 131906 (2024).

Acknowledgements

This study has been supported by the Recep Tayyip Erdogan University Development Foundation through the grant number 02025001002235.

The authors extend their appreciation to the Deanship of Scientific Research at King Khalid University, Saudi Arabia for funding this work through the Research Group Program under Grant No: RGP 2/127/45.

This work was supported by Tenaga Nasional Berhad (TNB) and UNITEN through the BOLD Refresh Postdoctoral Fellowships under Grant J510050002-IC-6 BOLDREFRESH2025-Centre of Excellence.

Author information

Authors and Affiliations

Contributions

Conceptualization—Harish Venu, Tiong Sieh Kiong; Investigation—Harish Venu and N.M. Razali; Methodology—Armin Rajabi, Hua-Rong Wei; Supervision, Validation—Tiong Sieh Kiong; Writing—original draft, Harish Venu and N.M. Razali; Review & editing-Armin Rajabi, Manzoore Elahi M. Soudagar, Erdem Cuce, V. Dhana Raju, and Naif Almakayeel. Funding acquisition—T. M. Yunus Khan.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Venu, H., Soudagar, M.E.M., Kiong, T.S. et al. Nanotechnology and LSTM machine learning algorithms in advanced fuel spray dynamics in CI engines with different bowl geometries. Sci Rep 15, 983 (2025). https://doi.org/10.1038/s41598-024-83211-y

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-024-83211-y